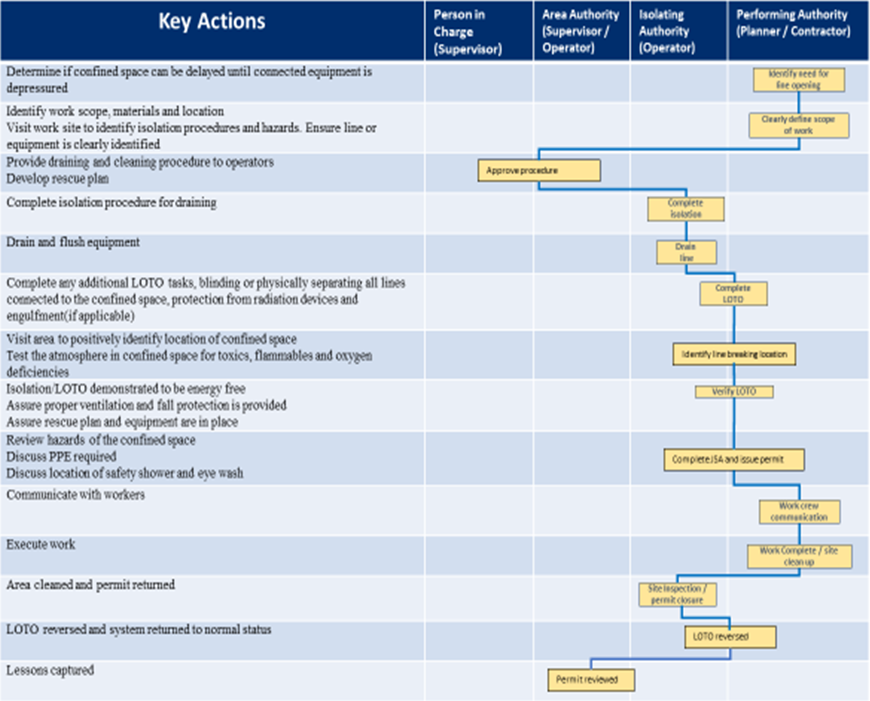

Person In Charge

Is responsible for the Operation of the Plant. This is typically a Site Manager whose responsibilities include:

- Overall responsibility for the execution of the Permit to Work system.

- Ensuring the system is subject to regular monitoring and auditing.

- Ensuring competent people are fulfilling the specified roles of the process

- Responsible for ensuring the process is properly documented

- Ensuring any intended deviations from approved procedures are properly planned and approved by the appropriate Technical Authorities.

- Ensuring the daily workload is capable of being safely executed by the available staff and contractor resources.

Area Authority

Is responsible for managing a Unit or section of the Plant. This is typically the Shift Supervisor whose responsibilities include:

- Ensuring the planned work activities are executed in a safe and timely manner.

- Managing all permitted work in the area.

- Ensuring an appropriate risk assessment or JSA for work is carried out and the appropriate control measures are specified and implemented.

- Developing a confined space entry rescue plan

- Approval of isolation design and control of isolation implementation and reinstatement.

- Ensuring worksite inspections are carried out before, during and after the performance of this task (maybe delegated)

- Ensuring adequate handovers are carried out at shift change

- Maintaining the long-term isolation register

- Managing all simultaneous operations in accordance with company policies.

Isolating Authority (Area Operator)

Is responsible for isolating specific sections of the plant in accordance with company standards. This is typically the Area Operator whose responsibilities include:

- Designing the isolation scheme

- Obtaining approval of the isolation scheme and permission to take equipment off line and to implement the isolation points.

- Depressurizing, draining and purging the equipment to ensure it is chemical free and safe for confined space entry.

- Implementing isolation points and appropriately labelling them and securing the isolation points using approved methods.

- Reviewing the implemented isolation scheme with the Performing Authority and demonstrating energy free status.

- An Area Operator may also act as Approved Gas Tester to carry out tests for flammable vapors, toxic gasses and Oxygen on all activities including line breakages, hot work and confined space work.

- As an Area Operator responsible for visiting the work site, identifying hazards and necessary controls to be specified on the permit and ensuring all appropriate control measures are in place before work starts and that the worksite is safe for work activities specified in the work permit.

- As an Area Operator responsible for periodic surveillance of the worksite and the ongoing work activities.

- Reinstating isolations and returning equipment into service on the plant

- As an Area Operator ensuring the worksite is safe, clean and tidy after the permit has been returned.

- Note that for electrical isolations, properly certified Responsible Electrical Persons will be required to properly isolate, label and secure electrical equipment.

Performing Authority (Contractor)

Is the responsible person for the activity being carried out under the authority of the permit? This is typically the person whose responsibilities include:

- Initiating the permit, typically in response to a maintenance work order.

- Visiting the worksite and identifying any hazards which need to be properly controlled during the work task.

- Participating in any risk assessment activity associated with the work task preparations.

- Signing for the permit when issued and ensuring that all requirements and instructions of the permit are followed.

- Receiving briefing instructions for the Area Operator on Process Safety hazards and controls in place including any isolation controls.

- Conducting a “Toolbox talk” with all assembled work party members. Ensuring they understand the work instructions and the conditions of the Permit. Pointing out specific hazards and identifying how they will be managed for the duration of the work activity. Explaining contingency plans in the event of an emergency. Ensuring all work party members sign onto the work permit.

- Managing the conduct of the work in accordance with the work order and the permit. Making sure continuous or periodic gas checks are conducted as specified in the permit.

- In the event of an emergency or a general alarm, ensuring the work ceases immediately. The work site is made safe and that the work party go immediately to their muster point.

- Ensuring the worksite is maintained in a safe and tidy manner during the work activities and that when the work is complete, the site is cleared of all tools and properly cleaned before the work permit is signed off and returned to the control point.