Filtration and Separations

Dust Filter Meets Sanitary Standards

The Hygienic Round Top Removal (HRT) filter is a pulse-jet filter designed for dust collection in low-capacity pneumatic conveying systems. The unit has a top-hinged dome and uses snap-band filter bags, allowing operators to quickly remove and change bags without tools or the need to enter the dirty portion of the filter. The filter comes in two styles: Style II (without a hopper) and Style III (with a 60-deg. hopper). Style II is used as a bin vent filter for storage tanks, work bins, and surge hoppers. Style III collects dust through the hopper inlet and discharges the collected dust through an airlock for recycling or disposal. The bag cages and diaphragm are made of Type 304 stainless steel, and the interior and exterior finishes, as well as the bags, comply with sanitary standards. Additional options include a differential-pressure transmitter, sanitary ferrule inlet and exhaust connections, and explosion vents.

Schenck Process

Membranes Improve Low-Pressure Reverse Osmosis

The Lewabrane ultra-low-pressure (ULP) reverse osmosis technology is available with three different filters, B085 ULP 4040, B400 ULP ASD, and B440 ULP, all of which have a high degree of impermeability to organic compounds, a high permeability to water, and a low energy demand. The alternating strand design (ASD) in the B400 ULP ASD’s feed spacer resists fouling, improving the membrane’s service life and cost performance. The B440 ULP is the company’s most productive reverse osmosis membrane and is suitable for compact systems. All membranes are wet-tested, made of a composite polyamide, and designed for low-salinity and low-operating-pressure applications.

Lanxess

Bioprocessing

DNA Extraction Method Maintains Sample Integrity

The ID NIMBUS automates post-polymerase chain reaction (PCR) sample processing. The system increases throughput of DNA extraction while maintaining a high degree of sample integrity, so users can have confidence in the results. Autoinitiated extraction improves overall operating efficiency by allowing analysts to redirect their efforts to other activities. The compact and easy-to-load instrument has four independent pipetting channels and an ISO-certified positive-pressure chamber with UV and high-efficiency particulate air (HEPA) filters. In addition, liquid-sensing technology ensures that there is no splatter or aerosolizing upon injection of the tip into the sample. The analyzer is highly sensitive and can handle degraded DNA, low-quality DNA, or complex DNA mixtures.

Hamilton Robotics

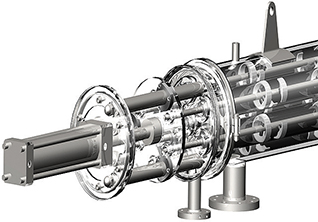

Scraper Design Aids Heat Transfer

Unicus heat exchangers are specifically designed for heat transfer involving complex materials or viscous, highly fouling fluids such as those found in bioenergy applications like the thermal and chemical pretreatment of biomass, thermal hydrolysis, and oil extraction. The scraped-surface heat exchanger increases turbulence and reduces fouling, thus overcoming challenges typically associated with simple plate and tubular exchangers. The heat exchangers are available with a variety of scraper types. Because the scraper’s hydraulic mechanism does not contact the process fluid, the exchanger is compatible with fluids of all types, including those that are susceptible to shear stress or pressure damage, as well as those containing large particulates. The Unicus Series prevents leakage, is scalable, and can be run in a continuous operation, increasing plant productivity. Standard models for industrial use have heat transfer areas of 0.7 m2 to 10 m2, and models with heat transfer areas up to 120 m2 can be made for specific requirements.

HRS Heat Exchangers

Customizable Bioreactor Eases Production Growth

The large-scale single-use microbial fermentation Custom Single Run (CSR) technology improves production scaleup for bioreactors. The bioreactor is available in customizable volumes of 50–4,000 L and is suitable for cell cultures. The vessel has a low risk of container failure and a fast system turnaround.

ABEC

Automation Facilitates Cell Culture Scaleup

The ambr 250 high-throughput perfusion is an automated parallel bioreactor system designed to optimize production of therapeutic antibodies through rapid cell culture process development. A single automated workstation controls 12 or 24 mini perfusion bioreactors of 100–250-mL working volumes. High-efficiency spargers, perfusion pump chambers, and an industry standard hollow-fiber filter for cell retention enable intensified cell culture processing. Geometric similarity between the mini perfusion bioreactors and pilot and manufacturing bioreactors eases scale-up optimization and shortens the development timeline. This system is less expensive and carries out perfusion culture experiments in less time than bench-top or fed-batch reactors, and is useful for a wide variety of biopharma and industrial biotech applications.

Sartorius Stedim

Fluids and Solids Handling

Scanning System Maps Material Levels

The 3DLevelScanner acoustic sensor measures the levels of materials piled under structures. A multiple-scanner installation is paired with MultiVision software to virtually separate the material into sections with lengths as small as 1.5 m. The continuously operating system measures changes in the minimum, maximum, and average levels in each section and displays the topography of the entire storage bunker or warehouse. The scanner system is recommended for copper, alumina, corn, coal, or other ores, aggregates, or grains stored in covered structures.

Binmaster

Leakproof Valve Reduces Contamination

The Unique Mixproof valve comes in High Alloy and UltraPure models to meet industry needs. The valves have two independent plugs, a double-seat design, and built-in leakage detection to reduce the risk of product contamination, as well as reduce costs. The High Alloy models have a higher corrosion resistance than other models while maintaining a high degree of product safety and a long equipment lifetime, which reduce production downtime. The UltraPure model comes with the Q-doc package to ensure full traceability, and a seal that meets U.S. Food and Drug Administration (FDA), U.S. Pharmacopeia (USP) Class VI, and Transmissible Spongiform Encephalopathy (TSE)/No Animal Derived Ingredient (ADI) requirements. The valves are suitable for aggressive-corrosion applications, including buffer solutions, cleaning liquids, and high-salt solutions. They are designed specifically to meet the needs of hygienic manufacturing industries that produce food, beverage, pharmaceutical, and home and personal care products.

Alfa Laval

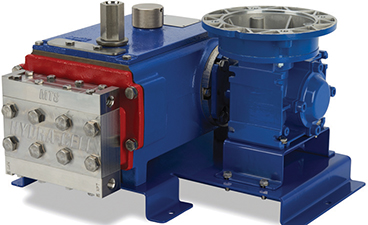

Versatile Metering Pump Creates Pulse-Free Flow

The Hydra-Cell Metering Solutions Model MT8 triplex metering pump can handle a variety of fluids at low flowrates and high pressures. Multiple diaphragms provide a virtually pulse-free flow while an integral relief valve protects the pump from overpressurization. Flowrates through the pump can range from 0.06 gpm to 8 gpm with discharge pressures up to 3,500 psi for metallic pump heads and 350 psi for nonmetallic pump heads. The MT8 triplex contains no mechanical or dynamic seals, cups, or packing to leak, wear, or replace, which extends its lifetime and reduces the need for production downtime for maintenance. All models are available with pump head options made from Type 316L stainless steel, Alloy 20, Hastelloy C, polyvinyl chloride (PVC), or polyvinylidene fluoride (PVDF). The pump has a small footprint and provides fast, simple, conversions with the Hydra-Cell Metering Solutions Control Freak TM touchscreen metering controller. It complies with American Petroleum Institute (API) 675 performance standards for steady-state accuracy, linearity, and repeatability. The pump is suitable for oil and gas (onshore and offshore) applications, water and wastewater treatment, chemical injection, polyurethane foam processing, pharmaceutical applications, power generation, and plastics processing.

Wanner Engineering

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.