Clean and efficient transportation can become a reality for everyone with hydrogen fuel cell electric vehicles.

Hydrogen fuel cell electric vehicles (HFCEVs) are more energy efficient than conventional gasoline internal combustion engine vehicles (ICEVs), which are limited by the Carnot thermal engine efficiency, and they produce no tailpipe emissions other than water vapor. Hydrogen fuel can be produced from a variety of non-fossil and renewable feedstocks that are widely available, and could help to reduce the transportation sector’s dependence on petroleum-based fuels and increase the security of the energy supply.

Hydrogen fuel cell electric vehicles

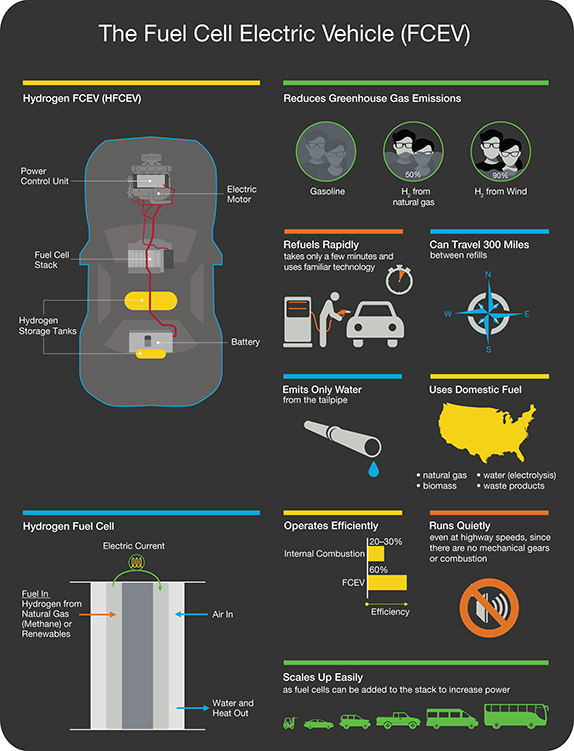

A HFCEV consists of six major components: a hydrogen storage tank, air intake system, fuel cell stack, power control unit, battery, and electric motor. The HFCEV uses proton exchange membrane (PEM) fuel cell technology to convert the chemical energy of hydrogen into electricity. Hydrogen from the onboard storage tank reacts with oxygen pulled in through the air intake system to generate electricity via an electrochemical process that occurs in the fuel cell stack. The only byproduct of the process is water vapor, which exits the fuel cell stack into the atmosphere.

The electricity the fuel cell generates is managed by the power control unit, which conditions the electricity and either charges the battery, powers the motor, or both. Although the battery is not a major source of power for the HFCEV, it is used to store excess electricity, allows the fuel cell to operate near its peak efficiency, and supports other functions of the vehicle. The electric motor converts the electric energy into mechanical energy, propelling the vehicle (1).

Although current gasoline-powered vehicle technologies have shorter fueling times and longer driving ranges than many of the alternative zero-emission vehicle technologies, they produce tailpipe emissions, such as greenhouse gases (GHGs). HFCEVs can achieve fueling times and driving ranges similar to those of gasoline ICEVs while eliminating tailpipe emissions and reducing the well-to-wheels (WTW) GHG emissions (2). HFCEVs are able to provide a consumer experience similar to that of gasoline-powered vehicles, while reducing the environmental impacts of the transportation sector.

One drawback of hydrogen as a fuel is that because it has a low molecular weight and low density, it must be stored at high pressures onboard the vehicle to enable a driving range comparable to that of gasoline-powered vehicles. Various technologies have been explored to store hydrogen at various states, including cryo-compressed hydrogen (CcH2) at 350 bar, gaseous hydrogen at 350 bar, and gaseous hydrogen at 700 bar. Hydrogen storage tanks have evolved from all-metal tanks (Type I), metal hoop-wrapped composite tanks (Type II), and metal-lined composite tanks (Type III) to plastic-lined composite tanks (Type IV). The 700-bar Type IV tank for onboard storage is the only option currently certified for use by all HFCEV manufacturing companies (3).

Fueling

The Society of Automotive Engineers (SAE) has developed protocols to control the fueling process (4), and fuel station developers are building facilities to fuel 700-bar HFCEVs using those standardized fueling protocols. The fueling protocol, SAE J2601, establishes a set of performance parameters that need to be met and maintained in order to dispense the necessary amount of hydrogen in the shortest possible time while ensuring the safety of the filling process.

The thermal diffusivity of a Type IV tank is very low, enabling a near-adiabatic fueling process. The increase in pressure during the short fueling event raises the temperature of hydrogen within the tank considerably (5). Type IV, 700-bar tanks have a maximum operating temperature of 85°C. At that temperature, the corresponding fill pressure can be as high as 875 bar at the end of a fill. To keep the temperature in the vehicle’s tank below 85°C and also enable fast fueling within 3 to 5 min, hydrogen is precooled to –40°C before it is dispensed. The SAE J2601 protocol considers the tank characteristics, station precooling capabilities, and ambient temperature in determining...

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.