Heat Transfer

Cooling Tower Packing Reduces Harmful Bacterial Growth

SaniPacking fills and drift eliminators for wet cooling towers prevent the growth of bacteria, including Legionella pneumophilia, as well as Pseudomonas aeruginosa, the most common species found in industrial cooling water biofilm. When they are properly maintained, the antimicrobial effect can last for three to five years. The tough, impact-resistant, pressure-stable fills and drift eliminators consist of polypropylene films that are sealed and welded together to form secure modules with a cross-fluted structure. The honeycomb-shaped modules can operate consistently at hot-water temperatures up to 80°C and can handle temperatures up to 90°C for short periods of time. The lightweight material does not contain arsenic or heavy metals, and it is resistant to corrosion, UV radiation, most chemicals, fouling, and fungal growth. The fills and drift eliminators are available in various designs, all meeting International Organization for Standardization ISO 22196 and ISO 846 standards for its antimicrobial and antifungal properties, respectively.

ENEXIO

Insulators are Available in a Variety of Configurations

The Silver Series insulators offer flexible heating, insulating, and temperature control for a wide variety of applications in the petrochemical, aerospace, construction, oil and gas, plastics, and other industries. This configurable system features durable cloth made from FRC1650 polymer-coated fiberglass that is moisture- and chemical-resistant, and fire-retardant. The insulation is 1-in.-thick needle-punched fiberglass and is suitable for general-purpose insulation. The insulators have a self-regulating heating cable and a constant-wattage heating cable. Versions of the insulators are available for straight pipes, valves, elbows, T-connections, and flanges, and custom shapes and sizes can be manufactured to meet unique requirements. Hook-and-loop closures ease installation on pipes, tanks, vessels, or steam lines. The insulators protect employees from burns and reduce energy consumption. They are suitable for operation at up to 450°F (232°C) and have an Ingress Protection (IP) IP54 rating for protection against dust and water.

BriskHeat

Scraped-Surface Heat Exchanger Improves Handling of Viscous Fluids

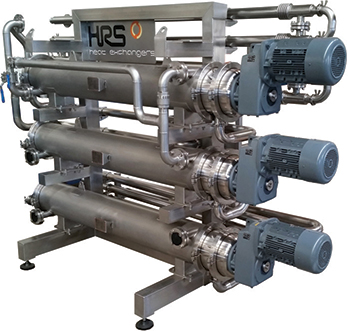

The R Series rotating scraped-surface heat exchanger can handle fluids with extremely high fouling potential in sanitary and industrial applications. It uses a rotary scraper-rod capable of reaching velocities of 300 rpm to deliver high levels of shear mixing, increase heat-transfer rates, and provide constant agitation to keep solid particles in suspension. The scraper rod features both a helical mixing spiral and a series of scraper blades. The exchanger’s design enables high-viscosity products to be pumped at lower pressure and using less energy. The gearbox design reduces noise and allows multiple tubes to be fitted inside a single shell from a single electrical drive, further increasing the available heat-transfer area within the same shell footprint. The sealing system allows individual tubes to be removed for servicing and replacement, easing cleaning and maintenance. Most of the product can be emptied from the exchanger without the need for any additional pumps or pressure systems, reducing capital and operating costs. It is available in two lengths (1 m and 2 m) and with one-, three-, or six-tube options, providing a range of surface areas between 0.35 m2 and 4.2 m2; for larger installations, multiple units can be combined in series. The exchanger can be mounted horizontally or vertically, and internal baffles within the tubes can overcome shellside flow limitations. The heat exchanger is suitable for a variety of uses in the food processing and cosmetic industries, including heating, cooling, pasteurization, crystallization, and evaporation.

HRS Heat Exchangers

Instrumentation

Family of Pocket Sensors Handles Multiple Tests

These durable pocket sensors test water quality in the lab or out in the field. An intuitive interface makes it simple to obtain reliable measurements. An easy-to-replace sensor module and a dependable double-junction pH electrode sensor extend the service life. The leakproof cap stabilizes the base to keep the tester standing upright, stores solution so the electrode remains hydrated, and can function as a sample cup for calibration or measurement. The pHTestr 50 sensor features automatic temperature compensation, three-point calibration, and 0.01 pH resolution to ensure an accurate reading. The pHTestr 50S spear-tip sensor is rugged and can analyze the water content of soft solids and semisolid materials such as food. The ORPTestr 50 sensor has a double-junction platinum electrode for checking dirty water, heavy metals, sulfides, and organics. The CTSTestr 50 sensor measures conductivity, total dissolved solids (TDS), and salinity, and it is available in either a cup or pin style. The PCTSTestr 50 multiparameter tester measures pH, conductivity, TDS, salinity, and temperature. It includes a long-life pH electrode and stainless steel pin-style conductivity sensor that make it compatible with many types of samples. All of the models are dustproof and waterproof with an Ingress Protection (IP) IP67 rating. A rugged plastic body enables these pocket testers to work in harsh environments.

Cole Parmer

Limit Switches Boast a Long Lifespan

The ES 98 and EM 98 Series limit switches provide slow-action and snap-action positive-break normally closed (NC) contacts, respectively. The connections are screw terminals with silver contact surfaces. The actuating head can be rotated in 90-deg. increments up to four times and the rocking lever is adjustable in 10-deg. increments. The rugged, corrosion-resistant, glass-fiber-reinforced thermoplastic housing has Ingress Protection (IP) ratings of IP66, IP67, or IP69K to ensure reliable operation even when dust and water pose threats. In addition to the IP ratings, the switches are also cCSAus certified, comply with EN ISO 13489-1, and have a B10d value of 2 million. The switches operate from –20°C to 90° C. They are available with a variety of actuator styles, including plunger, roller plunger, roller lever, and rocking lever.

Steute Wireless

Solids Handling

Solids Mixer Evenly Distributes Added Liquid

The Model 700-TH-140-SS rotary batch mixer has an integral spray line that uniformly distributes liquid being added to dry bulk solids. Liquid can be sprayed over a wide expanse of moving material to ensure a uniform batch. Proprietary mixing flights of the rotating drum tumble, turn, cut, and fold material, creating free space between particles, which recombine 288 times per minute. The mixer is equipped with a sliding intake chute which, together with twin doors on opposite sides of the mixing vessel, provide rapid access to the interior, intake spout, and seal area for cleaning, sanitizing, and visual inspection of all material-contact surfaces. In addition to blending, the flights direct material toward and through a stationary, pneumatically actuated plug-gate valve for total discharge, eliminating residual material that would otherwise be wasted or require manual removal prior to cleaning. The mixer has a total capacity of 271 ft3 (7.67 m3), and a batch capacity of 140 ft3 (3.96 m3). It is effective at blending batches from 100% of the rated capacity to as low as 5% without liquid addition, and to 33% with liquid addition. The rotating drum is supported by two oversized trunnion rings that ride on heavy-duty alloy roller assemblies, eliminating the need for an internal shaft, minimizing maintenance requirements, and providing a long system life. To contain dust, the machine has one seal at the inlet, which is mounted externally to allow rapid replacement. Constructed of sanitary stainless steel, the mixer is intended for dry bulk blending, with or without the addition of coatings, flavorings, vitamins, other food products, or active liquid ingredients.

Munson Machinery

High-Capacity Sifter Enables Easy Cleaning and Maintenance

The ATLAS gyratory sifter performs high-capacity screening in a low-maintenance, operator-friendly design. The uniform horizontal motion of the sifter provides sharp separations for large volumes and easy screen cleaning. The low dynamic force allows for a high degree of material spreadability. The sifter is available in 33 configurations with up to 12 screens that have a surface area ranging from 32 ft² (3 m²) to 792 ft² (73.5 m²). Engineered for maximum uptime and ease of use, each screener incorporates basket hangers and a drive system that does not require relubricating. All of the models integrate technology that allows one-minute screen changes from either the feed end or the discharge end of the machine. This reduces equipment downtime and increases the system’s production capacity. The sifters also feature a high-performance feed box, discharge door, and superior deblinding ball action. The sifters are suitable for use in a variety of industries, including chemical, food, plastics, agriculture, minerals, pharmaceuticals, and paper.

SWECO

Mill Handles a Wide Variety of Materials

The Model CGM 750 cone mill gently grinds fatty, heat-sensitive, sticky, moist, or fragile materials into uniformly sized particles at rates up to 35 ton/hr (32 m.t./hr). Vertical material flow and low-energy grinding action with short residence times produce tight particle size distributions from 125 μm to 250 μm, without the noise, dust, product build-up or heat generation associated with traditional mills. Designed for bulk pharmaceuticals, foods, and contamination-sensitive chemicals, the sanitary unit is suitable for wet and dry milling, preconditioning, and de-agglomerating of a wide range of bulk products. Bulk material is fed by gravity or by a vacuum conveying system into a central milling chamber. There, a rotating impeller accelerates the material centrifugally against and through apertures in a conical screen. The ground particles then fall into a receptacle below the milling chamber. A pneumatic, swing-down conical discharge chute with quick-release clamps allows easy lowering of the 250-lb (114-kg) cone housing and full access to the housing interior, beater, and perforated conical screen for cleaning and sanitizing. Conical screens with round, square, or raised-lip (resembling a cheese grater) perforations can be changed rapidly and are offered with apertures from 150 μm for fine/dry de-agglomeration up to 25 mm for wet granulation. Constructed of Type 304 or Type 316 stainless steel to sanitary or industrial standards, the mill is top-driven by a belt drive. Fully interlocked moving components with a time-delay function ensure operator safety. This model has a diameter of 29.5 in. (750 mm); smaller models are available for laboratory applications. Models for production capacities and explosion-containment versions are also available.

Kason Corp.

Bag Filler is Designed for Stability in Sanitary Environments

The TWIN-CENTERPOST bulk bag filler has short posts for applications with little headroom. It is equipped with a manual fill-head height adjustment to accommodate smaller bag sizes, as well as pneumatically retractable bag hooks, an inflatable connector to seal the bag inlet spout, and a feed chute outlet port for dust-free air displacement during filling. Explosionproof NEMA 7/9-rated electrical system controls stabilize the bag for storage and shipment. The filler is available with a flexible screw conveyor, tubular cable conveyor, or dilute-phase pneumatic conveying system to deliver a variety of bulk materials from nearby or distant upstream sources. Options include: powered fill-head height adjustment; an inflator to expand the bag prior to filling; an automated vibratory densification/deareation system to stabilize the bag; and a powered or gravity roller conveyor. The dual-post frame maximizes the bag hooks’ strength and improves accessibility while simplifying construction and reducing cost. All product-contact surfaces are made of stainless steel, and the frame is available in either carbon steel with a durable industrial coating or in all-stainless steel construction that is finished to sanitary standards accepted by the U.S. Dept. of Agriculture (USDA). The conveyor system is also available with a dilute-phase pneumatic material delivery system integrated with upstream storage vessels or process equipment, terminating at a filter receiver above the filler. All system components are available constructed to industrial, food, dairy, and pharmaceutical standards.

Flexicon

Bulk Processing Feeder is Adaptable to Meet Application Requirements

The Model HFE-830-7-1/2-(3) vibratory feeder features an 8-in.-wide 30-in.-long flat trough and a hopper with a 3-ft3 capacity. The hopper supports and the entire trough frame are manufactured from Type 304 polished stainless steel and meet the U.S. Food and Drug Administration (FDA) food-grade standards. The feeder can easily handle either hot or cold materials. The custom-engineered, bulk-processing equipment and systems are suitable for use in a wide variety of dry processing industries from chemicals and food to aggregates and recycling. Typical applications include feeding to packaging, batch mixing, and drying processes.

Best Process Solutions, Inc.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.