Exhaust from automotive engines consists of hydrocarbons (HCs), carbon monoxide (CO), particulate matter (PM), and nitrogen oxides (NOx), most of which are converted to CO2, steam, and nitrogen (N2) by a catalytic converter. The catalytic converter is an integral part of the exhaust system for both gasoline and diesel vehicles, and it plays a crucial role in helping automobiles meet U.S. and European tailpipe emission standards. Since most emissions occur during the startup/warmup cycle (at converter temperatures below 200°C), reducing the temperature at which the catalyst can operate is one way to ensure vehicles meet those limits.

Pyrochem Catalyst Co. (PCC) is developing new catalyst materials to meet and exceed future standards. The critical challenge is to develop a catalyst that can convert 90% of exhaust pollutants at a temperature below 200°C, ideally below 150°C (known as the 150°C Challenge), with a performance lifetime that exceeds the equivalent of 150,000 miles of driving. The temperature at which there is 90% conversion of a pollutant is the catalyst’s T90.

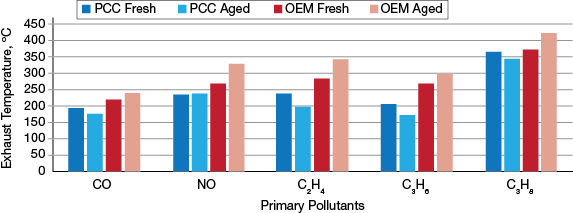

▲ Pyrochem Catalyst Co.’s PyroCat powdered catalyst and an original equipment manufacturer (OEM) catalyst were tested using the ACEC testing protocols to determine the temperature at which each catalyst converts 90% of each exhaust gas pollutant. (Lower temperatures are better.) The lower T90 of the aged PCC catalyst demonstrates its unparalleled resistance to high temperatures.

The automotive industry established the Advanced Combustion and Emission Control (ACEC) technical team to develop a set of testing protocols that can be used to compare the performance of candidate catalysts. The protocols specify the methods that are used to screen new catalyst materials. Catalysts are tested against simulated exhaust gas compositions, varying gas flowrates and temperature ramp rates, and a simulated aging process intended to create vehicle in-use conditions that promote metal sintering.

Current platinum (Pt)-, palladium (Pd)-, and rhodium (Rh)-based commercial catalysts cannot meet the T90 targets, either as fresh catalysts or after aging. These conventional catalysts are especially susceptible to sintering due to temperature spikes (up to 850°C) and activity losses associated with contaminants in the fuel and lubricant additives.

PCC’s proprietary PyroCat catalyst technology is a customizable pyrochlore-type crystal lattice (with the general formula A2B2O7), in which catalytically active metals and promoters can be isomorphically substituted in the crystal structure. This type of substitution allows the metals to be bonded into the structure, which imparts high-temperature stability and protection from catalyst poisoning. Specifically, PCC can substitute noble and non-noble metals and a wide range of promoters if they satisfy the necessary A-site to B-site ionic radii ratio requirement.

From the standpoint of catalyst design, these features are ideal for a novel automotive catalyst. Because the pyrochlore lattice can lock in metals like Pd and Rh, it is able to maintain a high metal dispersion and hence lower T90 values, even after aging. This has been confirmed by ACEC protocol testing and validated through onsite testing by an automotive equipment manufacturer and catalyst manufacturer.

PCC is continuing to develop new PyroCat formulations to meet the 150°C Challenge. The National Science Foundation (NSF) provided funding for the development and scale-up of a spray pyrolysis process (SPP) that is used for the rapid production of these pyrochlore automotive catalyst materials. The SPP consists of three steps: solution preparation, atomization of the solution, and thermal processing of the very fine droplets through a vertical furnace. The SPP, currently running as a pilot unit, can produce a wide range of pyrochlores, perovskites, and other mixed-metal oxides. What would normally require hours or days for conventional catalyst formulations, the SPP can accomplish in seconds.

PCC is seeking additional partners with an interest in testing its automotive catalysts and commercialization of its SPP.

This research was funded through the NSF Small Business Technology Transfer Research (STTR) Program.

This article was prepared by the National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.