Software

Software Simulates Plant Environment for Operator Training

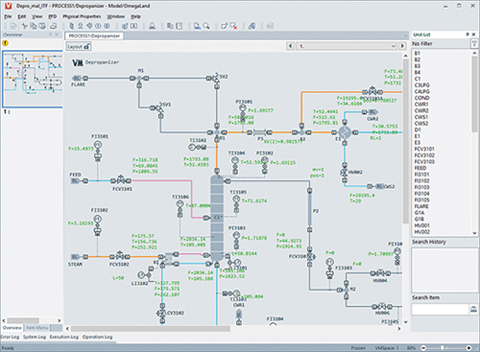

OmegaLand V3.1 dynamic simulation environment enables the construction of virtual plant models that can be used to train operators and study and verify new processes. The platform consists of the Visual Modeler dynamic simulator, as well as a variety of functional modules, including a graphic module for on-screen display of plant operations and a simulation control module. In the latest release, functional modules for training operators, studying process principles for plant operation, and solving equation models can be operated using the same integrated environment, enhancing efficiency. The new version allows the simulation to be paused, modified, and resumed at any time.

Omega

Simulation Tool Meets the Demands of a Modern Workforce

Simulation tools are often based on legacy architectures, operating systems, and user interfaces, but user expectations for scalability, ease of use, and modern technological tools are driving the need for a new approach. SimSci SimCentral manages the engineering of processes across the entire lifecycle, enabling streamlined process utility design, collaboration on process improvements, and simplified modeling. The updated user interface is more intuitive than other similar offerings, which helps to accelerate adoption, use, and time-to-value. Users in different time zones, departments, or organizations can work concurrently on the same model, which helps to support collaboration across a global business. Benefits include reduced project cost, accelerated process simulation and design, and an appealing user interface.

Schneider Electric

Feeder Control Platform Allows Customization

New features of the DISOCONT loss-in-weight feeder control platform include a favorites folder, customizable calibration sequences, detailed event message text, and HTML5 for online equipment monitoring. The favorites folder gives operators quick access to the parameters that are critical and unique to their individual process. Parameters that are rarely used can be hidden, minimizing the need to search through those that are irrelevant to the job at hand. A customizable calibration sequence guides users, and checkmarks indicate the status of each step in the sequence. The switch to HTML5 enhances compatibility with various web browsers and smartphones.

Schenck Process

Heat Transfer

Dry Bath Provides Temperature Control

The EchoTherm Model IC50 is a Peltier-driven, chilling/heating dry bath that controls sample temperatures. The unit includes a temperature probe that can be inserted directly into the sample or into the sample block. The probe senses the sample temperature or sample block temperature directly and sends that information to the temperature control unit to drive and control the temperature to the setpoint. A sensor in the heater plate allows users to set the plate temperature and use the probe to monitor the sample temperature. Temperatures can be controlled to ±0.1°C, and samples can be chilled or heated from –10.0°C to 110.0°C in assay plates, centrifuge tubes of all sizes, vials, test tubes, and most other sample containers.

Torrey Pines Scientific

Water Cooler Works with Passive Cooling Systems

Hybricool high-performance water coolers can be combined with passive cooling to create a complete cooling system. Combining active and passive cooling technologies enables extremely reliable cooling of field protection cabinets and shelters that house remote and mission-critical control and instrumentation equipment. The combined system can handle extreme climate conditions, as well as maintain continual operation in the event that one cooling method fails. For instance, if electrical power is lost, a passive natural-convection cooling system could continue operating until maintenance is performed. The water cooler is a closed-loop system with a compressor, condenser, throttle, and evaporator. The condenser is coated with a dust-protection system and does not require a filter. Versions suitable for hazardous areas are available.

Intertec Instruments

Instrumentation

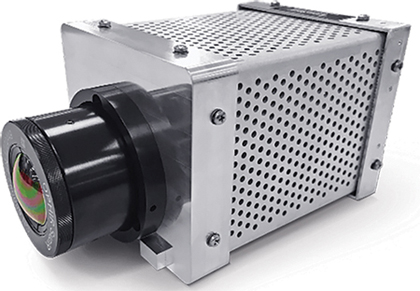

Thermal Imaging Camera Detects Process Upsets from a Distance

The MCL640 thermal imaging camera features 640×480 resolution imaging for long-wave infrared applications, enabling superior imaging and temperature measurement (±2°C). The thermal image resolution is four times that of previous models, providing enhanced temperature measurement accuracy. Users can select from a range of lens and environmental enclosure options for operation in a range of conditions. The vortex-cooled (VC) enclosure is a heavy-duty housing that can be used in refineries and other demanding applications. When paired with the telephoto lens, this improved camera can help detect process upsets and other problems sooner.

LumaSense Technologies

Flowmeters Enhance Measurement Quality and Device Accessibility

The Proline 300/500 family of smart Coriolis mass and electromagnetic flowmeters simplify installation, speed commissioning, and streamline operation and maintenance activities. The flowmeters combine Proline sensors with state-of-the-art transmitter technology, enabling simultaneous measurement of several variables. The Coriolis flow instrument can measure mass flow, volu-metric flow, density, concentration, viscosity, and temperature, while the electromagnetic flow instrument can measure volumetric flow, temperature, and conductivity. The flowmeter line offers a comprehensive range of signal outputs and protocols to ensure seamless integration into existing automation systems. Each device is checked using accredited and traceable calibration facilities.

Endress+Hauser

Engineering Services

Laboratory Performs Dust Collector Testing

This manufacturer of dust, mist, and fume collection equipment has doubled the size of its testing laboratory to include a climate controlled facility with a full-size dust-collection test rig. The new equipment is dedicated to testing in accordance with the ANSI/ASHRAE Standard 199-2016, which describes testing criteria for industrial pulse-cleaned dust collectors. The lab includes equipment for customer support and regulatory compliance testing, including an electron microscope capable of analyzing high-efficiency filtration media with nanofiber and polytetrafluoroethylene (PTFE) membrane coatings. Customers will benefit from simulations that mimic real-world conditions to evaluate the compliance and effectiveness of various filters.

Camfil APC

Laboratory Equipment

Automated Sample Storage System Aids Busy Technicians

The Verso automated sample storage system is suitable for medium to large storage needs at temperatures from ambient to –20°C. The modular design fits into compact laboratory spaces with ceilings as low a 7.10 ft (2.4 m). The Universal Picker accommodates 96-well tubes, 1-dram vials, and other types of vials and plates, eliminating the hassle associated with storing disparate labware separately. In addition to being convenient, this storage option provides a single, reliable method to securely document and track sample storage. Optional active thawing increases workflow efficiency by thawing samples before retrieval, and dual internal robotics and pickers increase throughput in large, customized installations. Walkaway automation allows users to attend to other tasks. Up to 1,500 tubes and 170 plates can be processed per hour.

Hamilton Co.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.