Big data can pave the way to greater business and operational insight. New approaches and technologies are poised to help you navigate your journey.

Much mystery surrounds big data. A 2014 survey by the ARC Advisory Group found that 38% of respondents did not understand what big data is or why they should care about it (1).

A common misconception is that big data is a thing. A more accurate metaphor is that big data enables a journey toward more-informed business and operational decisions.

Most companies have already embarked upon a big-data journey — whether they realize it or not. For many industrial companies, big data manifests itself as data from the Industrial Internet of Things (IIoT). The IIoT connects intelligent physical entities, such as sensors, devices, machines, assets, and products, to each other, Internet services, and applications. The IIoT is built upon current and emerging technologies, such as mobile and intelligent devices, wired and wireless networks, cloud computing, analytics, and visualization tools.

IIoT data have surpassed what most industry observers had anticipated, enabling data to arrive faster, from more data sources, and in greater volume. This has profoundly impacted analytics. The classic architecture used for business intelligence, operational intelligence, and analytics is no longer adequate. New analytics technologies are necessary, and they will need to be placed closer to the data source to be effective. This article introduces new analytics technologies and related supporting technologies, and presents some early big-data success stories.

What is big data?

ARC’s survey results are, in many ways, not surprising. Many industrial organizations do not understand big data.

A definition of big data established 20 years ago (2) stresses three Vs: volume (the amount of data managed), velocity (the rate of incoming data), and variety (the type of data). Sometimes veracity (the quality and accuracy of the incoming data) is also included in the definition.

Think about your current experience in terms of the original three Vs (volume, velocity, and variety) to determine whether your company is already on the big data journey.

Volume: Is the amount of data you manage growing at an accelerating rate?

Velocity: Is the rate at which data are generated accelerating? Are the people consuming the information gleaned from the data demanding more-timely insight?

Variety: Are the number and types of data sources you use for analytics growing rapidly?

If you answered yes to any of these questions, you are already dealing with big data; if you had two or more yes answers, you are further along the journey. A common thread through each question is growth (demand). It is not necessarily difficult to manage a large volume of data, but it is stressful to manage a body of data that is growing rapidly year after year.

A big-data journey must strike a balance between data supply (data management) and information demand (managers asking for different information or more-timely updates). The aim of any big data project must be to add business value — by enabling cost reductions, productivity gains, or revenue increases. Many older big data projects never reached the point where they were adding value. For example, it is not unusual to find projects based on plant historians that accumulate data for years without business or operational managers taking full advantage of the data through analytics.

The big data journey

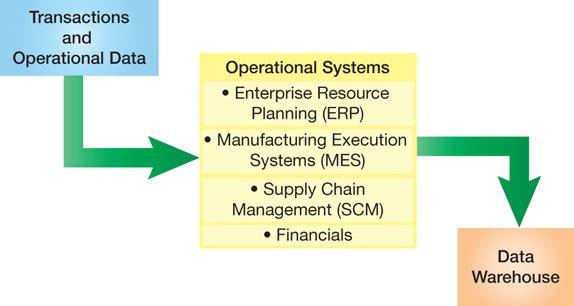

▲Figure 1. In a traditional business intelligence (BI) architecture, transactions and operational data are fed to operational systems that organize and manage the data, which are then stored in a data warehouse. The green arrows represent points where latency is introduced into the system.

Figure 1 presents a traditional business intelligence (BI)/analytics infrastructure of operational systems and a data warehouse. The operational systems may include enterprise resource planning (ERP) systems, which help manage financials, supply chain, manufacturing, operations, reporting, and human resources; manufacturing execution systems (MES), which track and document the transformation of raw materials to finished goods; supply chain management software; and financial and accounting software.

Delays and latency (green arrows) are built into this traditional system. It often takes time for all transactions to be entered into the operational systems. For example, hand-written maintenance records need to be transcribed into digital records so they can be analyzed and integrated with other data sources. There is usually a delay between capturing data in operational systems and...

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.