We all know that people, even highly trained people, occasionally make mistakes. It could be a manager making an ill-advised decision, an engineer making a poor design choice, an operator filling a vessel incorrectly, or a mechanic not completing a maintenance task correctly. Process safety pioneer Trevor Kletz observed that (1):

“Every accident is due to human error: someone, usually a manager, has to decide what to do; someone, usually a designer, has to decide how to do it; someone, usually an operator, has to do it. All of them can make errors but the operator is at the end of the chain and often gets all the blame. We should consider the people who have opportunities to prevent accidents by changing objectives and methods, as well as those who actually carry out operation.”

Some mistakes have minor consequences, while some can potentially lead to catastrophic incidents. The reality is that human error must be anticipated and appropriate systems and safeguards must be implemented to help ensure that errors do not lead to serious injuries or other consequences, especially if work tasks involve significant hazards.

For example, in an incident investigated by the U.S. Chemical Safety and Hazard Investigation Board (CSB) (2), an operator opened the bottom valve of an operating polymerization reactor, apparently bypassing an active pressure interlock, instead of opening the bottom valve of a nearby identical reactor that was being cleaned. A large release of flammable material from the reactor ignited, and the resulting explosion caused five fatalities and major damage to the facility. The CSB concluded, among other findings, that the facility “did not adequately address the potential for human error.”

What is the probability that a routine task will be completed correctly every day for a year? Using a typical error rate of 10–2 (i.e., a 99% success rate each time the task is done), the probability of correctly completing a task performed every day for a year can be estimated as:

Probability of no errors = (0.99)365 = 2.6%

Actual results will vary, of course, but given the low probability of error-free activity, planning for human error is essential. Some of the causes of error include (3):

- human fallibility, capability, and complacency

- training issues, including procedure quality and training effectiveness

- workplace environment, including accessibility of information and distractions

- poor familiarity with the work being done

- fitness-for-duty considerations, such as alcohol, drugs, stress, and fatigue

- urgency for completing a task quickly

- lack of risk recognition or sense of vulnerability.

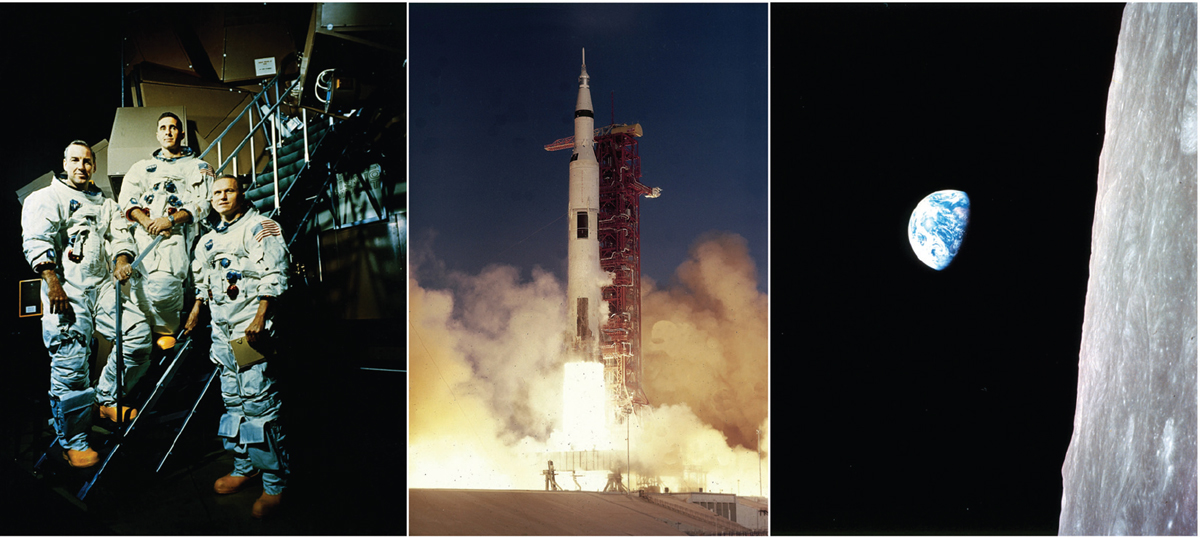

No one is infallible. Apollo 8 was the first crewed spacecraft to leave the earth’s orbit; risks were high and errors could be catastrophic (Figure 1) (4). A key development was the new computer to be used for navigation and return to earth. Software engineer Margaret Hamilton, though, was worried about how to prevent errors, such as entering the wrong information into the computer during flight. When playing with the software, Hamilton’s daughter had entered code P01 that caused the computer to crash, thinking it was on the launching pad, not in space. NASA decided that the astronauts were the most highly trained test pilots in the world and were unlikely to make such a mistake.

▲Figure 1. Photos from the Apollo 8 mission, the first crewed spacecraft to leave low Earth orbit. The crew — which included Frank Borman, James Lovell, and William Anders — were the first humans to witness and photograph an Earthrise (shown on the far right). Photos courtesy of NASA (nasa.gov).

But, of course, they did. A day and a half away from Earth, astronaut James Lovell was doing a star sighting. He wanted to enter “star number one” (S01) and by mistake he entered “program number one” (P01). The computer tried to reposition the command module, thinking the module was back on Earth. Lovell was able to correct the error (4), however, this example shows that even astronauts — among the most highly trained and capable people — make mistakes.

Strategies to reduce human error should include addressing potential causes and a focus on improved operational discipline, particularly for higher-risk activities. The Apollo 8 computer possibly could have been programmed, for example, to prevent entry of the wrong codes or to provide a warning if an inappropriate code had been entered. In the CSB incident, better differentiation in the appearance of the reactors may have prevented the mistake of working on the wrong reactor.

Everyone needs to know how to do their work tasks correctly and safely, do them the correct way without deviations or shortcuts, and anticipate and be prepared for what may be different or could go wrong and adjust accordingly (3). The goal is to have well-trained personnel following appropriate procedures, who also account for the existing work environment rather than having an unquestioning focus on strict adherence to procedure when circumstances are different or changing. Possible deviations and the correct ways to respond to them should be included in procedures and training to help mitigate any potential negative consequences.

Effective process design that includes multiple layers of safeguards based on appropriate risk evaluation and management practices must also be provided — just in case errors do occur, and they probably will.

Jim Klein, CCPSC, CPSA, is President at Process Safety Performance LLC (Email: jim.pspllc@gmail.com). He is a Fellow of both AIChE and CCPS.

- Kletz, T., “An Engineer’s View of Human Error,” 3rd Ed., CRC Press, Boca Raton, FL (2001).

- U.S. Chemical Safety Board, “Vinyl Chloride Monomer Explosion,” Report No. 2004-10-I-IL, CSB, Washington, DC (2007).

- Klein, J. A., and B. K. Vaughen, “Process Safety: Key Concepts and Practical Approaches,” CRC Press, Boca Raton, FL (2017).

- Nova, “Apollo’s Daring Mission,” WGBH Educational Foundation, https://www.youtube.com/watch?v=cdkV7m0BUNg (Dec. 26, 2018).

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.