In the U.S., 70% of consumed food passes through a cold chain, an uninterrupted series of temperature-controlled storage and distribution activities. Globally, maintaining these cold chains consumes one-sixth of all electricity generated and produces 30 billion metric tons of CO2 per year. Traditional vapor-compression heat pumps have low efficiencies, use refrigerants with a high global warming impact, and are unable to provide dynamic cooling capacity.

A new technology will dramatically change this picture by first complementing, and eventually replacing, vapor-compression cycles.

With support from the National Science Foundation (NSF), Colorado-based Rebound Technologies has developed IcePoint, a cooling system that incorporates a novel freeze-point suppression cycle.

Like all heat pumps, IcePoint changes the state of a refrigerant, which absorbs heat at a low temperature and then releases it at a higher temperature. However, instead of changing refrigerant pressure, the freeze-point suppression cycle alters the refrigerant’s chemical composition to change its freezing point.

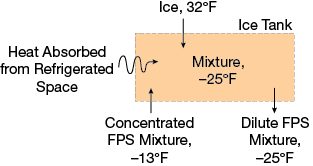

▲Figure 1. The freeze-point suppression cycle uses water as a refrigerant in the presence of a freeze-point suppressant (FPS).

The freeze-point suppression cycle uses water as a refrigerant in the presence of a freeze-point suppressant (FPS) (Figure 1). As heat is absorbed from the refrigerated space, refrigerant, in the form of ice, melts and dilutes the FPS-water mixture. The mixture, now with a lower FPS concentration, is separated into pure water and concentrated FPS. The water is then frozen, which releases heat. Next, the ice and the concentrated FPS are mixed, completing the cycle.

▲Figure 2. Paramount to the freeze-point suppression cycle is the spontaneous endothermic effect that occurs when ice is mixed with a concentrated FPS in the ice tank.

Key to the freeze-point suppression cycle is the spontaneous endothermic effect that occurs when ice is mixed with a concentrated FPS. This effect occurs at steady conditions inside a tank where ice and concentrated mixture are added while dilute mixture is removed (Figure 2). The sensible heat added to the tank by the ice, incoming concentrated mixture, and incoming heat from the refrigerated space are all balanced by the high latent heat of fusion of the ice.

IcePoint can be integrated into existing industrial freezer systems to provide dynamic capacity (28–140 tons of refrigeration) and superior efficiency. These characteristics can dramatically improve energy utilization and food supply through the entire global cold chain.

The FPS cycle offers several key benefits over traditional vapor-compression cycles, including: it uses a natural refrigerant with no global warming potential (GWP); it provides dynamic cooling, enabled by the use of storable refrigerants throughout the cycle; and its highly thermodynamically efficient nanofiltration separation process increases overall efficiency by 35%. Recent advances in precision controls, membranes, membrane modules and pressure recovery devices drive FPS cycle innovation.

Lineage Logistics, the second-largest cold storage company in the world, installed the first IcePoint pilot unit in March 2018. Pilot data demonstrated an adjusted coefficient of performance (COP, a ratio of useful cooling provided to work required) of 3.12±0.09 at a temperature as low as –22°F, compared to a typical COP of 2.0 for conventional equipment.

“This is among the most significant developments in industrial refrigeration that we’ve seen,” says Alex Woolf, Principal Data Scientist at Lineage. “It provides dynamic cooling capacity, while avoiding peak energy. No other cooling technology offers such flexibility, and IcePoint accomplishes it with a huge COP improvement.” Lineage anticipates a commercial unit will provide $275,000 annually in increased earnings, 80% of which are due to increased throughput of product frozen at their facilities.

IcePoint allows companies to perfectly match their cooling demand throughout the day. “IcePoint offers a promising alternative to vapor compression that will yield a significant boost in earnings for food processors,” says Russell Muren, Rebound Technologies CTO and inventor of the cycle.

This technology was funded through the NSF Small Business Innovation Research Program.

This article was prepared by the National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.