Dynamic matrix control has long been a part of the process control engineer’s toolbox, but the technology remains widely unknown among other engineering disciplines despite its benefits to manufacturing processes.

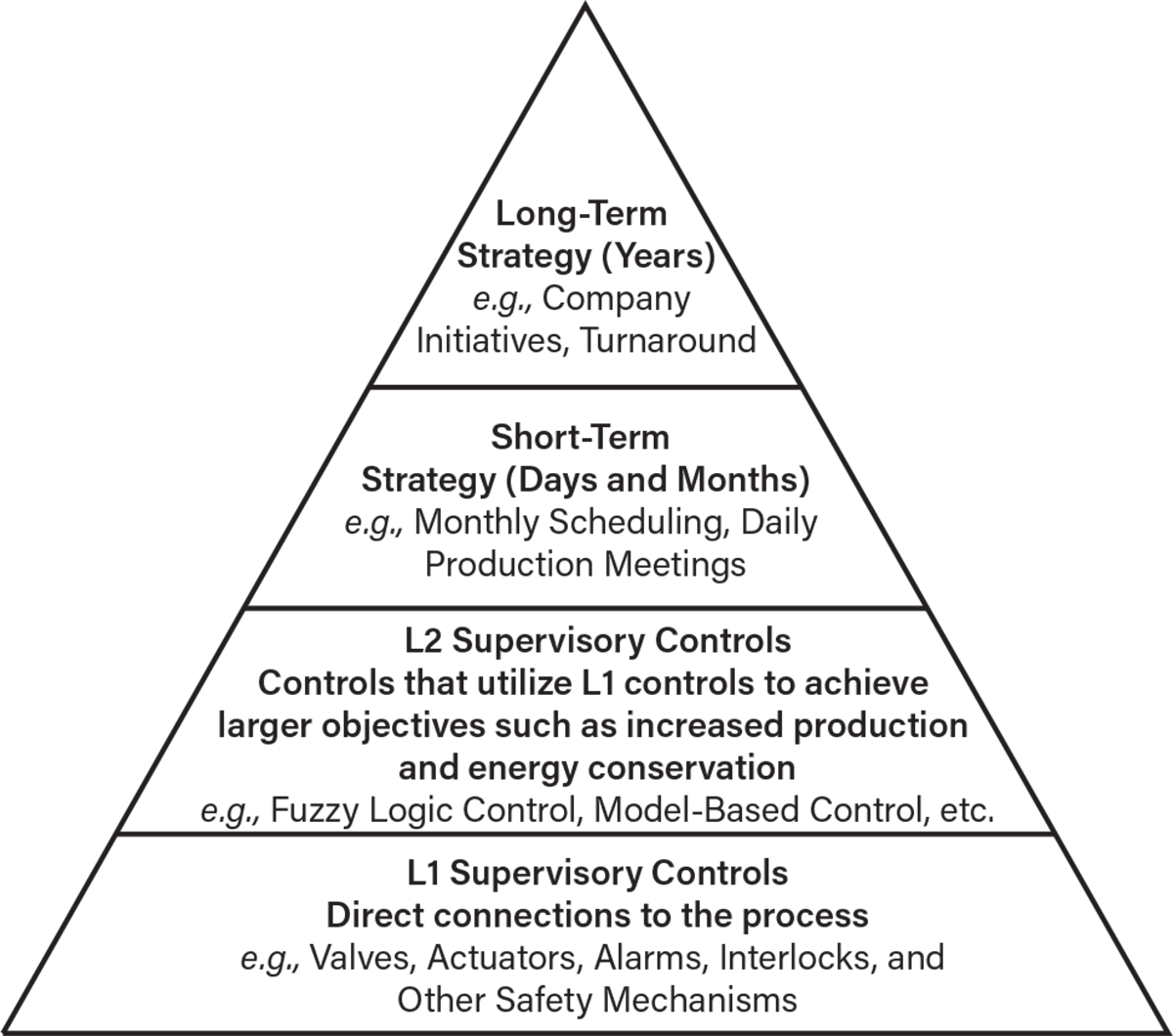

Dynamic matrix control (DMC) is a type of advanced process control. First introduced in the 1980s by Cutler and Ramaker (1), DMC is a specific branch of process control that is nestled within the myriad levels of controls necessary to keep an advanced process plant running (Figure 1).

▲Figure 1. The four different levels of industrial process control — Level 1 (L1), Level 2 (L2), short-term strategy, and long-term strategy — require a solid L1 foundation with accurate data acquisition, effective process instrumentation, and robust safety mechanisms upon which an L2 supervisory system like dynamic matrix control (DMC) can be built (2). This figure is similar to the American National Standards Institute/International Society of Automation (ANSI/ISA)-95 standard and the International Electrotechnical Commission (IEC)-62264 standard, but it has been modified to highlight the difference between L1 and L2 controls.

Level 1 (L1) controls are those that are directly linked to the process. Sensors measure process variables and pass the readings up to the control level. The control level can consist of programmable logic controllers (PLCs), a distributed control system (DCS), or a personal computer system (PCS). The control level processes the sensor readings and sends commands out to the actuators. Controllers at this level are also known as single-input single-output (SISO) or multi-input single-output (MISO) controllers (2).

Level 2 (L2) controls consist of supervisory controls that optimize and improve production. Model-based control (MBC) is one of the many types of controls that exist at this level. Within the field of model-based control, there exists internal model control (IMC), model predictive control (MPC), and process model-based control (PMBC). DMC is a type of MPC (2).

There are two major principles behind MPC. The first is that any input behavior can be represented as a sequence of steps, and the output of a linear process can be represented as the cumulative effects of those steps. Together, the input steps and the output responses form a model. The second is that once the model is identified, a desired behavior for a specific variable can be expressed as a target vector, and the moves required to reach that target can be calculated from the model inverse (2). Moves to reach the target can be made over a chosen time period. This time period is called the time to steady state and is usually more than an hour.

The “matrix” portion of DMC comes from the matrix of models from different inputs and outputs that are part of a unit. In the past, linearity of the process model was of high importance. New technologies and techniques are changing this need for linearity (3). This article features a few examples of how nonlinear systems can be integrated into DMC.

DMC has been proven to improve unit operations by using manipulated variables to control a process within chosen constraints and, therefore, DMC is also referred to as multiple-input multiple-output (MIMO) control (1). A few examples of how DMC can be used include:

- Increasing the feed rate to a unit depending on multiple unit constraints such as tower pressure and steam valve outputs. When possible, DMC will manipulate pressure or temperature controllers to control the tower pressure valve and steam valve within limits. Feed will only be cut once the pressure and temperature controllers can no longer handle the constraints. This allows for maximum optimization.

- Achieving the dual objectives of minimizing steam use and varying steam, feed, and reflux on a distillation column to target a certain product specification. If the steam valve on the column is saturated, DMC can utilize either feed or reflux to relieve the steam valve and reach product specification.

- Regulating an extractor’s bottoms temperature, taking into account multiple variables such as an upstream flowrate, a feed preheater, and a recycle flow. DMC can use any combination of these variables to regulate the bottoms temperature. If the feed preheater is out of service, then the recycle flow can take more responsibility in regulating the bottoms temperature.

- Maintaining a certain isobutane-to-olefins ratio for an alkylation reactor. In alkylate reactors, the system must produce alkylate within a specific Reid vapor pressure (RVP) limit. DMC normally maintains a certain isobutane-to-olefins ratio to meet the RVP limit while also watching reactor limitations.

- Controlling the differential temperature across a reactor via a reactor recycle loop while using the temperature differential to achieve a desired conversion in the reactor. Temperature is related to conversion and can be measured easily. Conversion must be calculated and can vary in accuracy, depending on the type of measurement used.

- Estimating the production during nonlinear batch processes. If different reactors are used for a process, a dynamic equation can be created to estimate the production depending on the reactor’s characteristics. This equation could then be used to manage feed, catalyst, or other inputs by integrating them into a DMC system.

From the examples above, it is clear that an advantage of L2 over L1 control is that it can manage multiple objectives and constraints at the same time. Similar to how a house should be built on a strong foundation, an L2 control scheme, such as a DMC, will only be successful if the L1 controls are in good shape.

Since its introduction in the 1980s, DMC has evolved in many exciting ways. When the technology was first introduced, only a few constraints around one piece of equipment could be managed in one controller. Computing power and control system improvements have contributed to making update times faster and increasing the span of control. Now, DMC matrices can be designed to control multiple units. Despite these improvements, for many engineers outside of process control, DMC can be a mysterious and murky technology.

This article describes the major steps in DMC development. This is not intended to be a mathematically detailed discussion of matrix control but instead an introduction to the different facets of DMC development. This article uses a simple distillation system to illustrate different aspects of the DMC development process. The DMC development process varies from engineer to engineer and process to process; however, the steps that follow are from the author’s extensive experience in developing DMCs across industries...

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.