The manufacturing sector faces mounting pressure to meet growing demands for materials and reduce environmental harm. Global materials and chemicals production accounts for ~30% of all carbon dioxide (CO2) emissions, yet demand for these essential goods is projected to quadruple by 2050 from a 2010 baseline.

The production of cellulose, a material widely used in textiles, packaging, and paper, exemplifies this challenge. Three tons of wood are required to produce one ton of industrial-grade cellulose, resulting in the logging of three billion trees per year — nearly half of which come from ancient and endangered forests.

With Phase I and Phase II funding from the U.S. National Science Foundation (NSF) Small Business Innovation Research (SBIR) program, Rubi Laboratories has developed a cell-free enzymatic biocatalysis platform that converts CO2 into industrial-grade cellulose, offering a first-of-its-kind sustainable alternative to large-scale forestry-based cellulose production.

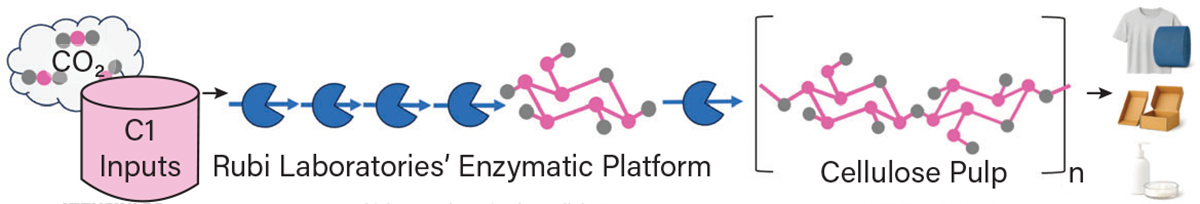

The Rubi platform uses a specialized multi-enzyme cascade to convert single-carbon (C1) material, including CO2 and CO2-derived feedstocks such as methanol, directly into cellulose polymers without relying on living cells. The biocatalytic system harnesses enzymes outside of cells’ biochemical constraints. Numerous purified enzymes operate together in a chemical reactor to efficiently transform C1 inputs into complex multi-carbon products. Rubi partners with industrial enzyme manufacturers to produce their specialized enzymes at scale.

▲ Rubi Laboratories’ first-of-its-kind biocatalysis platform uses a multi-enzyme cascade to convert C1 feedstocks like CO2 and methanol into complex carbon products like cellulose.

The enzymatic process operates in two phases. First, single-carbon feedstocks sourced from industrial CO2 emissions or CO2-derived building blocks are reacted to transform C1 molecules into sugar monomers. Next, these monomers are polymerized to produce insoluble cellulose. These polymers meet the purity and performance specifications of conventional textile-grade wood pulp.

In Phase I of its NSF SBIR project, Rubi demonstrated its C1-to-cellulose biocatalysis process. The demonstration showed that purified enzymes functioned effectively outside of cells and that the quality of the cellulose matched industry benchmarks. Now, in Phase II, Rubi is scaling the platform toward commercialization, including enzyme production optimization and scaled process development.

Fermentation-based biomanufacturing has enabled some emerging alternatives for biopolymer and chemicals production, but due to the fundamental constraints of living cells — including the need to keep cells alive, minimize metabolic burden, and avoid product toxicity — they often suffer from low conversion yields, high energy requirements, and high capital costs. Compared to fermentation, Rubi’s cell-free technology enables higher substrate concentrations, faster reaction rates, higher volumetric productivity, and dramatically improved conversion efficiency. By decoupling enzymatic processes from cellular constraints, Rubi’s platform allows processes to be optimized for catalytic efficiency and productivity.

Rubi has achieved yields of cellulose synthesis above 95% — a threefold improvement over typical precision fermentation or traditional wood pulp yields. Rubi also reduced energy consumption by 50–90%.

Compared to wood pulp production, early lifecycle assessments of Rubi’s process show significant potential environmental benefits, including a more than 50% reduction in CO2 emissions, a 60% reduction in water consumption, and a 98% reduction in land use, mitigating the impact of deforestation.

Rubi has also improved the overall productivity of its platform, reducing the cost of enzymes. Now, the company is advancing pilot collaborations with leading apparel companies, including H&M, GANNI, Walmart, and Patagonia. Process throughput has been increased by orders of magnitude without compromising cellulose yields or quality. Rubi aims for enzyme lifetimes on par with current industrial processes, which range from months to a year.

Rubi’s technology has implications far beyond textiles. With the broader vision of creating a new manufacturing paradigm across all key carbon-based chemicals and materials, Rubi plans to expand its carbon-to-materials platform into personal care, packaging, chemicals, food, and building materials, offering a path to decarbonizing diverse sectors.

This technology was funded through the NSF Small Business Innovation Research (SBIR) Program.

This article was prepared by the U.S. National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.