Sections

Many academic lab safety programs have room for improvement. This article demonstrates how to implement certain industrial lab safety practices in an academic environment.

Research laboratories in academic institutions have similar responsibilities to those of the broader chemical industry — to create and maintain a safe working environment for their employees, students, faculty, and staff. Over the past few decades, safety practices in the chemical industry have improved and innovations such as incident reporting, data tracking, and benchmarking have contributed to a reduction in the number of serious safety incidents and fatalities. Conversely, academic research labs, which experience fewer serious incidents and fatalities, have generally lagged in their safety innovation.

Recent severe accidents in research labs have raised the profile of safety practices in academia. Emerging research suggests that the number of safety incidents occurring in academic labs is being underreported; such research has also raised questions about safety culture (1). Based on these findings, there appears to be a divergence in the approach to safety between academia and industry. Assuming such a divergence exists, we asked ourselves what would this mean for our own safety program at the Univ. of Virginia (UVA). This article reviews the aforementioned divergence, reflects on the status of our own safety program, and shares perspectives about our journey of continuous improvement in our laboratory safety practices.

Character of academic research

Perceptions about lab safety and risk can differ between academia and industry, largely influenced by differences in the character of research conducted in each institute. One of the most noticeable differences is scale. Experimental scale is much smaller in academic labs, with experimentation rarely exceeding benchtop. Small-scale experimentation can lead some students and staff to assume the threat of certain activities or hazards is unsubstantial, which might reduce the diligence applied to risk management.

In addition to differences in scale, the way in which academic experimentation is performed might also influence perceptions of safety. Most academic research is performed intermittently and with fewer people, which has the effect of creating fewer serious accidents than in industry. The academic lab workforce, which often consists of graduate students and postdocs, is also unique. Academic researchers are typically transient, cycling in and out of a lab dependent upon their degree or project schedule. Academic researchers often complete their work independently, whereas industrial research activities are often performed in the presence of others.

Due to the small-scale and intermittent nature of academic research, some academic institutes might never experience a serious safety incident. Without evidence of incidents or accidents, the institution will have little impetus to initiate review or improvement of existing safety practices and processes. Without continuous improvement and in the absence of incidents, individuals and institutions are at risk of becoming complacent, and they may assume that risks are being managed effectively. Moreover, a transient workforce can impair the transfer of important safety knowhow between new and experienced researchers. Without an experienced core of researchers or adequate onboarding of new employees, it can be difficult to sustain institutional knowledge about safe lab practices. These differences provide perspective about why and how risk perception and risk management strategies differ from that of industry.

Safety incidents in academia

Despite the small scale and intermittent nature of academic research, recent incidents provide evidence that major accidents can and do occur in academic research settings. Between 2001 and 2018, the U.S. Chemical Safety and Hazard Investigation Board (CSB) reported 120 academic research laboratory accidents (2). Accidents ranged from evacuations (n = 87) to serious injuries (n = 99). Three serious incidents at Texas Tech Univ. (3), Univ. of California, Los Angeles (UCLA), and Yale Univ. (4) have featured prominently in the academic safety community and safety literature. Moreover, the occurrence of these severe and rare events raised the prominence of academic laboratory safety, generating new interest in safety research and a greater number of investigations.

The CSB’s reporting of 120 academic research laboratory incidents over a 17-year period speaks to the rarity of safety incidents in labs; alternatively, it may point to a more troubling case of underreporting. In a recent study about academic laboratory safety, 2,400 scientists were asked about laboratory accidents at their institution. Focused primarily on chemistry and biology labs, 30% of respondents reported having witnessed a lab injury severe enough to warrant attention from a medical professional, with 15% of respondents reporting sustaining at least one injury themselves (1). Of those respondents who indicated they were involved in an accident or injury, 25–38% did not report the event to the principal investigator (PI). This evidence suggests that the prevalence of laboratory accidents in academia is being underreported.

Lab accidents are not limited to research settings alone. An Iowa State Univ. report suggests that 18% of the total incidents reported at the university from 2001 to 2014 occurred in chemistry teaching and research labs, and that 12% of those surveyed sustained an injury during undergraduate instruction. In addition, close calls involving no injuries are anecdotally far more common than accidents involving injuries, but these too are rarely reported unless the property damage is severe.

Industry uses incident and near-miss reporting data to benchmark safety performance, support real-time tracking of safety initiatives, and inform updating or bolstering of current safety measures. In academia, incident underreporting is a significant problem (1), and without supporting safety data, it is difficult to track and assess safety performance. Without data to inform change, institutes might wait until a severe incident occurs before taking action to review and evaluate their safety program.

A comprehensive review conducted by the American Chemical Society (ACS) (5) investigated underreporting of safety incidents and concluded that failings within the safety culture of labs and institutions were the root cause of severe safety incidents. Specifically, the report points to poor planning and risk assessment of new experiments, inadequate communication about safety hazards to and among researchers, and limited oversight by PIs as being the three factors that most contributed to the occurrence of safety incidents in academic labs.

These factors have been identified elsewhere in the literature (6). A study that compared behavioral differences between researchers in academic and industrial labs showed striking differences in how individuals from each institute used safety procedures. Industry researchers were more likely to use risk assessment methods before performing experiments than those in academia (43% vs. 18%, respectively). Self-reported personal protective equipment (PPE) usage (e.g., use of eye protection) was higher in industry (83%) than in academia (61%). Researchers in both industrial and academic labs shared similar levels of safety training and a common belief that personal risks were lower than the risk assumed by the institution. Interestingly, an individual’s perception of risk will influence their PPE compliance. In academic settings, PPE compliance correlated positively when an employee’s behavior was monitored by lab safety officers or PIs. Labs with active PIs or safety officers reported a lower number of safety incidents and accidents, yet PPE compliance data would suggest that the active involvement of PIs or lab supervisors in monitoring behavior in the lab is low (7).

Underreporting, poor compliance, and a lack of safety culture are believed to be contributing to poor safety performance in academic institutions. Without understanding the true number of incidents and significant near misses that occur in academic research labs each year, it is difficult to assess the quality and effectiveness of existing safety controls. Therefore, it is not surprising that the detailed review and overhaul of academic safety programs are often initiated only after a significant safety event has occurred. However, reactivity is the antithesis of risk management.

Safety culture in academia

The true measure of an organization’s commitment to safety can often be assessed by its safety culture. The Center for Chemical Process Safety (CCPS) describes safety culture as “how the organization behaves when no one is watching” (8). Safety culture is largely a function of the values, actions, and behaviors of an organization’s employees and how these values, actions, and behaviors are communicated (or shared) throughout the organization. Industrial organizations have made considerable strides to improve their safety culture, however, the concept of safety culture is much less developed in academic research settings (5).

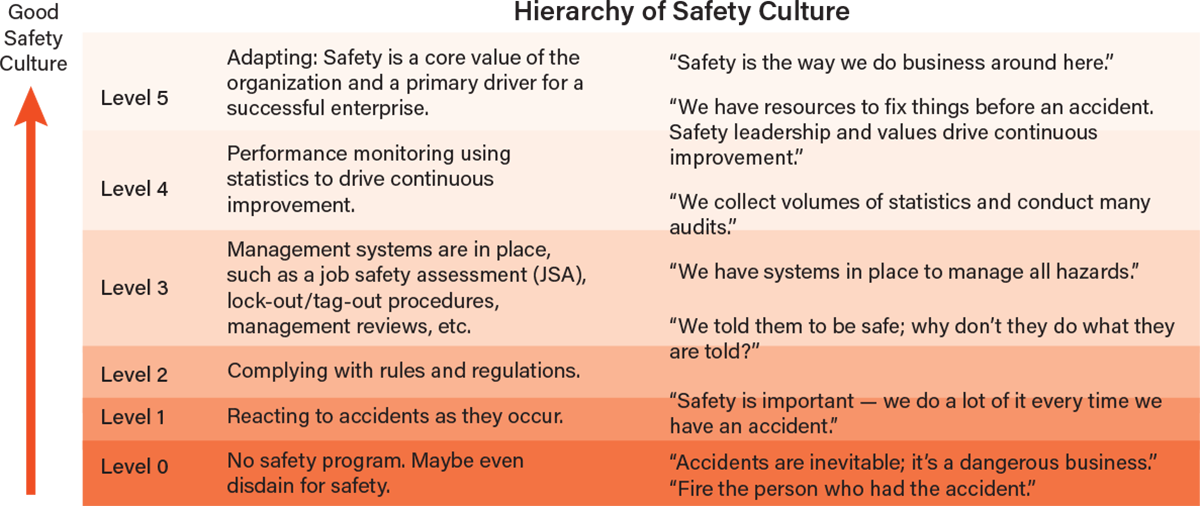

One useful model to characterize safety culture is the hierarchy model (Figure 1) (9). In this model, the maturity of an organization’s safety culture is defined by levels ranging from “No safety program” (Level 0) to “Adapting” (Level 5), the highest level of maturity, where safety is considered a core value in an organization. Each level builds on the other, therefore, an organization must first address and adopt the defining characteristics of the previous level before advancing to the next (10).

▲Figure 1. In the hierarchy of safety culture model, shown here, the highest level of safety maturity (Level 5) represents an organization where safety is considered a core value. Source: Adapted from (9).

Poor safety culture has been reported as the root cause of numerous serious academic laboratory accidents (6). The American Chemical Society (ACS) studied safety culture in academic labs and suggested that a strong safety culture in academia should include:

- an established culture set by leadership

- continual building of safety knowledge

- solid safety awareness among individuals

- learning from incidents

- active and collaborative safety committees

- promotion and communication of safety

- funding for safety programs and supplies.

Safety values and priorities must be developed at the top of the organization (4) and then communicated among all those involved. In academia, the messaging begins with leadership at the top (i.e., presidents, provosts, and deans), and cascades down through the administrative hierarchy. Supervisors and PIs are responsible for safety within their labs and thus have the most influence on individual safety behaviors and the overall effectiveness of a safety program (7). Students and researchers working in the labs who manage lab risks on a day-to-day basis will also carry disproportionate influence on safety culture.

Maintaining uninterrupted safety communication throughout the organization is key to ensuring that safety is prioritized, valued, and on-the-mind because this level of engagement influences individual behavior and thus organizational culture. Any lapse in communication or break in the communication chain might signal that safety is no longer an institutional priority, potentially leading to poor safety behaviors.

Our journey: Univ. of Virginia Dept. of Chemical Engineering

Maintenance of a successful safety program requires time, effort, and resources. Program improvement, however, requires the additional organizational commitment to reflect and self-examine. At UVA, we initiated a safety program more than 30 years ago at the urging of our Departmental Industrial Advisory Board. Change was initiated by an incident involving a graduate student working alone with toxic chemicals in a research laboratory that had the potential to be serious. We (at the time) took action to improve upon the existing safety program and implemented several activities and norms that addressed gaps in safety protocols, many of which are still used today.

- Department safety manual. A common manual was developed that included detailed information about the hazards, remediation actions, and sources for help specific to the research needs of the department. The manual complemented existing safety documents and procedures used by the university’s environmental, health, and safety (EH&S) department and was reviewed regularly (and updated if necessary).

- Annual safety seminar. A mandatory safety seminar was instituted for all ChE faculty, staff, and students, and was used to kick-off each academic year. The seminar addressed common issues about hazard management, waste handling, and recent inspection findings.

- Safety committee. A safety committee was created whose responsibilities were to maintain and update the safety manual, organize safety seminars, conduct periodic lab inspections, investigate incidents and serious near misses, and provide a single point of contact for those who wanted more information about safety. The committee was faculty-led and included participation from graduate students.

- Safety award. A prize of $1,000, sponsored by DuPont, was awarded each year to a student (graduate or undergraduate) in recognition of their efforts to make safety-related improvements or changes to laboratory practices.

- Professional development. Funding for faculty to participate in AIChE-led safety workshops was made available by the department.

Over time, as faculty sponsors retired or moved on and were replaced by new faculty with different priorities, the impetus to continually update and evolve our safety program lessened. Despite not experiencing a major safety incident since initiating our program (30 years ago), we recognized that our once robust and proactive safety program was no longer fit-for-purpose and required a refresh.

How did we initiate improvement?

Motivation to review our approach to safety emerged from a belief that safety should evolve to meet the changing needs of the department. Growth, both in terms of faculty numbers and graduate researchers, has been the greatest factor contributing to this change. Over the past seven years, the department has grown from 8 to more than 20 faculty members, and the number of graduate students has increased nearly 2.5-fold. Research activities have also diversified and now include work in the biotechnology, materials, environmental, and energy sectors. Risk profiles differ for each new research area and thus require specific strategies for management. By undertaking a review of our safety practices, we were able to take stock of the risks currently being managed in the department and understand how a changing research portfolio is being served by the existing safety protocols.

We devised a process for reviewing our safety practices:

- Identify opportunities to improve

- Develop a plan of action

- Implement solutions

- Evaluate performance.

We began our self-assessment with a review of current safety practices and perceptions, which we benchmarked using a survey of the graduate research students currently working in the labs. The survey was designed to address specific safety topics (Table 1) and asked questions about student perceptions of safe lab practices and safety culture within specific laboratories.

| Table 1. These thematic areas and example rating statements were used in the survey to benchmark safety perceptions in the department. | |

| Thematic Areas | Examples of Rating Statements |

| Management Commitment |

- I feel comfortable asking for help or oversight when planning my work or setting up new experiments |

| Safety as a Priority |

- I am provided the appropriate personal protective equipment in my work |

| Communication and Training |

- I receive adequate safety training to assure a safe work environment in the lab - There is good communication about safety issues that affect me |

| Supportive Environment |

- When I observe a potential safety issue, I feel comfortable raising or reporting safety issues to faculty and others |

| Open-Ended Questions About Practice |

- Please provide one example of good lab safety behavior that you have observed in your lab - Please provide one example where you believe that lab safety could be improved |

| Perception of Safety Culture |

- Reflect on the status of the safety culture in your lab, and describe where you think it stands currently |

Respondents used a seven-point Likert scale (e.g., strongly agree, strongly disagree) to respond to statements related to the six thematic areas. Two open-ended questions were used to gather qualitative information about good safety practices ongoing within labs and areas for improvement. A final question asked respondents to reflect on their perception of the department’s safety culture and rate their perception against the hierarchy of safety culture (see Figure 1).

The survey was completed by 70% of our graduate researchers and the results revealed several examples of good practice ongoing within the department, as well as some opportunities for improvement. Some examples of good practice in the department included:

- excellent understanding of safety requirements and expectations

- widespread use of PPE

- comfortability in asking for help, and intervening if something seemed unsafe

- openness for reporting issues.

From our findings, we identified multiple opportunities for improvement, including a need for improved sharing of safety best practices between labs and across the department, codified roles and responsibilities, and streamlined mechanisms for incident and near-miss reporting.

Responses about individuals’ perception of the department’s safety culture ranged from a Level 2 (Compliance) to a Level 5 (Adaptive), which suggests that our labs are at different stages of the safety journey.

Where are we heading?

Our safety program continues to rely on the safety initiatives developed by the department some 30 years ago. Using information from our self-assessment, we targeted three areas of improvement (e.g., knowledge sharing, roles and responsibilities, and reporting) that we believed would benefit our program by promoting safety conversations within the department and highlighting the importance and value of safe research practices. The following examples describe small actions we have taken that we believe complement and strengthen our safety program.

- Safety moments. Safety moments are brief presentations that highlight a specific safety topic. These take the format of a one- or two-slide presentation at the start of each department seminar. The goal of the safety moment is to stimulate discussions about safety incidents and raise the prospect of changing attitudes and behaviors. Safety moments are routine in industrial settings and are beginning to gain adoption in academia (11). We piloted safety moments during our summer graduate seminar series in 2019, with volunteers beginning each seminar with a two-minute overview of a laboratory safety incident, action, or procedure.

All departmental seminars now begin with a safety moment and the results have been positive. We have observed that individuals are more willing to speak up or ask questions about safety, are more aware of potential hazards, and are more interested in sharing information and cultivating safety dialogue across the department.

- Refresh of the safety manual. Emphasis was placed on revising the safety manual to include management of new hazards (e.g., lasers, infectious materials, and procedures for handling liquid nitrogen), in response to the department’s rapid growth and the changing character of ongoing research. The revision process required interaction with each faculty member to understand their unique risk profiles as well as interaction with the university’s EH&S department to understand how our procedures integrated with the institute’s. Constant communication with the department chair ensured continual faculty support. We improved accessibility by digitalizing the manual and creating a new departmental safety webpage to host it (https://engineering.virginia.edu/departments/chemical-engineering/che-safety).

Our existing manual was adequate in many respects but did not fully reflect the ongoing research activities in the department. More importantly, the manual was not readily accessible, and by creating a digital online version we democratized accessibility.

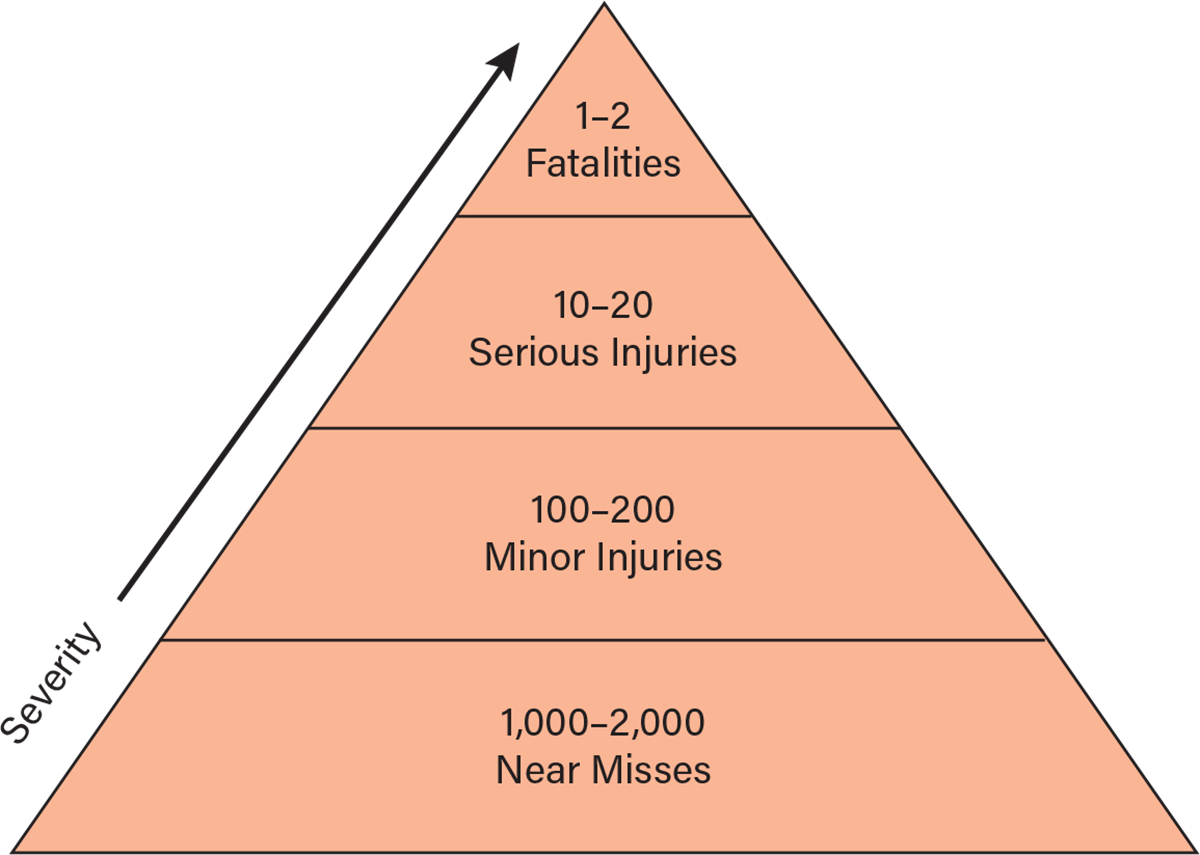

- Enhanced incident and near-miss reporting. In the two years prior, we received around three incident/near-miss reports a year. Safety performance relies on data to measure and monitor effectiveness, so we sought to improve data collection by communicating its value to the department and stressing that no matter how minor an incident or near miss, everything must be reported. Both safety accidents and near misses can share similar root causes and the severity of an event might be influenced by only the slightest change in circumstance. By reporting all minor incidents and analyzing their root causes, we are increasing the number of opportunities to learn about our safety performance and this should help us eliminate the potential for serious injury or incident (Figure 2). An incident reporting button was added to our safety website to facilitate rapid reporting, and QR codes were distributed to labs to further expedite access. Incidents are aggregated weekly, and investigations are undertaken proportional to severity.

▲Figure 2. Shown here as an example, the safety triangle provides perspective about the number of recorded near misses compared to the number of serious incidents that might occur. Organizations that collect near-miss data substantially increase their opportunity to learn about and prevent safety incidents. Source: Adapted from (9).

We now receive reports of ~3–5 incidents and near misses per month, which we consider a major improvement. Reported incidents are also being shared by students as part of our weekly safety moments.

- Industrial expertise and education. The hiring of a retired industry executive with over 30 years of experience managing highly hazardous operations in the oil and gas sector provided the motivation to initiate these activities. This expertise has been instrumental in adapting and piloting several industrial safety practices in an academic setting (e.g., safety moments, incident reporting), as well as urging us to stress-test some of our own assumptions about safety. Moreover, this expert developed a core curriculum undergraduate course on process safety, as well as an elective course on process safety fundamentals.

Change requires energy and ownership. Bringing in outside expertise to lead our improvements provided both a wealth and depth of industrial knowledge and the energy to carry out our initiatives.

- Annual safety seminar. We begin each academic year with a mandatory safety seminar for all ChE faculty, staff, and students. Similar to previous years, the seminar addresses common issues about hazard management, waste handling, and recent inspection findings. Unlike previous years, we adapted the seminar to focus on facilitating improved knowledge sharing and reporting by reflecting on recent incidents reported during EH&S inspections and safety committee inspections.

The safety seminar provides opportunity for faculty, staff, and students to ask questions, to share personal safety insights, and to reset our safety culture.

Last thoughts

We embrace the view that improving safety performance is a journey, not a destination (12), and that improvement requires ownership and continual reflection and assessment. Our own continuous improvement was initiated by energetic leadership and began with a benchmarking exercise that we have used to measure performance improvements. Each improvement that we implement adds a layer of protection, and it is the presence of these defenses that creates a safe work environment that minimizes risk. Along our journey, we have learned that:

- There is no substitute for data — completing surveys, collecting near-miss reports, and having conversations with researchers and faculty are all instrumental for influencing change.

- Even the smallest of changes can have a large impact on safety culture (e.g., beginning seminars with safety moments).

- Industrial best practices have use in a university setting (e.g., safety moments, incident reporting), and can be integrated into the day-to-day operation of a ChE department.

Wherever your institute sits on the spectrum of safety performance and culture, there will always be opportunity for improvement. In our case, understanding and translating industrial lab safety practices into the academic environment has shown benefits.

Literature Cited

- Ménard, A. D., and J. F. Trant, “A Review and Critique of Academic Lab Safety Research,” Nature Chemistry, 12 (1), pp. 17–25 (2020).

- U.S. Chemical Safety and Hazard Investigation Board, “Laboratory Incidents January 2001 – July 2018,” https://www.csb.gov/assets/1/6/csb_laboratory_incident_data.pdf (2018).

- U.S. Chemical Safety and Hazard Investigation Board, “Texas Tech University Laboratory Explosion. No. 2010-05-I-TX,” https://www.csb.gov/texas-tech-university-chemistry-lab-explosion (2011).

- Van Noorden, R., “A Death in the Lab,” Nature, 472, pp. 270–271 (2011).

- American Chemical Society, “Creating Safety Cultures in Academic Institutions: A Report of the Safety Culture Task Force of the ACS Committee on Chemical Safety,” https://www.acs.org/content/dam/acsorg/about/governance/committees/chemicalsafety/academic-safety-culture-report.pdf (2012).

- Schröder, I., et al., “Laboratory Safety Attitudes and Practices: A Comparison of Academic, Government, and Industry Researchers,” Journal of Chemical Health & Safety, 23 (1), pp. 12–23 (2016).

- Zohar, D., and G. Luria, “The Use of Supervisory Practices as Leverage to Improve Safety Behavior: A Cross-Level Inter-vention Model,” Journal of Safety Research, 34 (5), pp. 567–577 (2003).

- Center for Chemical Process Safety, “Safety Culture: ‘What is at Stake’” in “Building Process Safety Culture ToolKit,” AIChE, https://www.aiche.org/ccps/safety-culture-what-stake (2020).

- Crowl, D., and J. Louvar, “Chemical Process Safety: Fundamentals with Applications,” 4th ed., Pearson Publishing, London, U.K. (2019).

- Hudson, P., “Implementing a Safety Culture in a Major Multi-National,” Safety Science, 45 (6), pp. 697–722 (2007).

- Ting, J. M., “Safety Moments in Chemical Safety Education,” Journal of Chemical Education, 98 (1), pp. 9–14 (2020).

- Conklin, T., “Pre-Accident Investigations: An Introduction to Organizational Safety,” CRC Press, Boca Raton, FL (2019).

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.