The devastating water crisis in Flint, MI, brought into focus the widespread issues plaguing U.S. water supply systems. As the water infrastructure continues to age, distribution pipes are deteriorating, potentially leaching toxic heavy metals and other contaminants into drinking water. Upgrading U.S. water systems will take years and trillions of dollars. In the meantime, to safeguard public health, it is crucial to monitor heavy metals and other contaminants throughout the water supply — particularly at the point of use.

Existing in situ water testing technologies are inadequate. Laboratory-based technologies can quantitatively measure aqueous heavy metal ion content down to parts per billion levels. However, these methods are costly (about $25–$50 per test) and require days for sample analysis to be completed, making them unsuitable for regular onsite detection. Qualitative detection methods are suitable for the field, relatively inexpensive (e.g., colorimetric test kits cost about $10/kit) and quick, but they are unreliable and provide inadequate sensitivity.

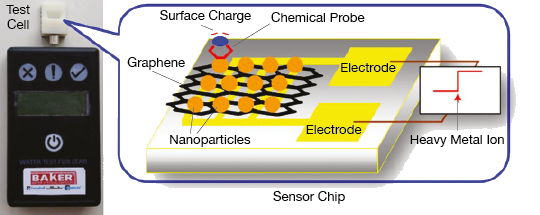

▲ A handheld device that includes a sensor enclosed in a test cell and attached to a digital meter can measure lead well below 15 ppb. The sensing chip is a field-effect transistor, with reduced graphene oxide (rGO) as the sensing channel and specific molecules attached to gold nanoparticles as probes. When heavy metals contact the probes, they react and change the conductivity of the rGO, which can be converted into the concentration of the heavy metal of interest.

With funding from the National Science Foundation (NSF), researchers at the Univ. of Wisconsin-Milwaukee (UWM) and NanoAffix Science, LLC, are developing a sensitive, selective, and cost-effective micro-sized sensor for the quantitative, real-time, in situ detection of heavy metal ions in water. The sensor is a field-effect transistor with reduced graphene oxide (rGO) as the sensing channel and specific molecules attached to gold nanoparticles as probes. The sensor shows promise for detecting a wide range of analytes, including heavy metal ions, bacteria, and nutrients in water.

Here’s how the sensor works. The conductivity of the rGO channel changes when chemicals/analytes bind to the probes anchored on the gold nanoparticles, e.g., through chelation reactions with heavy metals. The change in conductivity (measured in resistance) is proportional to the quantity of metal ion the sensor is measuring. The probe is designed to target a specific analyte.

The new technology allows real-time detection (no sample preparation is required) of contaminants with unprecedented sensitivity and selectivity in field settings. A handheld device is suitable for single-point testing, or the technology can be integrated into existing water equipment to provide continuous monitoring.

The researchers are collaborating with A.O. Smith, Badger Meter, and Baker Manufacturing to commercialize the sensing technology. For instance, A.O. Smith, a manufacturer of water heaters and water-treatment products, is interested in integrating the sensor into its water purifiers.

“This sensing technology gives us the ability to make sure contaminants are removed by our filtration products,” says Robert Heideman, senior vice president and CTO at A.O. Smith.

A prototype of the handheld device, consisting of the sensor housed in a test cell and attached to a digital meter, showed promise for rapid and selective detection of lead ions in drinking water. In the lab and in point-of-use field tests, it was able to measure lead well below the 15-ppb level required by the U.S. Environmental Protection Agency (EPA). In addition, the sensor detected Pb2+ within seconds — a feature promising for real-time monitoring.

The developers say that the availability of the handheld device, with an estimated retail cost of $60/unit (approximately $20 for the one-time sensor chip and $40 for the reusable meter), will contribute to improving the safety of drinking water and thus enhance public health.

The UMW and NanoAffix team is now testing the device in practical environments for real-time, in situ operation. Future work will focus on improving the performance of the device for continuous water monitoring and the detection of bacteria and nutrient contaminants, as well as on scaling up the process to manufacture these devices to reduce their cost.

This technology was funded through the NSF Partnerships for Innovation Program.

This article was prepared by the National Science Founda tion in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.