Become a seer of process safety incidents with carefully chosen process safety performance indicators (PSPIs). A PSPI program developed using the barrier-based or tier-based approach will serve as your crystal ball.

Process safety performance indicators (PSPIs) are key performance metrics that indicate when a process safety accident is most likely to occur. PSPIs can be categorized as either leading or lagging indicators. A leading PSPI is an active indicator of process safety performance; a lagging PSPI is a reactive indicator of process safety performance.

An effective PSPI program provides predictive signals that warn of deterioration in critical systems, which enables organizations to implement preemptive corrective actions. PSPIs can be used to benchmark process safety performance across an organization’s production facilities or to compare facilities owned by different companies.

The key to an effective PSPI program is selecting the right PSPIs. Various organizations have developed practices or standards that give guidance on PSPI programs (1–5). This article explains the barrier-based and tier-based approaches for selecting PSPIs and illustrates how they are used with two examples.

Barrier-based vs. tier-based approach

The barrier-based approach is defined by the U.K. Health and Safety Executive (HSE) in Health and Safety Guidance 254 (HSG254), and the tier-based approach is defined by the Center for Chemical Process Safety (CCPS) and the American Petroleum Institute (API). The tier-based approach has also been adopted by the International Association of Oil and Gas Producers (OGP) and the European Chemical Industry Council (CEFIC).

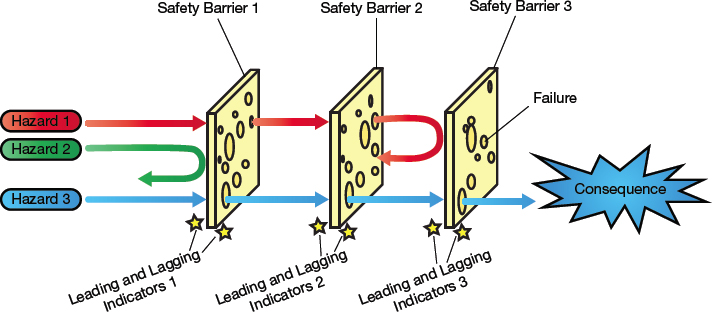

The barrier-based approach is based on the widely used Swiss cheese model (Figure 1), which shows how a series of safety barriers (i.e., risk control systems [RCSs]) can break down and allow hazards to propagate to loss events. Barriers are represented by slices of Swiss cheese, with the holes representing failures in the barrier. If an initiating event occurs and the holes in the barriers align, a loss event will occur.

▲ Figure 1. The barrier-based approach is based on the Swiss cheese model. Multiple safety barriers prevent hazards, but failures in the barriers may allow a hazard to occur. Leading and lagging PSPIs are defined around each safety barrier.

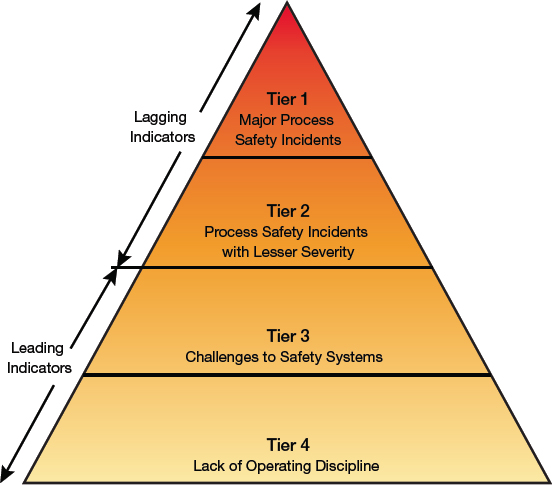

The tier-based approach is based on the safety pyramid (Figure 2). Safety accidents are placed on the pyramid according to their severity — high-consequence incidents are placed at the top of the pyramid, low-consequence incidents at the bottom. Tier-based PSPI programs recognize that lower-consequence incidents occur before incidents with higher consequences. If, for example, low-consequence events begin to occur more frequently, that might be an indicator that a higher-consequence event is imminent.

▲ Figure 2. The tier-based approach is based on the safety pyramid, where consequences increase in severity from the bottom to the top of the pyramid. Tier 3 and Tier 4 events are considered leading PSPIs, and Tier 1 and Tier 2 events are considered lagging PSPIs.

The pyramid is divided into four tiers of severity:

- Tier 1: major process safety incidents

- Tier 2: less-severe process safety incidents

- Tier 3: challenges to safety systems

- Tier 4: lack of operating discipline (e.g., unsafe behaviors).

Leading and lagging indicators

Each approach defines leading and lagging indicators differently. The barrier-based approach defines leading and lagging indicators around each of the safety barriers. Lagging indicators provide reactive monitoring of the barriers through incident investigation, near-misses, and weaknesses discovered in the system. Leading indicators provide active monitoring of the barriers, and help to ensure the barrier’s continued effectiveness at reducing process safety risks.

For example, a generic leading indicator of staff competence is the percent of employees involved in hazardous operations who have received training and have proven their competency. A lagging indicator of staff competence is the number of process safety incidents, including near-misses, caused by a lack of staff competence.

The tier-based approach uses the safety pyramid to define leading and lagging indicators. Tier 1 and Tier 2 events are deemed lagging indicators, while Tier 3 and Tier 4 events are deemed leading indicators. The following examples illustrate this concept.

Example 1: Manual powder transfer

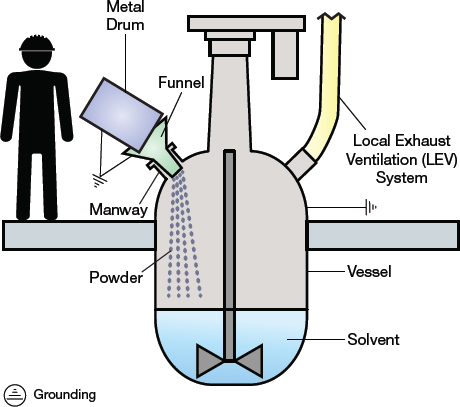

In Figure 3, an operator manually transfers a flammable powder from a metal drum to an inerted reactor containing a flammable liquid. The solvent already present in the reactor has a low flashpoint and a flammable atmosphere is present in the headspace. The manway is equipped with a local exhaust ventilation (LEV) interlock such that when the manway is opened, the LEV turns on automatically.

▲ Figure 3. A flammable powder is manually transferred into a reactor that contains a low flash point solvent.

This operation presents several hazards:

- An explosion or flash fire could occur at the manway or inside the reactor. Electrostatic discharge (i.e., a spark) from the metal funnel or the metal drum could ignite the powder, solvent vapors, or both.

- The operator could be exposed (via inhalation) to high concentrations of vapors and dust particles above the safe exposure limit.

- Liquid could be released if there is a mechanical failure (possibly caused by corrosion) of the vessel.

Several safety barriers can help to prevent these incidents:

- grounded metal funnel and metal drum

- effective operation of the LEV

- a mechanically sound reactor vessel.

Leading and lagging PSPIs can be developed by either the barrier-based or tier-based approach.

Barrier-based PSPIs. For the first hazard — an explosion or fire — the desired safety outcome is the absence of a fire or explosion caused by ungrounded conductive plant equipment. This hazard is prevented by the site grounding system.

A lagging indicator for the grounding system safety barrier is the number of manual transfer operations that have led to a fire or explosion because of ungrounded plant equipment. This lagging indicator provides information on the historic effectiveness of the site grounding system. As part of a PSPI program, this indicator helps characterize the effectiveness of this safety barrier. By providing a running count of such incidents, the PSPI program should drive the plant to address any issues related to this safety barrier.

Effective implementation of the grounding system safety barrier requires employee competency — the drum and funnel must be grounded correctly — and equipment integrity — the grounding wires must not be broken. Leading indicators include the percentage of employees involved in manual transfer operations who are sufficiently competent in grounding, and the percentage of grounding wires that failed an inspection.

Tier-based PSPIs. The standards that define the tier-based approach provide a list of leading and lagging indicators.

Lagging indicators are the Tier 1 and Tier 2 events. A Tier 1 lagging indicator could be a fire or explosion that results in $25,000 or more of direct costs to the company, or an employee, contractor, or subcontractor fatality. Tier 2 lagging indicators are similar, but have lower thresholds: a fire or explosion that results in $2,500 or more of direct costs to the company, or an employee, contractor, or subcontractor recordable injury.

Although leading indicators can also be selected from the predefined lists of Tier 3 and Tier 4 events, practitioners are encouraged to look at hazards specific to the site or historic incidents related to relevant leading indicators. For illustration purposes, this example uses indicators from the standards. Leading indicators could be the percentage of safety-critical tasks observed for which all steps of the relevant safe working procedure were not followed, and the percentage of inspections of safety-critical equipment completed on time.

Example 2: Automatic liquid transfer

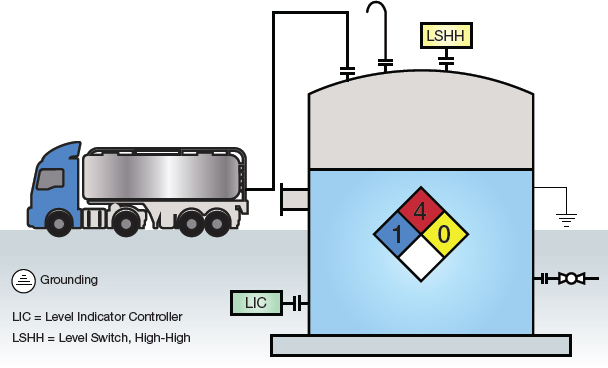

A standard atmospheric storage tank containing a flammable liquid (Figure 4) is filled from a tanker; after the inventory has been transferred, the liquid is pumped to the process as needed. With the exception of the tanker, the system is automatic.

▲ Figure 4. A storage tank that contains a flammable liquid is filled by a tanker. The contents of the storage tank are pumped to the process as needed.

The potential hazards of this process include:

- an explosion inside the storage tank

- overfilling of the storage tank and release of liquid into the surrounding dike

- a fire in the dike

- overpressure of the tank due to inflow of liquid.

Safety barriers that address these hazards include:

- measures to eliminate or prevent ignition sources inside the storage tank, such as explosionproof instruments and proper grounding of the storage tank

- a level indicator controller (LIC) on the tank that serves as a basic process control system, and a level switch, high-high (LSHH) that cuts off the inflow of liquid if the liquid level becomes dangerously high

- measures to eliminate or prevent ignition sources in the dike, such as explosionproof pumps and motors and proper grounding of plant equipment

- a breathing vent that protects the storage tank from being pressurized during filling.

Barrier-based PSPIs. Consider the second hazard — overfilling of the storage tank and release of liquid into the surrounding dike. The desired safety outcome is to not overfill the storage tank and not experience a loss of containment.

The safety barriers are the LIC and LSHH. Therefore, lagging indicators are the number of overfilling incidents caused by failure of the LIC and/or LSHH and the number of overfilling near-misses due to failure of the LIC and/or LSHH.

A leading indicator for this safety barrier is the percentage of overfilling protection device(s) (e.g., LSHH) that pass inspection and testing.

Tier-based PSPIs. The lagging indicators could be the same Tier 1 and Tier 2 events as in Example 1. Leading indicators could be the activation of the safety-critical systems (e.g., LSHH) and the percentage of inspections of safety-critical equipment completed on time.

Concluding thoughts

The two methods for selecting PSPIs offer different advantages (Table 1). The barrier-based approach is flexible and creates a customized, site-specific set of indicators. The tier-based approach is generic, but produces a set of indicators that can be used for benchmarking.

| Table 1. The barrier-based and tier-based approaches to developing PSPIs have different pros and cons. | ||

| Barrier-Based Approach | Tier-Based Approach | |

| Summary |

|

|

| Pros |

|

|

| Cons |

|

|

Although custom indicators are useful at the facility or site level, they can be difficult to use for benchmarking at the corporate level. Conversely, generic indicators that can be used for benchmarking are useful at a corporate level, but less useful to individual facilities.

Selecting the right PSPIs is only one step in implementing an effective PSPI program. A successful program also includes:

- a champion to shepherd the initiative forward

- an implementation team that utilizes a data collection and analysis system

- active involvement of senior management in the development of indicators, as well as during corrective action.

Process safety performance indicators are only useful and effective if they are maintained by employees who are aware of the hazards associated with the process and have access to good data.

Literature Cited

- Health and Safety Executive, “Developing Process Safety Indicators: A Step-by-Step Guide for Chemical and Major Hazard Industries,” HSG254, HSE, London, U.K. (2006).

- American Petroleum Institute, “Process Safety Performance Indicators for the Refining and Petrochemical Industries,” API RP 754, API, Washington, DC (2010).

- Center for Chemical Process Safety, “Process Safety Leading and Lagging Metrics,” CCPS, New York, NY (Jan. 2011).

- International Association of Oil and Gas Producers, “Process Safety: Recommended Practice on Key Performance Indicators,” OGP, London, U.K. (Nov. 2011).

- European Chemical Industry Council, “Guidance on Process Safety Performance Indicators,” CEFIC, Brussels, Belgium (May 2011).

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.