Reproducing the fats found in foods like chocolate in a way that convincingly recreates the original food’s taste and texture has long been a challenge for food scientists. Now, precision fermentation has allowed researchers to optimize lipid production to meet functional and nutritional targets.

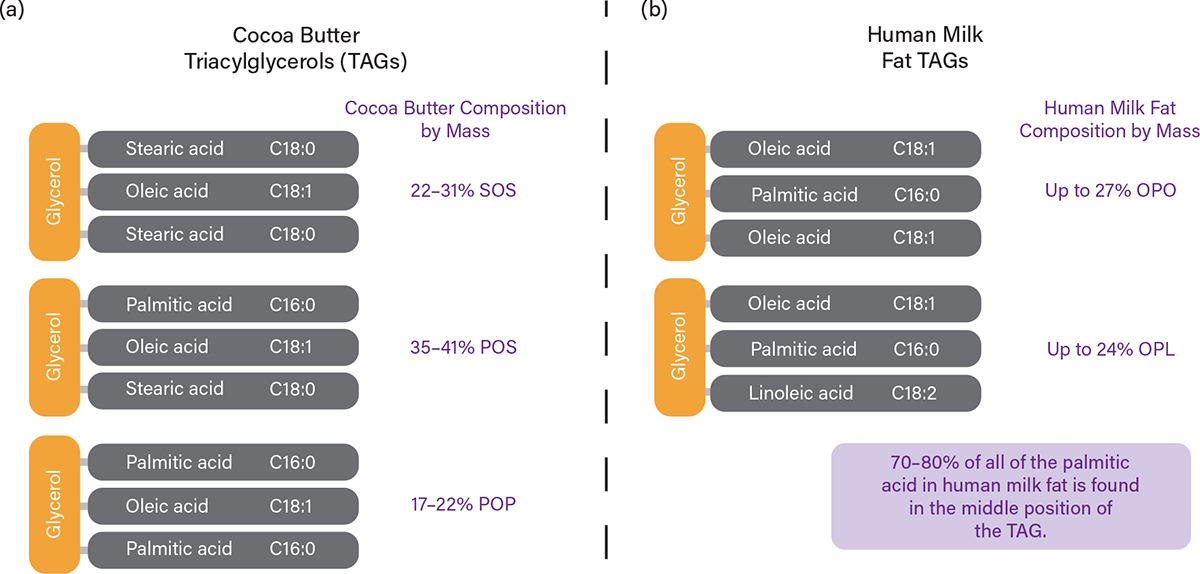

Dietary fats, primarily triacylglycerols (TAGs), are essential nutrients that give the body energy and enable cell functions. Some TAG-rich oils and foods, like canola oil, olive oil, palm oil, and peanut butter, are derived from plants, while animal fats, like lard and dairy butterfat, are also common TAG sources. The molecular and structural diversity of TAGs comes from the type and position of the fatty acids, as well as their length and saturation. These fatty acids are bonded to a glycerol backbone (Figure 1). This molecular structure dictates a fat’s physical properties and nutritional values, and it is crucial in determining its texture, taste, and shelf-stability (1). Furthermore, the specific arrangement of fatty acids in TAGs affects their digestibility and metabolism in the body, influencing nutrient absorption and overall health benefits (2). This structural variability creates numerous distinct fat molecules with unique properties and biological implications.

▲Figure 1. Triacylglycerols (TAGs) include a glycerol backbone connecting three variable fatty acid chains, and the composition of these fatty acids contributes to a food’s specific taste, nutritional value, and texture. (a) Cocoa butter and (b) human milk fat are both rich in TAGs. Discovering a method for manufacturing a cocoa butter substitute would help alleviate supply chain strain and environmental impact, while producing an adequate human milk fat substitute could improve the nutritional value of conventional infant formula.

The unique molecular structure of TAGs plays a particularly important role in two major food categories: confectionery products and infant nutrition. In chocolate, the functional properties such as snap, melt profile, and smooth mouthfeel are dictated by the unique TAG composition of cocoa butter. The three dominant TAGs in cocoa butter are stearic-oleic-stearic (SOS), palmitic-oleic-stearic (POS), and palmitic-oleic-palmitic (POP) (Figure 1a). The specific blend of these TAGs allows effective control over the cocoa butter’s crystallization — a process called tempering — which gives chocolate its characteristic gloss and firm texture.

Cocoa butter production, however, is susceptible to supply chain shocks due to climate change because of cocoa plantation geography. Cocoa trees only grow within a narrow equatorial band, primarily in West Africa, and are highly susceptible to weather variability, disease, and geopolitical disruption. Since 2024, cocoa prices have surged 300% and reached a historic high of $12,000 per ton (3), intensifying concerns about supply chain resilience. To mitigate these issues, the food industry has turned to cocoa butter equivalents (CBEs), which are typically made by fractionating and blending tropical fats such as palm oil or shea butter. These fats can be tailored to approximate the TAG profile of cocoa butter. However, they often fall short of replicating its precise composition (4). Moreover, the tropical fats used to produce CBEs face similar environmental and economic vulnerabilities as cocoa (5).

TAG structure is also critical in the context of human milk fat, which serves as the nutritional gold standard for infant formula. Human milk fat is characterized by a high proportion of its palmitic acid located at the sn-2 position, with approximately 70% to 88% of the total palmitic content esterified at this central position (Figure 1b) (6). This structural feature promotes better absorption of fat and calcium, reduces the formation of insoluble fatty acid soaps in the gut, and supports gastrointestinal comfort (7). Among the most abundant TAGs in human milk are oleic-palmitic-oleic (OPO) and oleic-palmitic-linoleic (OPL), though the overall TAG composition varies significantly depending on maternal diet, geography, and other factors. This sn-2 enrichment has been linked to improved digestive efficiency and overall infant health outcomes.

However, most commercial infant formulas consist of vegetable oils, in which almost none of the palmitic acid is found in the sn-2 position (6). Some formulas include bovine milk fat, which contains a higher proportion of sn-2 palmitic acid than vegetable oils but still falls short of the levels found in human milk. To more closely mimic human milk fat, specialty fats manufacturers like Bunge, AAK, and Wilmar have developed structured lipids such as OPO using enzymatic interesterification. This process typically starts with palm-derived tripalmitin and oleic-rich oils and uses lipase enzymes to rearrange the fatty acids. While effective, this method requires high-purity inputs and multiple processing steps, driving up cost and limiting widespread adoption. Currently, OPO is primarily used in premium infant formulas in China, while most U.S. and European formulations continue to be primarily vegetable oils.

These examples illustrate a common limitation in the current supply of structured fats. Agricultural sources provide essential feedstocks with defined and primarily consistent fatty acid and TAG profiles, but they offer limited flexibility when tailoring lipid structures for specific functional or nutritional outcomes. Existing methods, such as enzymatic interesterification, fractionation, and blending, can modify or combine natural fats to approximate desired profiles (8). However, these approaches are constrained by the composition of the starting materials, require extensive processing, and may still fall short of replicating specific TAG structures.

At Yali Bio, we are developing a precision fermentation platform to rapidly and precisely design structured lipids, without the long development cycles associated with plant genetics or agricultural production. Rather than waiting months for a crop to grow and be harvested, targeted fats can be produced in a fermenter within days. The Yali OS precision fermentation platform enables the optimization of lipid structures that meet specific functional and nutritional targets. This article highlights key challenges in this emerging field, including the complexity of lipid structural analysis, the difficulty of design-build-test-learn cycles, and the scalability of precision fermentation-based technology. Addressing these challenges will be critical to realizing the full potential of precision fermentation for structured lipid production...

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.