Nearly 1.3 billion tons of food — almost one-third of the world’s food supply — goes to waste each year. Producing and disposing of this much wasted food consumes 17.6 billion m3 of water and generates 193 million m.t. of greenhouse gases, according to the United Nations (UN) Food and Agriculture Organization (FAO) and the UN Environment Program. Novel food preservation technology could help feed every undernourished person on the planet and reduce the environmental impact of such waste.

Food waste is a particularly challenging problem for highly perishable items such as fruits and vegetables, of which the FAO estimates half are wasted. Studies show that about 50% of this food waste can be prevented by extending the shelf life. Shelf life is reduced by several factors including moisture loss, which leads to changes in texture, flavor, and appearance, and gas exchange, which results in enzymatic oxidation and decay.

Refrigeration and plastic packaging materials are effective ways of controlling gas exchange and moisture loss, but refrigeration is not always available and plastic packaging is generally frowned upon by consumers or banned by some governments.

Another industry standard is the application of edible coatings. These coatings are expected to provide a moisture barrier on the surface of produce and help alleviate the problem of moisture loss.

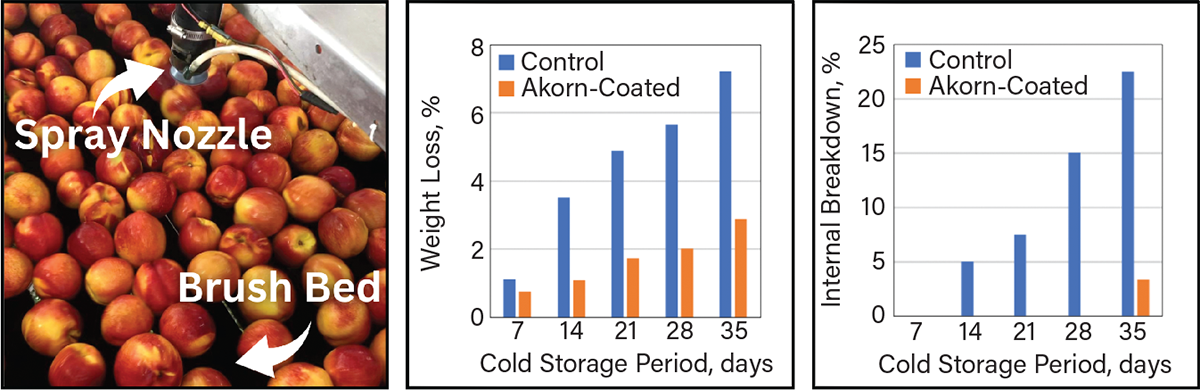

▲ Application of the Akorn coating on nectarines reduces moisture loss by 60% and incidence of internal breakdown by 80%, resulting in improved delivered quality and reduced rejection rates compared to control. The control group of nectarines were uncoated because the vast majority of global stone fruit production is not coated.

Since the 1930s, plant or petroleum-derived waxes have been commercially applied as protective coatings mainly for apples and citrus to reduce moisture loss and impart a glossy finish. However, waxes are poor gas barriers, which makes them generally unsuitable for those fruits that continue ripening post-harvest. These fruits require coatings that reduce gas exchange and respiration rate, which by extension reduce ripening speed.

With funding from the U.S. National Science Foundation (NSF), Akorn Technology (www.akorn.tech) has developed a composite coating that integrates a protein and lipid together to improve functionality. The protein — corn zein — is generally soluble in aqueous ethanol and a few other solvents, but not in water. Akorn’s patent-pending process makes zein dispersible in water at concentrations between 5% and 10%, an order of magnitude higher than previously achieved. This allows the creation of a zein colloid that forms an invisible edible film when applied to the surface of fresh produce. The protein provides the film integrity, entrapping the lipid component. The protein acts primarily as a gas barrier while the lipid component acts primarily as a moisture barrier.

This enhanced functionality is ideal for highly perishable, globally produced crops — like apples, mangos, avocados, and tropical and stone fruits — nearly doubling their shelf life. The coating also reduces internal breakdown (flesh browning) that occurs when some fruits such as mango and stone fruit are brought to room temperature after extended cold storage.

Akorn has developed several formulations of the coating that are suitable for different crops, employ only naturally sourced materials, and are approved by regulatory authorities for use worldwide. All ingredients are readily and abundantly available, which minimizes production costs. They are completely free of corrosive, flammable, or hazardous materials. In modern processing facilities, they may directly replace wax in existing waxing systems. Most importantly, the Akorn coatings can be applied with simple methods and under ambient conditions at the farm or plantation, extending shelf life of produce and improving market access for small holders.

The benefits stemming from the Akorn coatings are well illustrated by the case of Blue Skies, a supplier of premium fresh cut fruit to the U.K. market. Blue Skies sources its mango from Africa, where the fruit is harvested at optimal maturity to ensure the best taste. “Our studies have shown that by applying the Akorn coating, we can reduce waste by 30%, return more value to the African communities that produce the fruit, and still deliver cut mango products with our signature ‘Fresh from Harvest’ taste,” says Hugh Pile, CEO of Blue Skies.

This technology was funded through the NSF Small Business Innovation Research Program.

This article was prepared by the National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.