Processed foods are a staple in the American diet, comprising more than half of adult energy intake. When eaten in excess, these shelf-stable, convenient, and tasty foods are known contributors to obesity, heart disease, cancer, Type 2 diabetes, and gastrointestinal disorders. However, changing habits and taste preferences to encourage healthier eating is a challenge. Processed foods are known for their excellent sensory properties and high palatability but are often calorically dense and contain elevated levels of starches, sugars, saturated fat, and salt, and low amounts of beneficial macro and micronutrients. Food is a complex matrix of fats, fibers, starches, sugars, proteins, vitamins, minerals, and water, all of which contribute to sensory qualities such as texture, mouthfeel, and flavor perception that are critical in the experience of food consumption.

In September 2022, the U.S. Food and Drug Administration (FDA) released a proposal to modernize the definition of “healthy” foods as part of a larger initiative to improve the American diet. This proposal could transform the food industry. Most seemingly healthy packaged foods would not meet the new FDA definition, creating a new technical challenge in the food industry to develop processed foods that meet the new requirements. Often times, healthier snack foods that contain higher amounts of beneficial macronutrients, such as protein and fiber, struggle with dense textures due to reduced levels of starch, higher water absorption capacity, and disruption of expansion networks. Developing healthier options that maintain fidelity to traditional processed foods while meeting consumer expectations is a technical challenge.

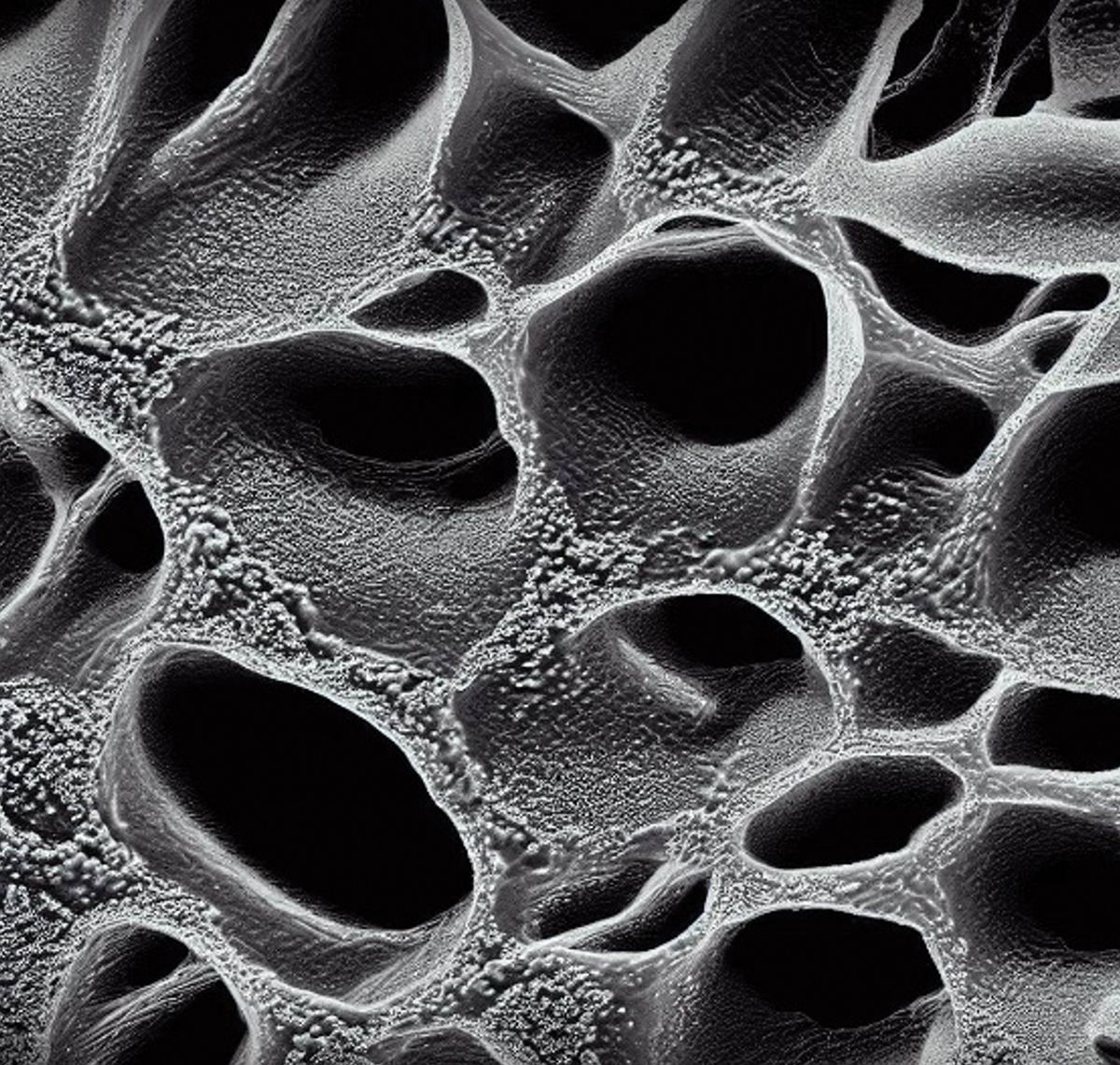

▲ Antithesis’ key innovation involves creating viscoelastic doughs based on legume proteins and fibers. These hold the structure together during cooking and form air pockets, allowing for the development of an interior porosity that mimics the textural complexity of foods such as crackers, cereals, breads, muffins, and pizza crusts. In this 3D rendering depicting the interior of a cracker, the average pore size is around 194 µm.

Enter Antithesis Foods, an Ithaca, NY-based start-up founded by food scientists during their graduate studies at Cornell Univ. and funded by the U.S. National Science Foundation (NSF). Recognizing the gap in the market between the affordability and palatability of conventional processed foods, and the cost and inferior taste of healthier alternatives, the company decided to make healthy snack foods that mimic the structure and taste of mass market foods, while also providing “stealth health” through nutritionally dense ingredients.

Antithesis’ patent-pending invention creates snack foods with aerated structures that mimic gluten, but their viscoelastic doughs are based on legumes. Legume proteins and fibers hold the structure together during the cooking step, forming air pockets and allowing for the development of an interior porosity similar to bread and other wheat-based products. The start-up’s snack foods have palatable and craveable flavors and a textural complexity that mimics foods like chips, cookies, and cereals — but with more protein and fiber and less carbohydrates, saturated fat, and added sugar.

The dough on which these snack foods are based differs highly in its rheological properties in comparison to the gluten-based doughs for which most manufacturing lines are configured. The primary innovation lies both in formulation and downstream processing, overcoming the challenges of variation in product behavior, quality, and manufacturability caused by nutritionally dense food matrices. A variety of manufacturing lines with different drying technologies have been evaluated for their ability to maximize throughput and minimize input costs while simultaneously preserving fundamental pleasurable textural properties.

Antithesis partners with retailers, brands, and manufacturers to launch customized food products: “As a fellow food industry innovator, I have great respect for Antithesis Foods and our collaboration to incorporate ReGrained SuperGrain+ materials into their technology,” says Dan Kurzrock, CEO and Co-Founder at Upcycled Foods, Inc. “Antithesis’ products are exceptionally well-differentiated in the better-for-you and functional food space and the resulting food products are delicious and nutritious food products ready for commercial scale. We look forward to continuing to innovate together to unlock more nutritious and sustainable supply chains in the food system.”

Today, Antithesis is scaling its production capacity with the goal of manufacturing multimillions of servings annually and supporting customers nationwide.

This technology was funded through the NSF Small Business Innovation Research Program.

This article was prepared by the National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.