Formulators use four main tools to tune the physical properties of a product and create the qualities and functionality that consumers expect.

To be competitive in the multibillion-dollar consumer products industry, formulators must consider not only product functionality, but also marketability. An attractive product is one that is visually pleasing, pleasant feeling, and has overall perceived functionality. A quick walk through the skincare aisle of a drugstore will reveal products touted as “ultralight,” “weightless,” and “touchable.” Sticky, oily, and phase separated products are unacceptable.

Desirable perception parameters can be achieved by modifying the physical properties of the product rather than changing its chemical composition. One technique is to adjust the material’s surface tension and viscosity by incorporating one or more of the myriad available surfactants, polymers, and colloids approved for consumer products. The physical structure of each of these additives can be further considered to achieve target product quality. For example, adding surfactants of different chain lengths and at different concentrations creates different micellar structures. Polymers can have the same chemical makeup but vary in length or degree of branching. Finally, colloid size and surface roughness can alter the way a product flows and interacts with skin.

Although surfactants, polymers, and colloids can be used to fine-tune the product, they can also create processing roadblocks. The unique viscoelastic properties that improve marketability and delay phase separation can also cause process lines to plug and mixer impellers to seize. Understanding how a material behaves under shear is therefore critical to process development. In academia today, we study how complex fluids can address unique challenges to enable the creation of new products, while remaining grounded in the ever-present context of manufacturability and scaleup.

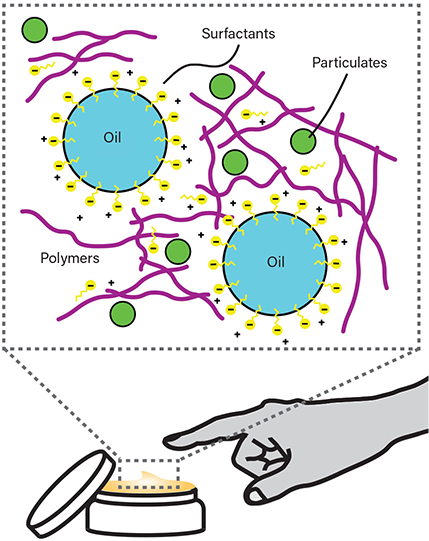

Formulators have a toolbox of four main components at their disposal to tune the physical properties of a product (Figure 1):

- the dispersed phase, e.g., oil/water emulsions or solid particulates

- the continuous phase, i.e., bulk oil or water as the fluid phase

- surfactants, which stabilize the otherwise immiscible phases

- rheology modifiers, i.e., polymers or particulates that change product consistency.

▲Figure 1. The main components used to formulate a broad class of consumer products include the dispersed phase (e.g., oil droplets or particles), the continuous phase, surfactants, and rheology modifiers (e.g., polymers). When a person interacts with a consumer product, the solid- and liquid-like properties of the components dictate the consumer’s perception.

This article provides an overview of the formulation components, how they contribute to improving skin-feel (e.g., lubrication and friction), and how their rheological properties influence product microstructure and processing conditions.

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.