Use molecular analysis to reveal hidden value during process development.

The goal of process synthesis is to determine the most appropriate processing routes, as well as the optimal catalyst, reaction and separation technologies, and system design — all while minimizing capital and operating costs.

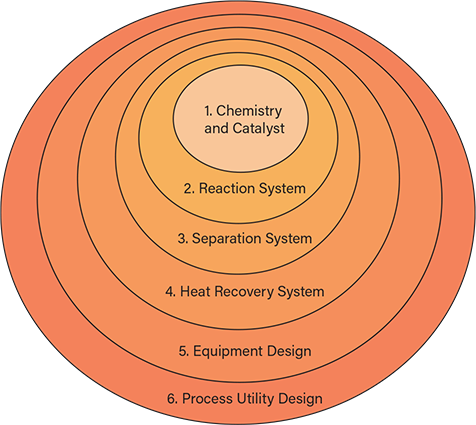

In general, process synthesis follows a complex series of steps (Figure 1). First, the chemistry and catalyst are developed. Next, the reaction system and product separation system are selected. The system of heat recovery is then designed, as well as the equipment and utility systems (1, 2). Complexity in design grows exponentially if interactions among catalyst, reaction system, and separation system designs are included.

▲Figure 1. Process synthesis follows this sequence of steps from the inner circle outward.

Industrial practice relies heavily on practical experience and judgment. Due to its trial-and-error nature, process synthesis is regarded as more art than science, which does not guarantee the best design for the overall system.

Current methods of process synthesis are mainly based on macroscopic analysis and do not exploit microscopic effects at the molecular level. These methods are largely incapable of leading to breakthroughs in process development.

This article describes a new method of process synthesis based on novel molecular analysis. This method identifies the best molecular transformation routes by optimizing reaction pathways (chemistry), catalyst (material), and process design (engineering) (3). The article also discusses three examples that demonstrate the value of applying this approach to catalyst development and process synthesis.

In the case of catalyst development, molecular analysis can reveal new directions to improve catalyst selectivity and activity. For process synthesis, molecular information can generate reaction and separation designs (including hybrid systems) and new process concepts.

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.