Plastics can be made more sustainable by using abundant, low-cost agricultural feedstocks. To that end, researchers in the Industry-University Cooperative Research Center (IUCRC) for Bioplastics and Biocomposites (CB2), with support from the U.S. National Science Foundation (NSF), are developing polymers made from commodity fats and sugars whose global production far exceeds dietary demand, such as soybean oil, glycerol, starches, and fruit-derived acids. By valorizing these inexpensive, renewable materials, CB2 aims to create drop-in materials and processes that support U.S. agriculture and industry while enabling plastic recycling.

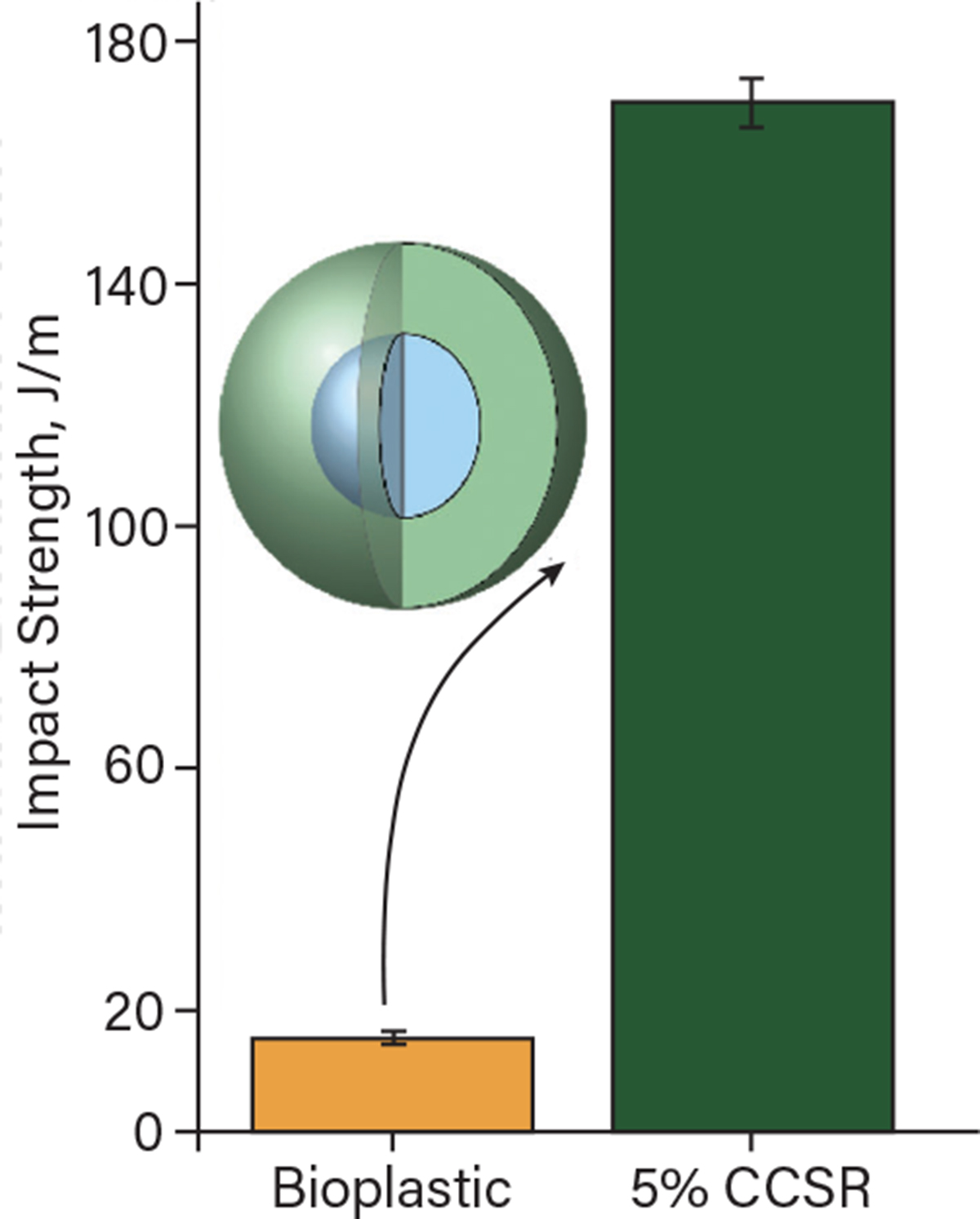

To improve the performance of biodegradable bioplastics such as polylactic acid (PLA), CB2 has tackled the longstanding challenge of brittleness. Using glycerol-based monomers derived from biodiesel coproducts, researchers synthesized waterborne core-shell particles featuring a soft, rubbery solketal-acrylate core and a rigid, compostable acrylic shell. When blended into PLA at 5–20 wt%, these particles boosted impact resistance by nearly an order of magnitude while preserving tensile strength and compostability. Because the modifiers are bio-derived and biodegradable, they are more sustainable than traditional PLA tougheners.

▲ Blending newly developed glycerol-based compostable core-shell rubber (CCSR) into polylactic acid (PLA) at 5–20 wt% boosts the impact resistance of the final product by nearly an order of magnitude.

At the end of a plastic’s lifecycle, biodegradation is valuable for plastic items likely to escape into the environment. However, this represents a permanent loss of resources, considering the significant energy plastics manufacturing requires. Economical recycling strategies that enable repeated recovery and reuse would provide a bountiful supply of materials without waste accumulation or virgin resource extraction. However, state-of-the-art recycling practices struggle with issues like mixed-waste streams and deteriorated product quality.

CB2 uncovered a surprising breakthrough: a tandem caustic alcoholysis/hydrolysis recipe that depolymerizes any polyester, including bottles, textiles, and multilayer films. This process reaches >95% conversion in as little as 5 min for powders and 45 min for unprocessed bottles at 50–80°C and ambient pressure, yielding virgin-grade monomers. The patent-pending process is effective even with solid-state plastics due to phase transfer catalysts that shuttle hydrophobic nucleophiles to the hydrophobic plastic surface. Molecular fragments are sloughed off into solution, where they are hydrolyzed into monomers and precipitate for easy recovery. Because the reaction tolerates pigments, fillers, and cotton fibers, it transforms mixed waste into purified monomers suitable for re-polymerization, thus preserving material value without costly sorting.

“This establishes an unprecedented development in the field of polyester recycling, which currently suffers from unavoidable deterioration in quality and engineering performance during mechanical recycling,” said Richard Hoch, Senior Manager of Sustainability at Diageo.

Industry members of CB2 were central to both advances. EvolveGolf guided the Center toward high-performance injection-moldable biodegradable components, while 3M scaled pilot batches to convert novel polyesters into prototype films. ADM supplied non-food-based building blocks, and Diageo blow-molded demonstration bottles from the recyclable polyethylene terephthalate (PET) and benchmarked them against current recycling streams. Collaborations with CB2 members shortened the distance from lab bench to commercial validation and supplied guidance on performance and market needs.

The biodegradable-modifier program is now entering field trials in marine-compostable sporting goods and single-use food packaging where rapid disintegration is critical. Concurrently, the low-temperature depolymerization technology is being engineered into a continuous-flow reactor targeting waste textiles and bottles. Early technoeconomic models suggest that the cost of recycled PET may approach that of virgin PET as the process is scaled up and optimized.

By developing materials that degrade sustainably and processes that recapture value, CB2 attacks the plastics-waste challenge from both ends and exemplifies how polymer science fundamentals coupled with strong industry partnerships can deliver practical solutions to a persistent environmental problem.

This research was funded through the NSF Industry-University Cooperative Research Centers (IUCRC) program.

This article was prepared by the U.S. National Science Foundation in partnership with CEP.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.