Sections

Standard engineering pedagogy often fails to fully prepare students for the transition from school to the workplace. This article presents the many ways that students, professors, and employers can help bridge this gap.

Engineering faculty members are dedicated to student learning, and they measure achievement through different quantifiable metrics such as the fundamentals of engineering (FE) exam, student contests, accreditation, and employment statistics. However, a gap often exists between the way schools and industrial workplaces function, share critical information, and approach problems. This article explains the gap and how to best prepare students for fitness in this new culture.

The gap refers to the cultural divide that new graduates must cross when entering industrial practice. There are multiple aspects to the divide. School days are youth-dominated and center on personal independence and freedom. By contrast, the culture of employment is dominated by older generations, interdependence, and commitment to the enterprise’s aspirations. Additionally, to maximize learning and to legitimize the testing of fundamentals, the concepts taught in classrooms are usually idealized, isolated, and science- and math-oriented. In the workplace, problem-solving in engineering practice is characterized by complexity and non-ideal conditions. Engineering is open-ended, with many acceptable answers. In school, success is measured by demonstrating that students have learned topics and technical skills. In contrast, success in employment often requires convincing superiors and subordinates to respond appropriately to what the engineer’s analysis suggests. Finally, partial credit in school is widespread and expected by students. In the workplace, partially correct solutions are not accepted, and they require further attention.

Much has been written about the education-to-practice gap (1–7). It takes about two years after graduation for a new employee to cross it, and many programs are working to help young professionals bridge the gap (3). AIChE’s Institute for Learning and Innovation (ILI; www.aiche.org/ili) seeks to enhance the in-school experience and support continued education, improving the reach and scalability of educational content (8). Resourcium (www.resourcium.org) provides practice-relevant materials for classroom use. The Institute of Electrical and Electronics Engineers’ (IEEE) Control Systems Society (www.ieeecss.org) and the International Federation of Automatic Control (IFAC; www.ifac-control.org) have industry committees seeking to integrate academia and industry.

A 2015 study conducted by AIChE for the National Science Foundation (NSF) sought input from engineers and employers in industry on topics that they believed academia should renew its focus (9). Some of the primary takeaways were a widespread need for improved written and verbal communication skills, the ability to function in teams and in leadership positions, and further instruction on the application of process dynamics, controls, and safety. All of these real-world skills are the skills valuable to industry.

The gap represents a major cost to employers. Chemical engineering programs in the U.S. graduate about 10,000 students per year (10), and 85% of those students eventually enter engineering practice. The average full-time entry salary is about $75,000 per year (11), but the cost to a business nearly doubles that of the employee’s salary alone. If a new employee initially works at half of their potential productivity and requires two years to reach 100%, the cost of lost productivity to the U.S. chemical process industries is about $320 million per year.

The gap is not an issue of students graduating without the technical skills required for their jobs. Although new employees need to learn new processes and supporting technology, they have the skills to do so. Likewise, the gap is also not about a lack of willingness to work. New graduates are eager to use their abilities. The gap is a disconnect between acquired and necessary skills that arises from the disparity between the ways that students are taught and socialized and how they are required to function in industry. Before new employees can self-redirect their understanding and supervisors can better coach employees through the transition, all participants need to understand the gap to reach a successful collaboration between industry and education.

What is the gap?

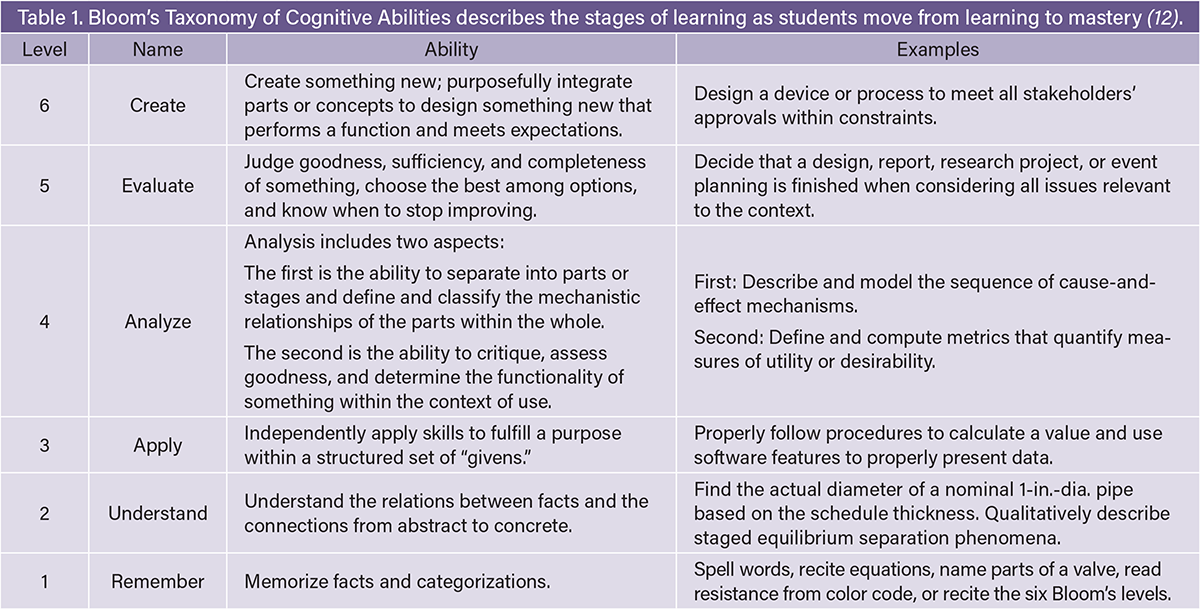

There are many ways to characterize the gap. Bloom’s Taxonomy of cognitive abilities, as described in Table 1, is one useful approach (12). In this general categorization of abilities, skill is broken up into six levels that range from basic recollection to the ability to create something new based on mastered skill. These six levels are the ability to remember, understand, apply, analyze, evaluate, and create. The first three skills describe one’s ability to learn, understand, and apply information within a certain structured set of “givens.” Analysis requires the ability to separate a subject into parts or stages and define and classify the mechanistic relationships of the part within the whole, as well as the ability to critique and assess quality within the context of some use. Evaluation requires a student to judge the goodness, sufficiency, and completeness of something, choose the best among options, and know when to stop improving. Finally, creation occurs when one can combine complex concepts to create something entirely new.

Unfortunately, classroom education tends to keep students operating in the three lower cognitive levels: follow the instructor, memorize and understand, then demonstrate by application on simplistic problems or lab exercises. While it is true that the capstone college courses seek to move students into the upper three levels, those are a small portion of the student’s total educational experience. Even in the capstone courses, the instructor prescribes the topics and method of learning, and the instructor evaluates student proficiency.

When students perceive that operating in the first three levels is professional preparation, this misdirects students’ understanding of being a professional partner in the enterprise. The job of a practitioner is to bring projects and ideas to fruition. In this role, learning and instruction are valued when necessary to support an employment function. Generic learning can be both personally and professionally rewarding, but “learning for learning’s sake” is no longer the employee’s job.

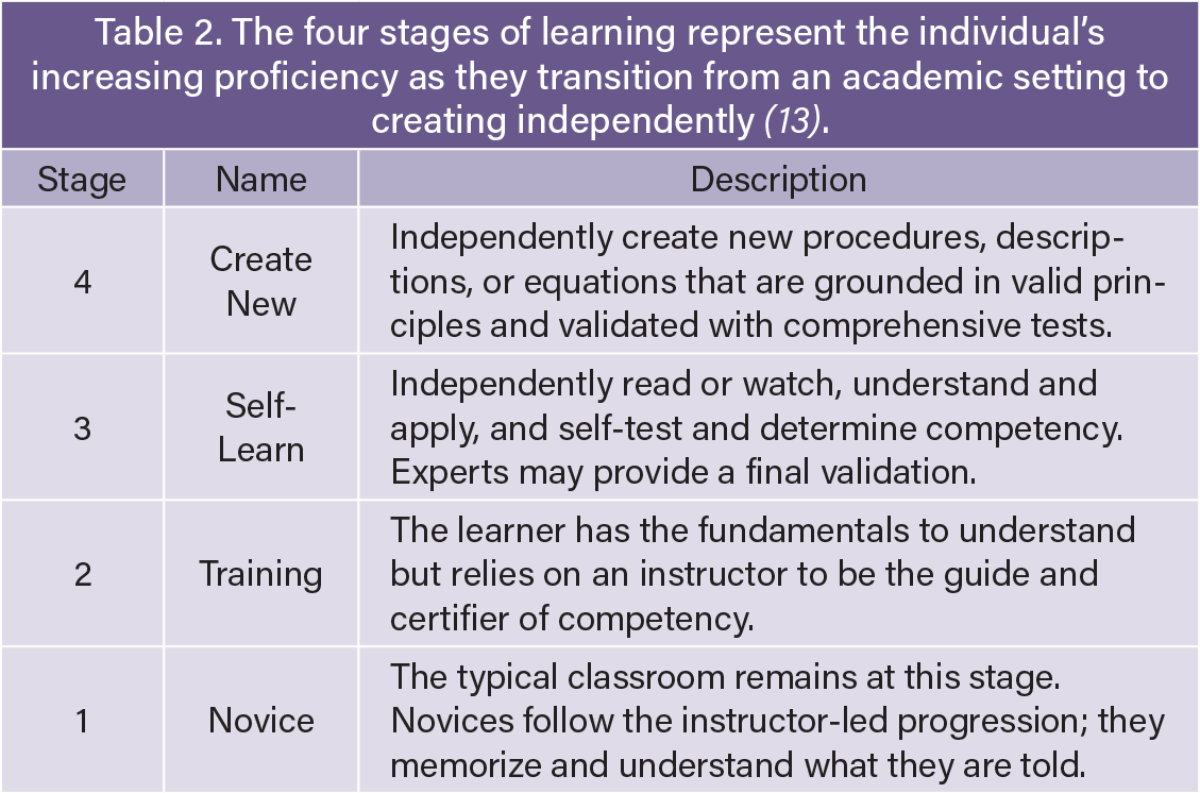

Reviewing the stages of learning presented in Table 2 can also be helpful in understanding the gap (13).

The first stage, novice, represents instructor-led learning, with generic testing on relatively simple questions. Novices benefit from direction, close learning supervision, and detailed guidance about every step and concept. Idealization and isolation of concepts are needed. However, idealization in the first stage misrepresents the complexity and context of application. Furthermore, school systems often encourage students to follow instructors instead of promoting mastery and learning progression. There is too little time to cover all essential topics in the span of an undergraduate education. It is expedient for education to keep students at the novice stage in each subject.

The second stage, training, represents an intermediate learning stage. The learner understands the fundamentals of a topic and only needs a brief overview of the procedure by the teacher. Certifications, in-house training, corporate universities, seminars, and short courses could be classified as stage two methods.

In the third stage, self-training, the self-learner is able to learn in isolation, perhaps from books, monographs, webinars, professional magazine articles, white papers, or product bulletins. The learner then self-tests for competence and applies the methodology to offer a solution. In independent learning, the topics are chosen by the student, and they evaluate their own proficiency.

In the fourth stage, rather than learning what others have discovered, the individual creates and defends the validity of new knowledge and procedures. A PhD symbolizes a student reaching stage four in an educational setting. Supervisors coach employees toward this level of learning proficiency, after which an employee would likely ascend to a senior technical position. These titles do not mean that they know everything, but that they know how to create novel and valid methods, ideas, and work.

As a final classification of learning environments, pedagogy is the art of best practices related to teaching dependent personalities (14). In contrast, andragogy is the facilitation of learning for adults. Adults are often self-directed learners who further their education through resources like post-graduate seminars and short courses. Heutagogy, equivalently named autodidacticism, is related to self-taught learners.

Students work within the pedagogical environment, and teachers and professors are taught to be instructors by the best science and art of pedagogical methods of teaching dependent personalities. The andragogical environment is useful and comfortable as a transition. The self-learning environment of independent learners is quite different, and the transition to it is a leading cause of the gap.

Addressing the gap

After seventeen years in school and functioning within a dependent-learner culture, crossing the gap requires an effort by the individual. Other stakeholders can facilitate the transition, but variation in personalities and readiness to change will mean there is not a one-size-fits-all solution.

What can employers do? Supervisors of new employees need to understand the environmental differences between college and the workplace to identify the student’s perspectives and behaviors and clearly articulate why change is required.

Training seminars and short courses can help the transition. Learning situations that follow the pedagogical model may be easy for teachers and comfortable for students. Still, memorizing facts about the gap is different from changing one’s perspective and behavior. Therefore, employees should use what they have learned about the gap to take deliberate actions to help their transition.

Employers can coach new employees through the transition. Like coaches, employers introduce new topics and concepts, and they observe as team members practice. They help the individual understand what they did right and what they did wrong. Coaches shape the environment so that players feel safe to change and adapt. Supervisors need to understand their role as transition coaches. It takes time to understand and be able to articulate the cultural issues. Here are some ideas that could help employers empathize with and guide young professionals into being productive and experienced team members:

- Have informal, semi-regular sessions with new employees, one-on-one or as a group, to talk about what they are struggling with, what they can improve on, and what they need from management to reach their maximum productivity.

- Be prepared to coach young workers through all aspects of the transition. They are learning new behaviors and social dynamics that go beyond the acquisition of new skills, as well as how their work impacts others.

- Create or join groups that assist academia with workforce development. These groups often fund and guide projects designed to prepare students for hiring needs. For academia, industry-driven projects lead to publications, graduate funding, degrees, and academic stature. For industry, such projects lead to innovative solution methodology, workforce development, and useful knowledge.

- Host evening seminars and field trips for student organizations and discuss with students the culture and expectations they will be introduced to in industry.

- Include graduate students and faculty in summer internships and co-op programs in addition to undergraduate programs so they can understand your workplace technology and culture.

- Support training seminars and workshops for faculty to inform them of industry’s needs. The industry-sponsored AIChE faculty workshop is an excellent example. (More information on these workshops can be found at www.aiche.org/giving/events/ccps-faculty-workshop.)

- Create and publish challenge problems in plant design and unit operations lab courses.

- Mentor student contests such as the Chem-E-Car Competition and provide development feedback on student presentations. An employer’s professional insight about safety, team success, use of resources, and presentation skills will be valuable.

- Encourage, reward, and recognize employees who work with academia in workforce development activities.

- Relay your insight about the cost impact of the gap at the legislative level and on departmental and college industrial advisory committees. Convey your willingness to support academic programs that create employment-ready graduates. Provide a rationale to those directing education to support innovation to bridge the gap. This could include funding pilot-scale equipment in the unit operations lab, hiring and valuing professors of practice for the capstone courses, faculty training courses, etc.

- Initiate or participate in task forces within industrial associations. Be sure to include faculty so that solutions are implementable.

- Help the academic community and affiliate organizations measure the quality of undergraduate programs based on their ability to adequately prepare graduates for the workplace. The Accreditation Board for Engineering and Technology (ABET) provides assessments of the quality of nearly every program in the U.S. Industry representatives have a voice in the accreditation process. It is relatively easy to assess students’ skills and knowledge, and preparation to cross the gap could be included.

What can new employees do? New employees have the greatest incentive to cross the gap and the greatest control over whether they do so. Learning continues to be important after graduation, but the general accumulation of knowledge is not the priority. Some engineers are satisfied memorizing institutional knowledge from the experts — the operators, other engineers, and managers. However, such legacy knowledge often includes outdated rules from prior versions of the process, rationalizations to mask prior nonsuccess, or pre-computer expediencies. Novices can acquire institutional knowledge quickly, and accepting such information conveys the appearance of rapid learning. It allows a novice to appear deliberate, compatible with the team, effective, and credible. Still, young professionals should make sure that what they learn is grounded in fundamentals.

Another expedient approach is to find trends in data using the contemporary — and effectively promoted — magic of big data and machine learning. This convenience finds correlations, but correlation is not causation.

Self-guided learning and the self-validation of knowledge are essential for professional development and personal growth. Oftentimes, your company and supervisors cannot supply you with the knowledge you need. Here are a few pieces of advice to help you become your own teacher (3).

- Have expectations about the implications of an equation, rule, theory, or procedure. If it is right, what do you expect to see and not to see?

- Don’t uncritically accept a procedure, recipe, formula, or rule. Be able to express cause-and-effect mechanisms explicitly and quantitatively.

- Test your understanding of cause-and-effect phenomena by creating your own exercises. Explore alternative examples, numerical values, assumptions, and the inverse relation. Be sure that the relationship between input variables, modeled coefficient values, and output trends is valid.

- Seek knowledge from product bulletins, handbooks, trade magazines, vendor’s white papers, and the internet. Textbooks could be a useful source, but they may be too oriented around math and science fundamentals to have the implementation guidance you need.

- Be your own devil’s advocate. Seek out the perspective of those who could claim to have an alternate opinion about the subject, whether it be from different parts of the company like maintenance, purchasing, and operations, or from other interest groups like opposing communities, politicians, scientists, etc. Consider what aspects they might find desirable or undesirable.

- Accept your new knowledge on a tentative basis. You created it and want to use it to demonstrate your value. It may be difficult for you to see its inadequacy.

- Consider and report the uncertainty in any value. If there is uncertainty in the givens, coefficients, or models, how do these affect the uncertainty of the output value? How does uncertainty on the application impact a decision?

- Be proactive and create a network of mentors. A mentor can act as a coach who guides your induction into an industrial setting and culture, and they are a proven resource for technical information.

- Learn the organizational culture and work to adapt to this new setting. In the industrial workplace and community, technical topics usually dominate learning concepts. Still, soft skills like communication, interpersonal interaction, and workplace customs are at least as important for contributing to engineering effectiveness. Seek to grow in all areas.

What can academia do? Education does an excellent job of equipping students with fundamentals and meeting accreditation criteria, but it could do a better job of preparing students for their transition to lifelong, self-directed, and self-evaluated learning. The following list includes some techniques for professors — especially those who teach capstone and seminar courses — as well as for student extracurricular advisors to help bridge the gap (15–18).

- Design course exercises to have students frequently work in the higher levels of Bloom’s Taxonomy.

- Let students know why lifelong learning is important and how the rules of the game will change after they graduate. Ask seminar speakers to share their experiences about crossing the gap.

- Explain aspects of the gap to your students. Help them understand how their learning patterns that are shaped for pedagogical success will have to change to meet the requirements of their future workplaces.

- Occasionally require students to validate their problem solutions and let them grade their own efforts based on provided specified criteria like quality, completeness, credibility, and communication.

- Periodically require the students to create their own homework exercises. Give them the topics and the learning and validation objectives that their exercise should address. Give grading feedback relative to how well their construct met the learning and validation objectives of the exercise.

- Share with the students your learning objectives for exercises that you create or select. After they complete the exercises, ask them to evaluate your exercises’ effectiveness and how well they meet those objectives. Depending on how individual students react, you’ll initially get responses that range from pandering to useful to angry. Provide feedback to the writers that reveals you want honest, fact-based, and comprehensive evaluations. Create a psychologically safe environment for students to provide honest comments. In the author’s experience, by the end of the course, students became effective partners in the course’s development.

- Include instructors with practice experience in unit operations labs (UOLs) and plant design courses.

- Assign projects that require open-ended innovation rather than the demonstration of skill in a classroom task. For example, assign make-it-better UOL projects, in which they need to design experiments to acquire data to model the unit operation, validate the model, then use the model to define operating conditions that best minimize waste or energy, maximize throughput or robustness to disturbances, or resize some element. However, don’t give them an experimental plan to collect data and the equation from which to generate a value such as a heat transfer coefficient.

- Seek research collaborations with industry.

What can accreditation agencies do? Starting in 2000, ABET began transitioning to require programs to evaluate the quality of graduates based on how their graduates’ employers rate quality, and ABET requires an institution to continuously improve. Still, it is difficult to acquire strong data from employers related to personnel performance, and it is even more difficult to collect data on graduates of a particular school. Therefore, some of the student outcome ratings are based on easily measurable student evaluations such as the FE exam, starting salary, the fraction employed, acceptance to graduate programs, survey opinions from college deans, or alumni surveys conducted by the program. It is hoped that ABET can help devise methods for employer feedback and share best practices with all programs. ABET recently revised student outcome requirements to include complex problems and plant or equipment design assignments that include constraints.

What can professional societies do? Professional societies play a unique role with regard to the gap as students interact with these institutions throughout their transition from education to the workforce. Societies are a source of academic and industrial resources, discipline-wide coordination and advocacy, and professional networking. Therefore, professional societies are in a useful position to address the gap.

- In both professional and student chapter conferences, develop programming sessions that address the gap and potential solutions. Perhaps use panel discussions that include faculty, industrial employees with at least five years of experience, and industrial supervisors of engineers.

- Organize collaborations between practitioners and faculty to develop educational materials. These could include texts, problems, problem-solving methodologies, programming environments, and case studies.

- Provide information to help new graduates cross the gap with articles in magazines, websites, blogs, newsletters, or conference sessions.

- Solicit articles for periodicals, for which there is a large academic readership, relating the experience of those who have transitioned across the gap to encourage a national conversation about the needs of students, employers, institutions, and educators.

What can government agencies do? If the cost to society for chemical engineering graduates to bridge the gap is about $320 million per year in the U.S., consider what it is for all engineering graduates. Imagine the amount of lost productivity when all new college graduates are considered. Federal and state governments are major stakeholders in the phenomena, and they can also facilitate bridging the gap.

- Sponsor development of educational approaches and tools that integrate practice experience.

- Investigate education solutions to minimize the impact of the gap. Increase support for graduate research topics that are industry-driven and interactions among academics and industry for workforce development, such as Industry-University Cooperative Research Centers and Engineering Research Centers.

- Support professional societies to provide continuing education and training for faculty regarding the gap and how to help students bridge it.

- Provide incentives for universities to integrate professors of practice into the curriculum, as well as incentives for industry to collaborate with academia and host internships.

- Initiate activities to determine how to assess the ability of academic programs to produce workforce-ready graduates.

In conclusion

To begin addressing the gap, all parties involved must understand it. Bridging the gap begins by understanding that learning shifts from instructor-led to self-led. While learning remains important, the goal is to bring projects and ideas to fruition. The student-to-professional transition requires one to let go of academic incentive structures and behaviors more suited to the school environment.

In industry, it is best not to accept “knowledge” that might be technical folklore or correlation. Be your own authority, and provide the mechanistic cause-and-effect explanation behind the functions you perform.

While students are still in university, faculty can prepare them for the transition by providing awareness of industry’s culture and rules. Although this alone cannot undo 17 years of a student’s education from the best pedagogical practices, it can help to deliver industry-ready graduates.

Other routes students and employers can take to facilitate the transition are internships and co-op programs, which should be promoted by both industry and academia. Supervisors should recognize that new employees need to be coached through the transition, as entering the workplace with its different culture and expectations can be an unprecedented challenge in a young engineer’s life. Affiliate institutions such as accreditation, professional societies, and governments can also help through the many mechanisms discussed previously. Still, the greatest control of the transition is in the hands of the new employee, but they cannot be expected to do it alone. Everyone involved must work to bridge the gap.

Acknowledgments

The author greatly appreciates the input on this article by Randy Lewis, Sundar Madihally, John O’Connell, Emily Petruzzelli, Colby Kaimanu Tinsley, and Atanas Serbezov. But, of course, if the reader detects any nonsense, it is the author’s.

Literature Cited

- McMillan, G. K., and R. R. Rhinehart, “The Real Deal with Control Education,” CONTROL, 33 (11), pp. 46–48 (Nov. 2020).

- Parrillo, D., et al., “The Importance of Industrial/Academic Sponsorship of Industrial Internships — A Case Study on Digital Internships to Facilitate Dual Domain Skills in the STEM Field,” Chemical Engineering Education, 57 (3) (June 28, 2023).

- Rhinehart, R. R., “Bridging the Gap — The Problem,” CONTROL, 28 (4), pp. 18–22 (Apr. 2015).

- Rhinehart, R. R., “The Solution,” CONTROL, 28 (6), pp. 14–16 (June 2015).

- Rhinehart, R. R., “The Industrialization of a Graduate, Part I: The Business Arena,” Chemical Engineering Education, 21 (1), pp. 18–22 (Winter 1987).

- Rhinehart, R. R., “Methods for Engineering Education,” Chemical Engineering Education, 21 (2), pp. 68–71 (Spring 1987).

- Rossiter, A., et al., “A Survey of International Views on a First Course in Systems and Control for Engineering Undergraduates,” IFAC Journal of Systems and Control, 13, pp. 1–15 (Sept. 2020).

- Alger, M., et al., “Digitally Coupled Learning and Innovation Processes,” Industrial & Engineering Chemistry Research, 58, pp. 22445−22455. (Sept. 3, 2019).

- American Institute of Chemical Engineers, “Chemical Engineering Academia-Industry Alignment: Expectations about New Graduates,” AIChE, New York, NY (Nov. 1, 2015).

- Institute of Education Sciences, “Degrees in Chemical, Civil, Electrical, and Mechanical Engineering Conferred by Postsecondary Institutions, by Level of Degree: 1970–71 Through 2014–15,” National Center for Education Statistics, Washington, DC (2016).

- “2023 AIChE Salary Survey Results,” Chemical Engineering Progress, 119 (5), pp. 21–31 (June 2023).

- Armstrong, P., “Bloom’s Taxonomy,” Vanderbilt Univ. Center for Teaching, Nashville, TN (2010).

- Rhinehart, R. R., “How to Guide Your Lifelong Learning,” CONTROL, 34 (6), pp. 59–61 (June 2021).

- Heick, T., “Pedagogy, Andragogy, and Heutagogy,” Center for Online Learning, Research, and Service, Springfield, IL (Oct. 10, 2015).

- Hess, D. W., “Improving Team Effectiveness Through Psychological Safety,” Chemical Engineering Progress, 119 (10), pp. 35–39 (Oct. 2023).

- Rhinehart, R. R., “How to Be Your Own Professor,” CONTROL, 30 (3), pp. 69–70. (Mar. 30, 2017).

- Rhinehart, R. R., “Preparing Students for Lifelong Learning,” Chemical Engineering Education, 53 (2), p. 130 (2019).

- Felder, R. M., “The Generic Quiz: A Device to Stimulate Creativity and Higher-Level Thinking Skills,” Chemical Engineering Education, 19 (4), pp. 176–181, 213–214 (Jan. 1985).1

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.