(624g) Continuous Manufacturing Platform for Ribonucleotide Triphosphates (NTPs)

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Pharmaceutical Discovery, Development and Manufacturing Forum

Continuous Processing: Next Generation Advancements

Wednesday, November 8, 2023 - 5:36pm to 5:57pm

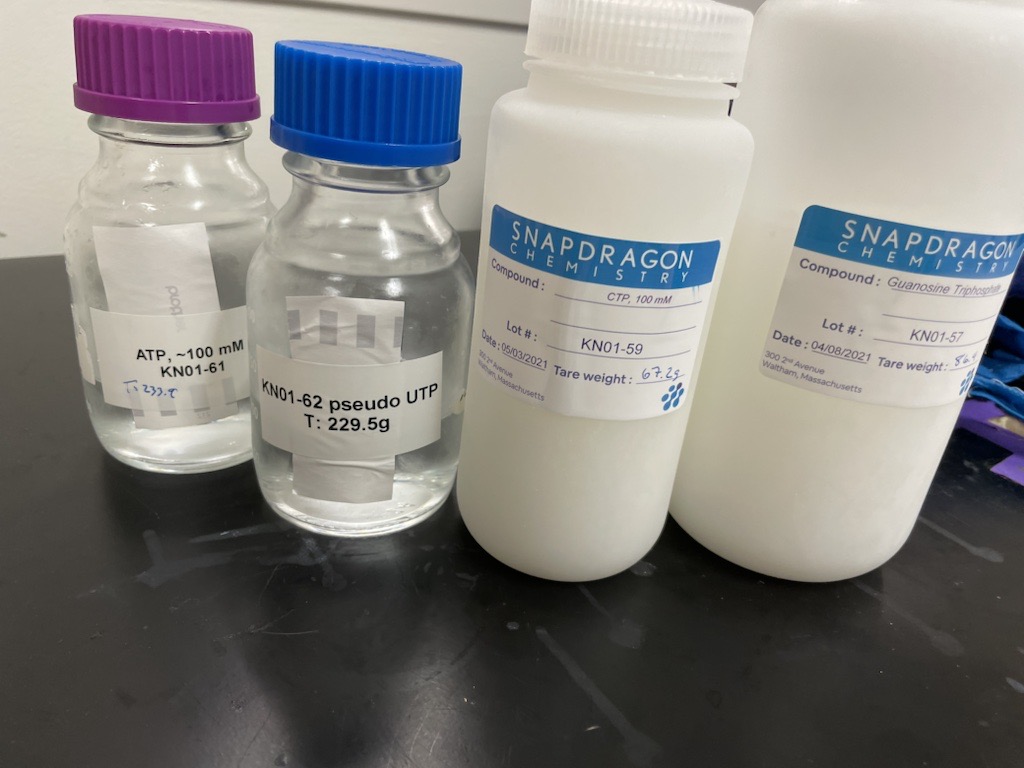

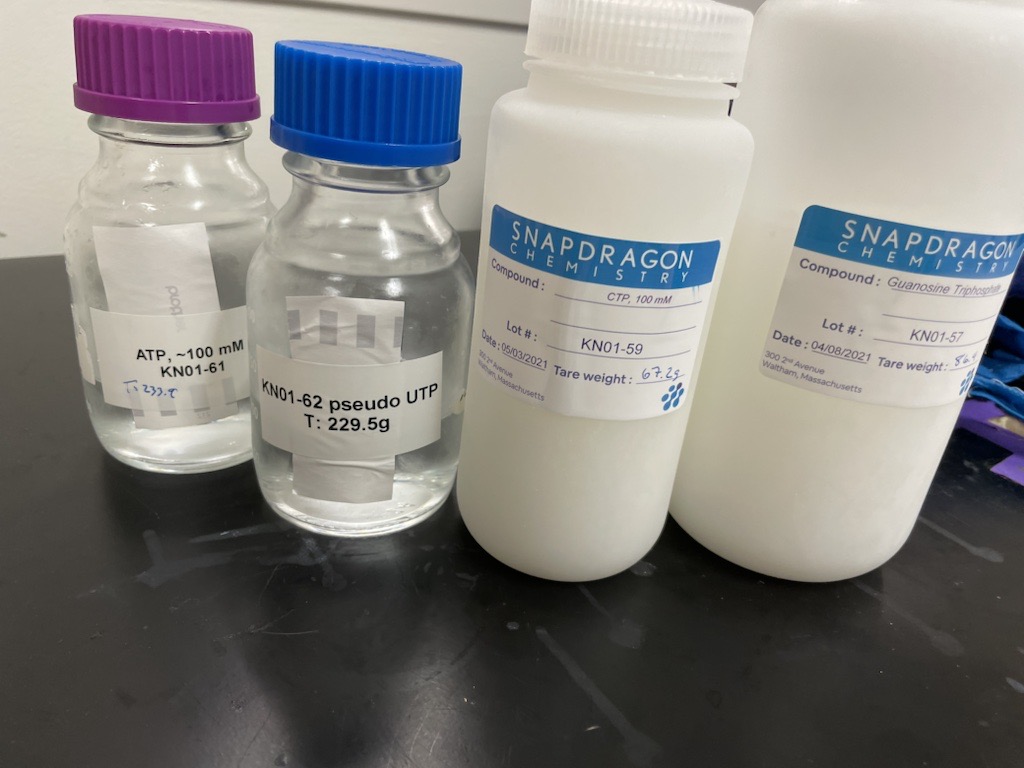

mRNA vaccines have grown to be tremendously important since the COVID pandemic started in 2020. As part of a grant with BARDA, we developed a platform for the manufacture of synthetic nucleoside triphosphates (NTPs), the key raw materials used in the synthesis of these RNA based vaccines. The manufacturing approach uses low cost, fungible feedstocks with a small footprint while requiring low capital investment. Commercially unavailable raw materials required for NTP synthesis were manufactured in-house using continuous reaction and workup technologies, including catch-and-release chromatography and wiped film evaporators. The crude NTPs were manufactured from a nucleoside, such as guanosine or adenosine, using an integrated multistep flow reactor system. The resulting products were subsequently purified to give >97% purity. All four canonical bases as well as psuedouridine were synthesized using this platform, and the resulting NTPs were used to synthesize mRNA. In this presentation, we’ll provide an overview of the manufacturing platform as well as how automation and PAT were incorporated in order to generate a scalable, robust, manufacturing platform for these important materials.