Materials and Chemicals

Heat Transfer Fluid Features Wide Operating Range

Globaltherm Q is a synthetic organic heat transfer fluid that displays high thermal stability, efficient heat transfer capability, and reliable performance. Formulated with a precise blend of diphenylethane and alkylated aromatics, Globaltherm Q offers a wide temperature operating range of –35°C to 330°C. This versatility makes it suitable for heat transfer systems requiring both low-temperature pumpability and high-temperature stability. Additionally, this formula features an extended operating life and can operate under low-pressure conditions, minimizing system wear.

Global Heat Transfer

Waterborne Alkyd Portfolio Improves Sustainability Efforts

Neptem for alkyds is a portfolio of emulsifier solutions comprised of low-volatile organic compound (VOC) waterborne alkyds. With the goal of reducing carbon and VOC emissions, the portfolio enables the creation of sustainable resins without dropping performance capabilities. The waterborne alkyds match or exceed the quality of traditional solvent-based solutions and have broad formulation applications with varying oil lengths. Technical support is also available with the product to provide customers with a smooth transition and formulation assistance.

Perstorp AB

Pyrolysis Oil Products Improve Product Quality

Pyrolysis oil is derived from plastic waste and requires upgrading and purification before it can be used as a feedstock in steam crackers or refineries. The Purocel suite of products and catalyst technologies is formulated to improve the quality of pyrolysis oil, driving greater circularity for plastics and reducing the concentration of chlorides, silicon, total acid number (TAN), and other contaminants. The series includes adsorbents, rejuvenated hydrotreating catalysts, and a modular polishing skid, expanding the company’s line of pyrolysis oil products.

Evonik Industries AG

Cleaner Is Suitable for Food and Beverage Plants

The DART 151 X-R is a cleaning formulation that penetrates and removes stubborn films, oxides, milkstone, scale, and other soils from food and beverage processing equipment. Made of a concentrated blend of acids and surfactants, this formula exhibits moderate to high foam characteristics and can be applied by manual, foam, or immersion methods. It is acceptable for use in food and beverage plants as an A3 acid cleaner and is suitable for applications in the food, beverage, and dairy processing industries.

Madison Chemical

Biodegradable Polymer Can Reduce the Environmental Impact of Disposable Products

Hygiene products, such as wet wipes and sanitary pads, contribute to large-scale environmental problems, including sewer blockage, microplastics accumulation, and pollution. Hydropol is a water-soluble, marine-safe, non-toxic polymer for use in hygiene products. The polymer can replace traditionally used plastics in a newly developed, dissolvable, nonwoven material that is composed of biodegradable fibers. When flushed, the fibers absorb water and swell, rather than fragment into microplastics, in addition to repelling toxins from their surface to prevent drain blockages. This nonwoven technology also has diverse applications outside of hygiene products, including insect repellent, makeup remover wipes, and industrial wipes, giving it the potential to significantly reduce waste.

Aquapak Polymers

Reformulated Pigment Blend Excludes Common Harmful Substances

The trimethylolpropane (TMP)- and trimethylolethane (TME)-free TIOXIDE TR81 grade is the first in a series of reformulated titanium dioxide (TiO2) pigments. While TMP and TME are commonly added to pigments for surface treatment, they have been classified as suspected reproductive toxicants and carcinogens. Designed to meet stricter chemical regulations, the new pigment delivers the same opacity, brightness, dispersibility, and durability as its predecessor. By replacing TMP with different organic compounds, customers can seamlessly meet compliance requirements without compromising product performance.

Venator Materials PLC

Operations and Maintenance

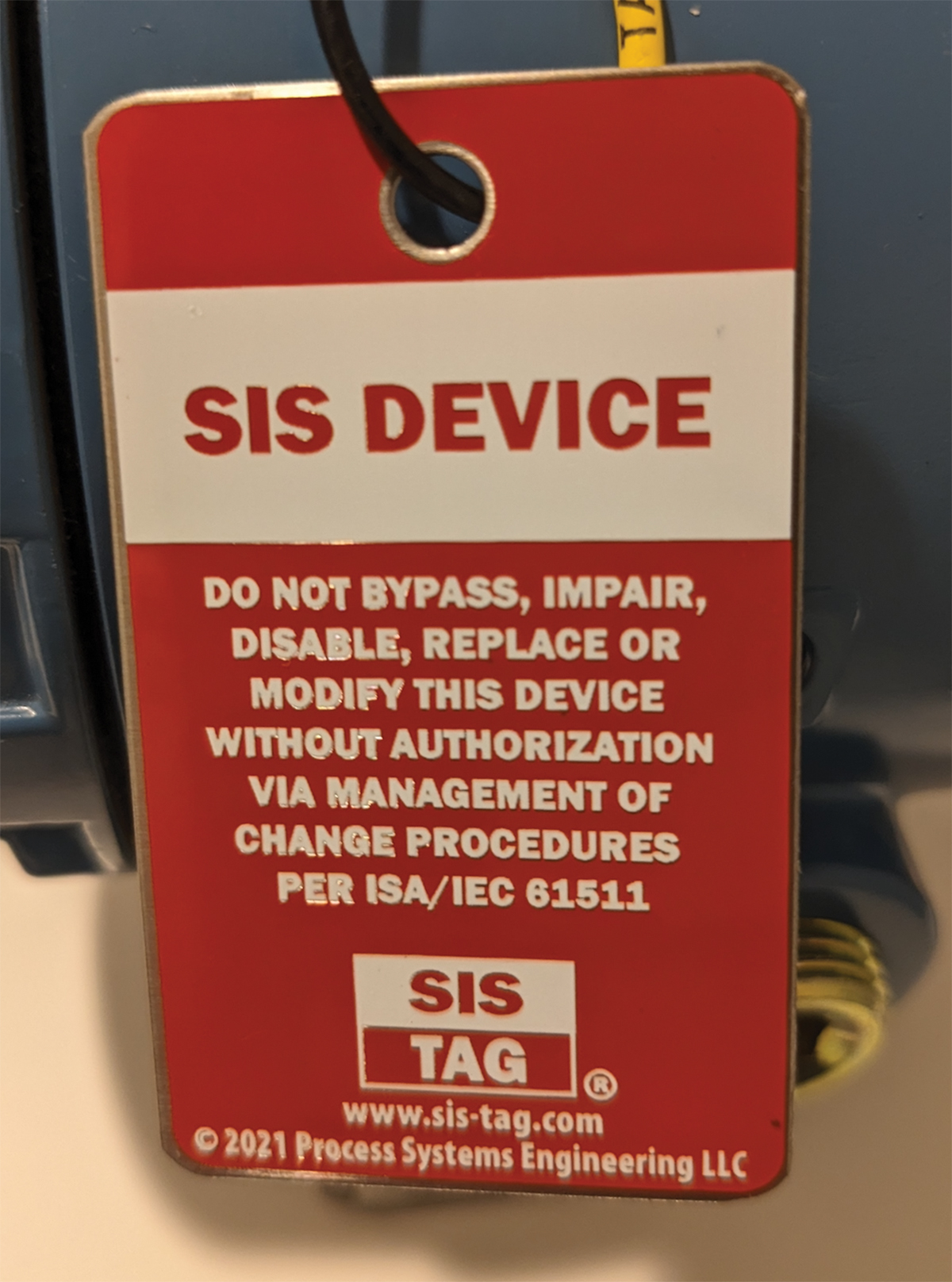

Identification Tags Are Constructed of Stainless Steel

Identification tags are used across industries to provide high visibility and effective asset management of safety-critical devices, particularly in harsh environments as they resist degradation and fading of text and color in direct sunlight. This manufacturer’s safety instrumented system device identification tags are now available in stainless steel for long-term durability in the chemical process industries (CPI). These tags are available in a variety of sizes and color combinations and can be customized to feature text and QR codes.

Process Systems Engineering LLC

Industrial Camera Series Include Multiple Mounting Options

The uEye Live SCP and SLE camera series allow for the streaming, monitoring, and event recording of industrial processes. The SCP series is entirely enclosed within a 29×29×29-mm housing, while the SLE series consists of board-level models for embedded applications with different mounting options. Both feature event-based recording in the camera’s memory, which means that data is stored when triggered by an incident. These cameras are designed for standalone operation and provide users with video streaming and hardware-accelerated video encoding capabilities.

IDS Imaging Development Systems GmbH

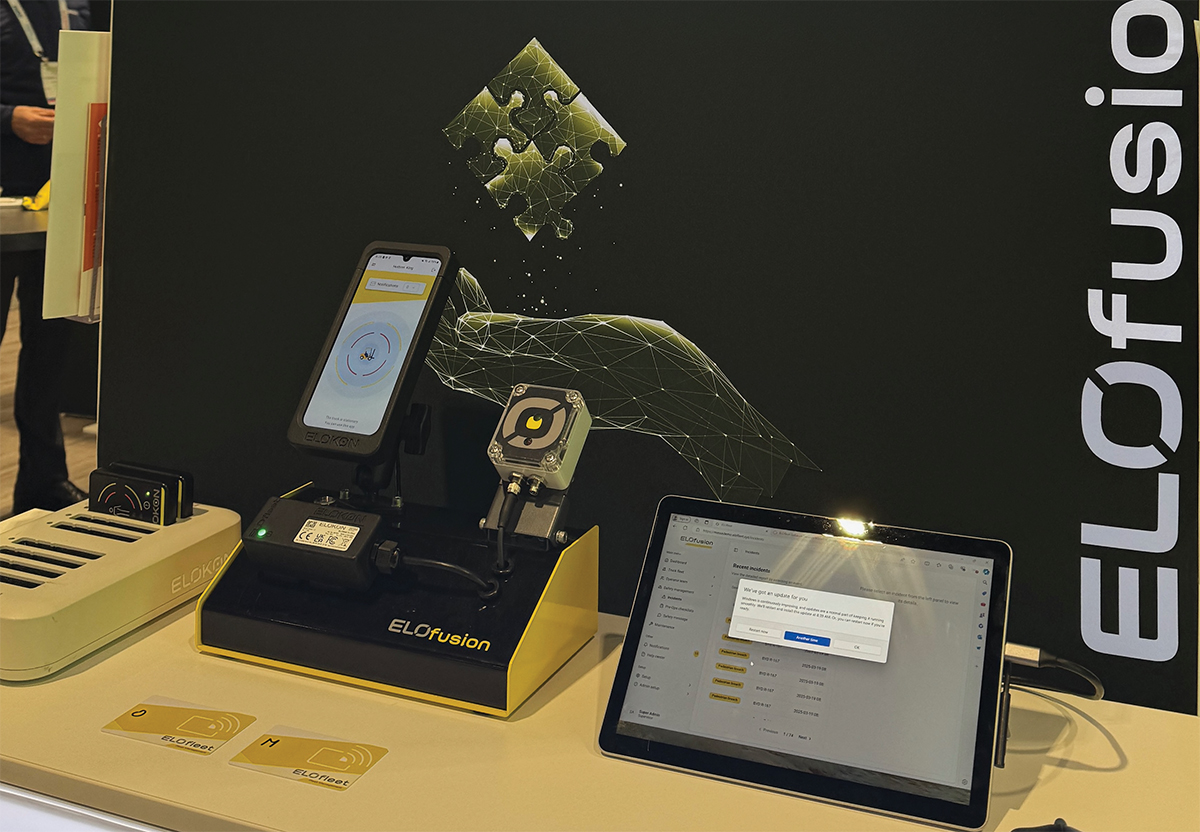

Forklift Safety System Helps Detect and Avoid Obstacles

ELOfusion is an integrated hardware and software solution designed to help improve forklift safety. The system uses ultra-wideband (UWB) radio waves to gauge the distance between the forklift and surrounding objects. Its precise detection mechanism can penetrate obstacles without triggering false alarms and simultaneously manage multiple pedestrian detections. The system features intelligent speed adjustment in danger zones such as doorways or confined spaces; comprehensive fleet management features like radio-frequency identification (RFID) access control, impact sensors to detect violent damage, and more; and centralized data analysis through the ELOfleet.com platform.

ELOKON Inc.

Instrumentation

Photoelectric Sensors Are Designed for Compact Automation Applications

Increases in the ubiquity and complexity of automated systems have driven a demand for smaller and lighter sensors. The SA1N photoelectric (PE) sensors are subminiature devices designed for automation applications requiring reliable and accurate readings. This line includes two versions: a barrel-mount, fiber-type, diffuse-reflective, infrared LED style, secured with M6 nuts through a mounting hole; and a block type, convergent-reflective, red LED style, secured with two mounting holes located at a 14 mm pitch. Both versions are all-in-one devices with built-in amplifiers and sensitivity adjustment control. The barrel-mount version has a 3–50-mm sensing range, while the block type has a sensing range of 5–30 mm.

IDEC Corporation

Four-Axis Robot Advances Automation Efficiency

The DR1000 four-axis delta robot is a precise, high-speed tool that can pick up and place items in industrial settings. The robot includes a 1,000-mm working diameter with an additional rotary axis, providing the machine with four degrees of freedom. With a pick rate of 96 picks/min, the DR1000 is ideal for pick-and-place applications, conveyor belt picking, or three-dimensional stacking tasks. For maximum user-friendliness, the robot’s modular design allows it to be easily integrated into existing automation systems. Add-ons and further customizations are also available to meet each customer’s needs. Users can install the robot control (iRC) software or use their own systems, which allow each axis to be operated with individual motor controllers for optimal control.

igus GmbH

Manufacturer Expands Its Hygienic Valve Portfolio

The newest additions to the manufacturer’s line of hygienic valves include the Unique safety shutdown (SSV) pressure relief valve, a leakage detection butterfly valve, and smaller sizes of the Unique Mixproof clean-in-place (CIP) and Unique Mixproof process valves. These additions provide greater flexibility while maintaining safety and product integrity. The Unique SSV pressure relief valve protects hygienic processes, especially those with positive displacement pumps, from overpressure with easily adjustable pressure relief setpoints and integrated ThinkTop technology for heightened monitoring and control. The leakage detection butterfly valve features a lightweight and compact design and leakage detection software for rapid response. The wider range of valve sizes increases users’ ability to tailor process valves to their process’ needs.

Alfa Laval

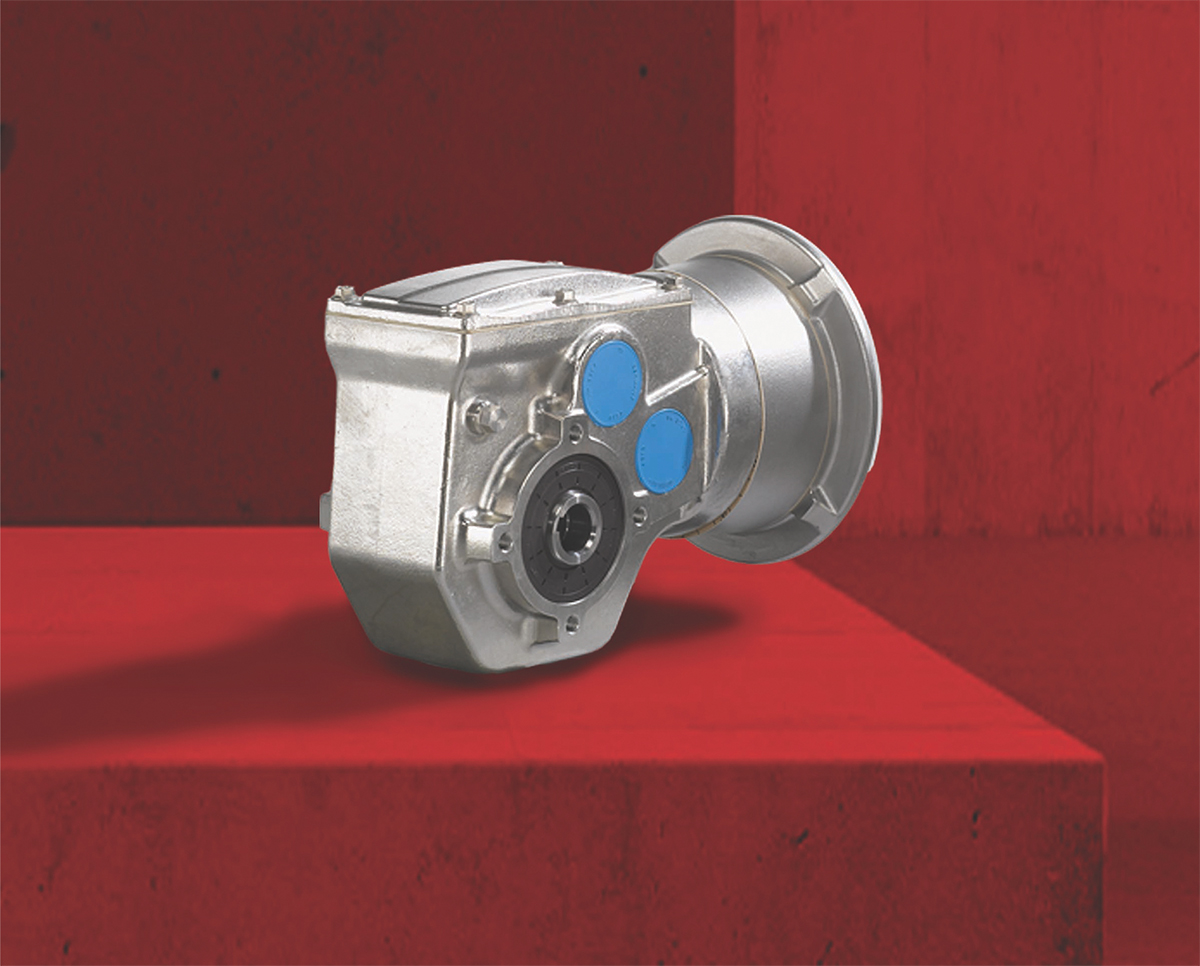

Gear Unit Eliminates Heating in Transmission Applications

The WES series stainless steel gear unit converts motor output to the appropriate speed and torque required for hygienic applications such as food and beverage, pharmaceutical, and chemical processes. This compact and hygienic unit runs cool, even under continuous operation, eliminating hygiene risks and the need for a cooling fan. The integrated SPIROPLAN gearing technology minimizes friction, reducing heat compared to warm gear units and eliminating burn hazards. The construction is durable and washdown-ready, and the smooth surface reduces contaminant buildup.

SEW-EURODRIVE GmbH

Integrated Dewpoint Sensor Enhances Reliability in Gas Processes

The AVENTICS DS1 sensor monitors dew point, temperature, humidity, and air quality with a single device. The device can be used to help operators detect excess moisture early, which is essential for protecting equipment from moisture-related damage. This also allows for better process control, regulatory compliance, and maintenance reduction. The sensor can be easily integrated into existing systems — allowing users to place the sensor close to the process, rather than at the site of compressed air generation, for accurate data measurement — and connects to networks via Modbus transmission control protocol (TCP).

Emerson Electric Co.

Ultrasonic Flowmeters Feature Digital Signal Processing Technology

The M-2300 Series of high-purity, inline, straight-tube, ultrasonic flowmeters integrate advanced digital signal processing (DSP) technology, as well as an inline ultrasonic flow sensor and electronics into a single compact unit. These units feature a straight-through perfluoroalkoxy (PFA) tube that delivers ±1% accurate and ±0.5% repeatable readings with minimal pressure loss. Units are available in 1/4 in., 3/8 in., and 1/2 in. tubes and fittings. These flowmeters are suitable for various semiconductor applications, including cooling systems, electroless deposition, laser equipment, solar photovoltaic (PV) equipment, and more.

PSG

Contactor Series Is Designed for High Continuous Currents

The latest version of the Eddicy C303 contactor series is capable of handling continuous currents up to 500 A and has earned certification from Underwriters Laboratories (UL), CE, and UKCA. This device was designed to support applications with greater power needs, such as energy storage systems, fast-charging stations, test benches for batteries, and large-scale industrial electrification projects. The contactors offer lower total cost of ownership (TCO) through enhanced efficiency and durability. Features such as ultra-low contact resistance minimize power losses and heat generation, while robust design elements extend the operational lifespan.

Schaltbau

Environmental, Health, and Safety

Portable Emergency Spill Kit Promotes Workplace Safety

These portable emergency spill kits are compact caddies that can be used to consolidate spilled materials, helping avoid equipment damage and reduce repair costs. Now available in a high-visibility yellow, the caddies contain sorbet mats, gloves, safety goggles, and other safety-related equipment. Contained in a lightweight, compact, wheeled design, the caddies can be easily maneuvered for quick incident response and are neatly organized for ease of operation. The lockable spill caddies comply with Occupational Safety and Health Administration (OSHA) and U.S. Environmental Protection Agency (EPA) regulations. The small- and medium-sized caddies can absorb up to 55 and 100 gal of fluid, respectively, and are available for varying spill classifications.

DENIOS, Inc.

Laboratory Equipment

Fluidized Bed Reactors Are Equipped for Diverse Chemical Processing Applications

Fluidized bed reactors are efficient reactors that can be used in chemical processes where diffusion or heat transfer are key design parameters, such as gas-solid reactions, catalytic hydrocarbon cracking, and waste conversion. The laboratory-scale fluidized bed reactors are available in five different materials of construction to fit different customer needs, including 316 stainless steel and varying alloys. The reactors also feature internal differential pressure measurements, centerline temperature profiles, and compact sizes for enhanced efficiency, and can operate at temperatures as high as 600–895°C and pressures up to 1,000 psi. Additionally, integrated solid, liquid, and gas recovery systems minimize costs and environmental waste.

Parr Instrument Company

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.