Steam-assisted flares can be prone to troublesome issues. Ensuring a high-quality steam supply is an important step in mitigating these problems.

Flare systems are important safety and environmental systems for refining and petrochemical plants, and many of these facilities use steam-assisted flares to protect the flare tip and promote smokeless burning.

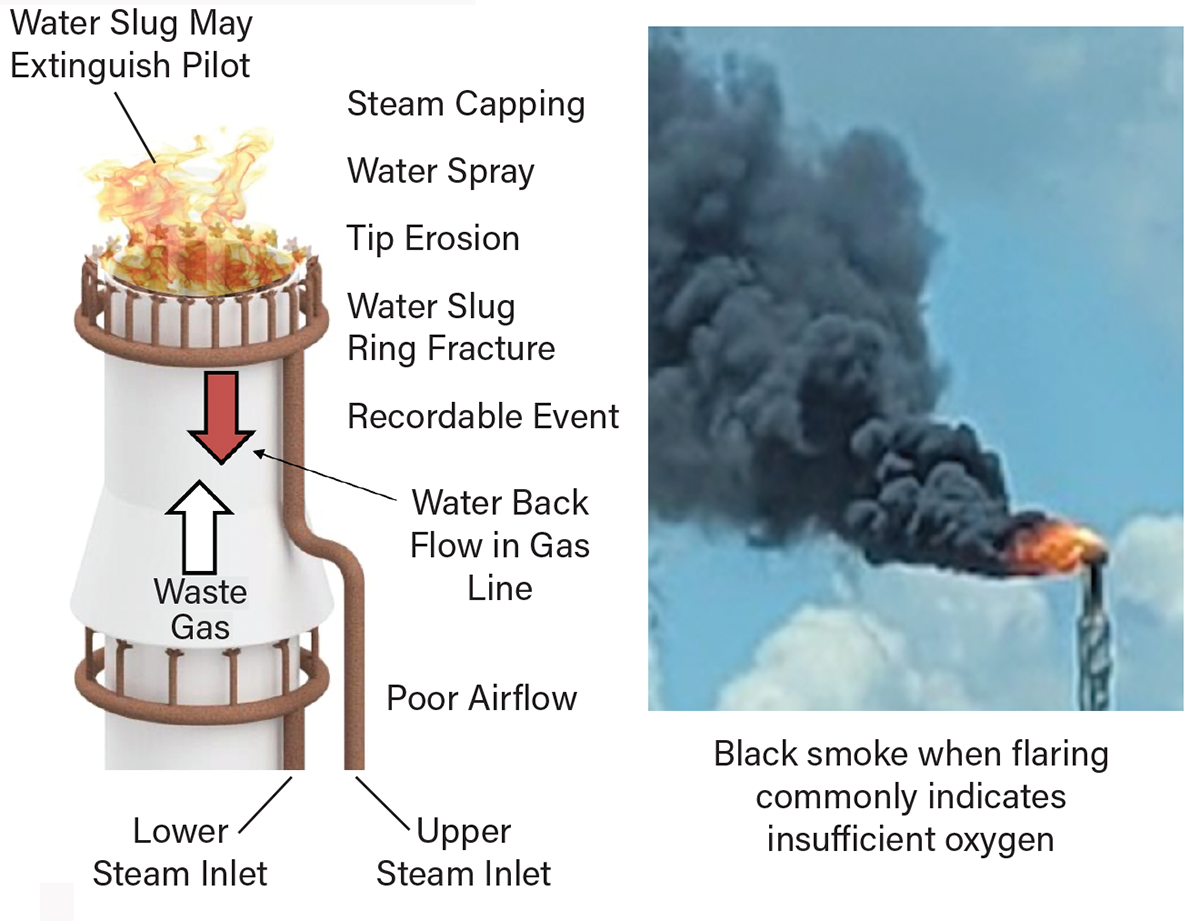

The primary goal of steam-assisted flares is to achieve complete and rapid destruction of the flare gas stream; much supporting design information is available that supports this goal. However, most of these guidelines relate to the handling of the gas stream and not the steam. This is unfortunate, because many reliability issues and incidents can be mitigated by improving the design of the steam system and the quality of the steam that is supplied to the flare (Figure 1).

▲Figure 1. Troublesome issues can occur at multiple locations on a flare system, and condensate can be the cause.

Steam performs a variety of supporting actions that are critical to the overall combustion process. For example, steam promotes air induction and turbulent mixing with the gas stream, increases the waste gas momentum, and provides a more readily combustible mixture to the pilot flame. Steam enables lower temperature burning and facilitates a smokeless exhaust from optimal fuel and air mixing, which mitigates formation of the hot carbon/soot. It also acts as a cooling medium at the tip of the flare, protecting some components from overheating and damage. Even though steam is so important, it is often overlooked, which can lead to the reliability issues shown in Figure 1.

Two common factors that cause flare incidents are slugs from ineffective condensate removal and/or poor quality/wet steam from lack of moisture disentrainment. These two common factors, as well as a few other steam-related issues, can cause a host of problems in flares, such as:

- tip and ring erosion (from slugs or entrained water)

- improper or lack of precise steaming control (generally from slugs)

- flare-outs (caused by slugs)

- tip damage (caused by slugs or entrained water)

- smoke (caused by poor air mixing, poor burn)

- steam capping (caused by excessive steam flow)

- pipe damage (caused by slugs)

- water backflow (caused by poor condensate drainage)

- ring fracture (caused by slugs)

- falling ice (caused by condensate being discharged/pushed through the tips and freezing).

Many reliability issues associated with steam-assisted flares can be mitigated by incorporating some of the recommendations presented in this article, which will help improve the site’s steam system quality.

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.