Heat Exchanger Design and Operations

Heat exchangers are critical to a wide variety of engineering applications –

From power plants to chemical processing facilities. When they go down, you feel the negative impact. Join heat exchanger expert Joseph Holmes or Greg Starks and get up-to-date on the latest developments and strategies in heat exchanger design and the diagnosis, correction and troubleshooting of costly operating problems.

Gain a working knowledge of recent developments

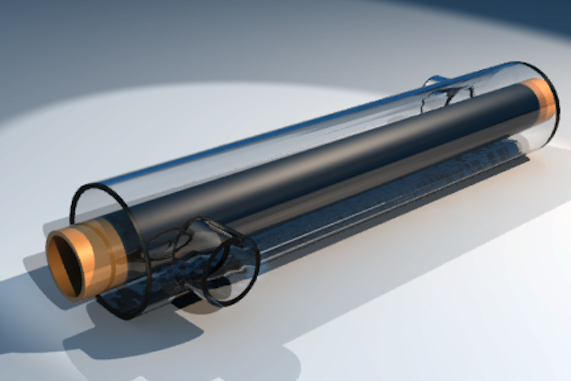

In two days, you’ll examine in detail the design of shell-and-tube exchanger technology – the most common type of heat exchanger in oil refineries and chemical processes – and how to minimize fouling and ensure trouble-free operation. You’ll learn how to efficiently operate other types of exchangers, including gasketed plate, spiral plate and air-cooled equipment. Plus, you’ll learn strategies to help you troubleshoot, diagnose and correct operating problems – including those common to distillation column reboilers and condensers.

By the end of the course, you’ll gain state-of-the-art information and strategies you can apply to ensure the success of your next project involving heat exchanger sizing, specification and operation.

Instructor(s)

| AIChE Members | $1,495.00 |

| AIChE Grad Student Members | $747.50 |

| AIChE Undergrad Student Members | $747.50 |

Horizontal Tabs

Day One

8:00 – 8:30

Registration

8:30 – 10:00

Types and applications of heat exchangers

- Types

- Shell-and-tube heat exchangers

- Air coolers

- Plate-frame exchangers

- Compact plate-fin exchangers

- Applications

- Single-phase

- Boiling/evaporating

- Condensation

10:00 – 10:15

Morning Break

10:15 – Noon

Fundamentals of heat exchanger performance

- Energy balance

- Rating methods

- F-LMTD

- e-NTU

- Incremental computer-based

- Pressure drop

- Performance margins

- Fouling factors

- Cleanliness factors

Noon – 1:00

Lunch Break

1:00 – 3:00

Heat exchanger selection criteria

- Cost

- Operating Conditions

- Transient

- Maintenance needs

- Cleaning schedule

- Material selection

- Fluid compatibility

- Mechanical considerations

- Temperature and pressure

3:00 – 3:15

Afternoon Break

3:15 – 5:00

Single-phase applications

- Heat transfer coefficients

- Pressure drop

- Extended surfaces

- Enhancements

- Tube inserts

Day Two

8:30 – 10:00

Boiling applications

- Boiling fundamentals

- Pool boiling

- Flow boiling

- Two-phase pressure drop

- Typical services

- Refrigerant evaporators

- Reboilers

10:00 – 10:15

Morning Break

10:15 - Noon

Condensing applications

- Condensing fundamentals

- Film condensation

- Condensing regimes

- Pressure drop considerations

- Condenser geometries

Noon – 1:00

Lunch Break

1:00 – 3:00

Operational problems

- Fouling

- Vibration

- Venting and draining

- Reboiler problems

- Instability

- Film boiling

- Temperature pinch

3:00 – 3:15

Afternoon Break

3:15 – 5:00

Troubleshooting

- Use of field data

- Accuracy of measurements

- Accuracy of performance models

- Inspections

- Typical mechanical defects/degradation

Accommodation Instructions

AIChE Group Rate available at LaQuinta Inn & Suites Energy Corridor. Click link above or mention Booking Code AICHE1 to receive group rate (subject to availability). More info