(224d) Cocrystal Formation Using Fatty Acid Toward a Sustainable, Easy and Rapid Pharmaceutical Process

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Engineering Sciences and Fundamentals

Poster Session: Thermodynamics and Transport Properties (Area 1A)

Tuesday, November 7, 2023 - 3:30pm to 5:00pm

Cocrystallization can be applied for the dissolution enhancement of active pharmaceutical ingredients (APIs) in the pharmaceutical industry. Cocrystal, which is the crystal composed of API and other molecules called as coformer, maintains the structure by noncovalent bonds. Cocrystallization can be applied to APIs with no dissociable group. Therefore, the technique has been focused on. While cocrystal formation methods, such as solvent evaporation, liquid assist grinding and cocrystallization with supercritical solvents, can be applied to cocrystallization for many species of APIs successfully, they still have some issues: using organic solvent, including multistep procedures and requiring a long reaction time. In the solvent evaporation [1], APIs and coformers are dissolved into the organic solvent and cocrystal is precipitated by the evaporation of solvent under room temperature. It is easy operation, but it needs a long time to evaporate solvents completely. In the liquid assist grinding [2], a little organic solvent is delivered by drops into APIs and coformers and then the mixture is stirred to form cocrystal. Dropped organic solvent plays a role of medium, in which can lead to enhancement of cocrystallization. It is an easy and rapid process, but it includes an issue that a toxic organic solvent is remained in products. In the cocrystallization with supercritical solvents [3], APIs and coformers are partially dissolved in supercritical CO2, which is used as a cocrystallization medium. Although it is a sustainable method, it remains a problem that it requires a long experimental time to achieve the high purity.

This research aims to develop a sustainable, easy and rapid method of cocrystallization using liquefied fatty acid instead of organic solvent. Fatty acids are harmless materials that have also properties with surfactant [4], which could be interacted with the crystal surfaces of raw materials and promote the mass transfer from the crystal surface of APIs and coformers to the liquid medium. Additionally, focusing on the reduction of viscosity of fatty acid under high-pressure CO2 [5] and expecting the further enhancement of mass transfer, the combination of high-pressure CO2 and liquefied fatty acid was also applied to the cocrystallization medium.

Methods

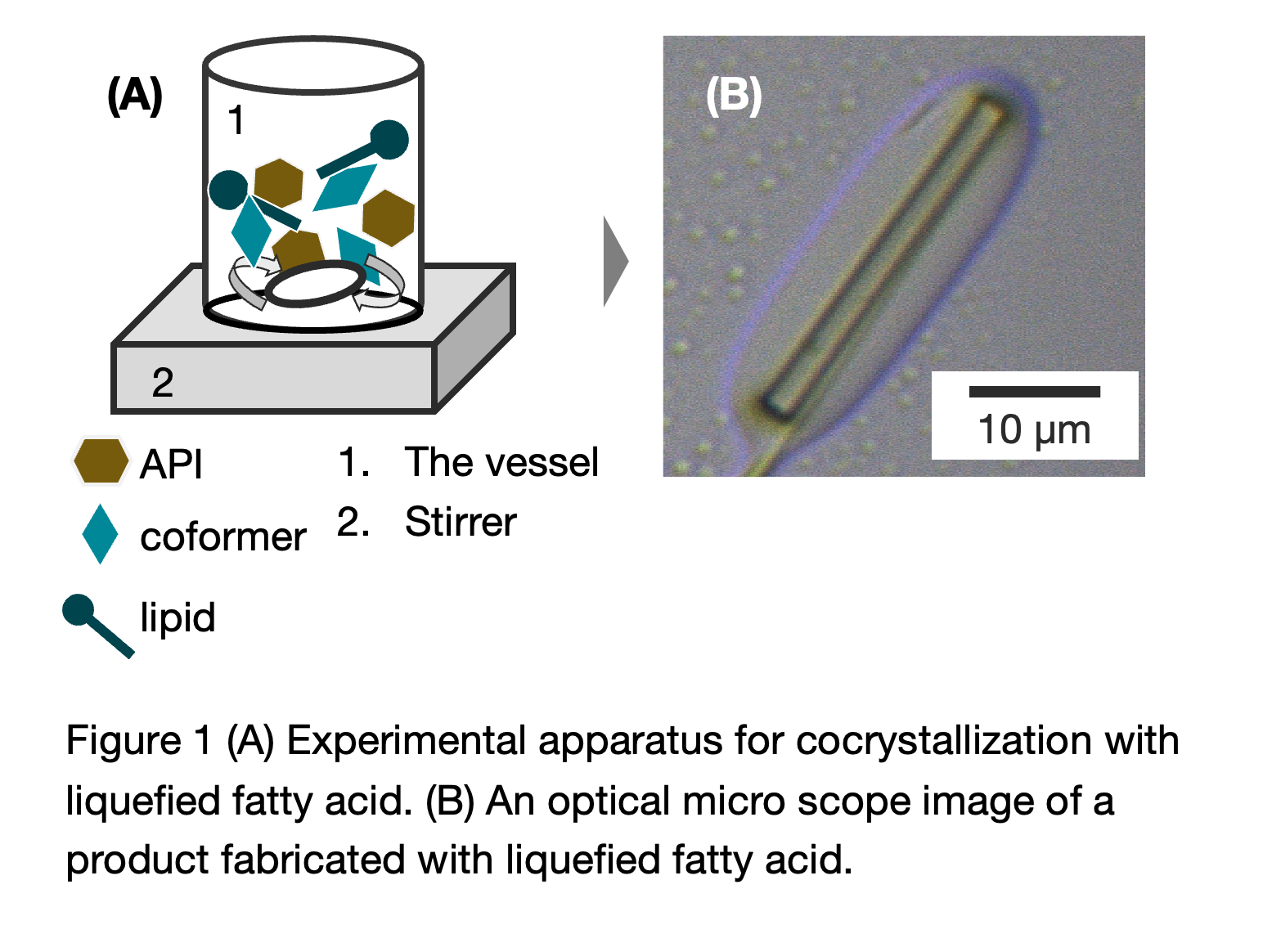

Figure 1(A) shows the apparatus used for cocrystallization under liquefied fatty acid. Theophylline (TPL, 1 mmol) as API and nicotinamide (NA, 1 mmol) as coformer were added to the vessel. After adding linoleic acid (LA, 0.2 or 0.4 g) as fatty acid or 1-octadecene (1-OD, 0.4 g) as hydrocarbon used reference, the mixture was stirred from 1 to 120 min under 22 oC as shown in Figure 1(B). To investigate the universality of proposed method, we applied these procedures to some pairs of API and coformer (TPL (1 mmol) : urea (1 mmol), caffeine (CAF, 2 mmol) : malonic acid (MA, 1 mmol), ibuprofen (IBU, 1 mmol) : isonicotinamide (INA, 1 mmol) and itraconazole (ITZ, 0.2 mmol) : succinic acid (SUC, 0.1 mmol)). In the cocrystallization method using liquefied fatty acid with high pressure CO2, API and coformer were included in the vessel, followed by LA (0.4 g). The vessel was placed into the high-pressure vessel made of sapphire window and carbon dioxide was introduced by the Semi-preparative CO2 pump. The mixture was stirred while maintaining the inside pressure (0.1 or 10.0 MPa) and temperature (50 oC). After 120 min, the vessel was depressurized.

The crystal structure was evaluated by Powder-Xray diffraction (PXRD). Cocrystallization degree was also evaluated as the ratio of the characteristic peak intensity cocrystal to the sum of characteristic peak intensities of API, coformer and cocrystal.

Results & Discussion

To investigate cocrystallization using liquefied fatty acid, the crystal structures were evaluated for products with TPL and NA that were fabricated by stirring with and without liquefied hydrocarbon (1-OD, 0.4 g) and fatty acid (LA, 0.4 g) for 120 min by PXRD. Focusing on the characteristic peak of TPL and NA, TPL:NA showed the biggest peak intensity of the three. On the other hand, focusing on the characteristic peak of cocrystal [6], TPL:NA/LA showed the biggest peak intensity of the three. These results mean that the addition of liquid accelerates cocrystallization and that the carboxyl group of liquefied fatty acid plays a role in enhancing cocrystal composed of TPL and NA effectively. Moreover, from the time dependence results of cocrystallization degree to TPL:NA and TPL:NA/LA with 0.2 g of LA, the values of cocrystallization degree of TPL:NA were much smaller than those of TPL:NA/LA under all reaction time. The cocrystallization degree of TPL:NA was still small value after 120 min whereas the cocrystallization degree of TPL:NA/LA increased rapidly from 10 to 20 min. These results suggest cocrystallization is kinetically improved under LA.

To investigate the versatility of the method using liquefied fatty acid, we selected some pairs of APIs and coformers (TPL : urea, CAF : MA, IBU : INA and ITZ : SUC) and analyzed the role of liquefied fatty acid through the cocrystallization degree. For TPL : urea, CAF : MA and IBU : INA, each of the cocrystallization degree with LA (0.4 g) was bigger than that without LA. The addition of liquid during stirring promotes the mass transfer of raw materials as reported in liquid-assist grinding [2]. Additionally, the carboxyl group in fatty acids may interact with the crystal surface of API and coformer, thereby promoting the mass transfer from their surfaces. However, the combination of ITZ and SUC was not allowed to form the cocrystal with and without LA. It is suggested that the addition of LA is insufficient to promote the mass transfer of ITZ because ITZ has a large molecular size compared to the others. The liquefied medium that promotes mass transfer more increasingly that the liquefied fatty acid may be necessary to achieve ITZ cocrystallization.

To prepare the medium promoting mass transfer strongly, we performed ITZ cocrystallization experiments with liquefied fatty acid whose viscosity is reduced by introducing high pressure CO2. The viscosity of fatty acid is generally reduced under high pressure CO2 by dissolving CO2 into fatty acid [5], which is expected to reduce the viscosity of the medium without causing the thermal denaturation of APIs due to high temperature. As a results, ITZ:SUC_0.1 MPa, ITZ:SUC_10.0 MPa and ITZ:SUC/LA_0.1 MPa did not show any new peaks while ITZ:SUC/LA_10.0 MPa only showed new peaks assigned to the cocrystal composed of ITZ and SUC. From this result, the combination of LA and high-pressure CO2 is a suitable medium to promote mass transfer of ITZ strongly and achieve cocrystallization. Therefore, the medium with LA and high-pressure CO2 can be clearly effective for the cocrystallization.

Conclusion

We developed a sustainable, easy and rapid method of cocrystallization using liquefied fatty acid. As a result, the cocrystallization of TPL : NA, TPL : uera, CAF : MA and IBU : INA was successfully promoted using LA as liquefied fatty acid The addition of liquid during stirring promotes the mass transfer of API and coformer, leading to accelerated cocrystallization. Additionally, the cocrystallization of ITZ : SUC was not allowed with just the addition of LA while it was accelerated with the combination of LA and high-pressure CO2. The viscosity of fatty acid is reduced under high pressure CO2 by dissolving CO2 into fatty acid, which can promote mass transfer of ITZ and lead to cocrystallization. It may be necessary that the medium has more strong property to promote mass transfer under ITZ cocrystallization than that under TPL cocrystallization because ITZ has larger molecular size than TPL. Conclusively, these results suggest that a cocrystallization with only liquefied fatty acid is an effective approach for a suitable, easy and rapid method and that the combination of liquefied fatty acid and high-pressure CO2 can expand the choices of APIs.

References

[1] Nonappa; Lahtinen, M.; Kolehmainen, E.; Haarala, J.; Shevchenko, A. Cryst. Growth Des. 13, (2013) 346–351.

[2] Friscic, T.; Jones, W. Cryst. Growth Des. 9, (2009) 1621−1673.

[3] Padrela, L.; Rodrigues, M. A.; Tiago, J.; Velaga, S. P.; Matos, H. A.; De Azevedo, E. G. Cryst. Growth Des. 15, (2015) 3175–3181.

[4] Aspenström-Fagerlund, B.; Sundström, B.; Tallkvist, J.; Ilbäck, N. G.; Glynn, A. W. Chem.-Biol. Interact. 2009, 181, 272−278.

[5] Kashulines, P.; Rizvil, S. S. H.; Harriott, P.; Zollweg, J. A. J. Am. Oil Chem. Soc. 68, (1991) 912– 921.

[6] Jie, L.; Sohrab, R. Preparation and Characterization of Theophylline-Nicotinamide Cocrystal. Org. Process Res. Dev. 2009, 13, 1269−1275.