Our April meeting will feature a seminar on flowsheet simulation and various detailed design and operational options presented by Mike Mendez from 2 to 5 pm followed by an evening presentation on computational fluid dynamics systems by Jaydeep Kulkarni. Attendees will learn how to setup process flow sheets to optimize the performance of biological and chemical reactors, crystallizers, dyers, distillation columns, evaporators, heat exchangers, and vessel heating and cooling systems. After dinner, attendees will be enlightened about the latest technology for analysis of flow in reactors, crystallizers, combustion equipment and mixers.

Far reaching advances have been achieved in process engineering software in this decade. Today's applications offer enormous scope almost to the point that few calculations are beyond the scope of today’s commercial software packages. In the seminar Mike will explore state-of-the-art functionalities intrinsic to the AspenONE Process Engineering Suite. The presentation and demonstrations will parallel the life-cycle path of typical chemical manufacturing assets, which will include conceptual design, front end engineering, equipment design, project economics, process control, safety design, reliability, availability, and maintenance. The focus will be on flowsheet simulation, heat exchanger design, distillation hydraulic analysis and solids process modeling. The program will consist of two segments of approximately ninety-minutes beginning at 2 pm with one fifteen-minute refreshment break between sessions.

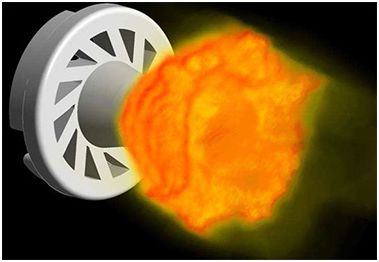

After dinner Jaydeep will demonstrate the application of Computational Fluid Dynamics (CFD) in diverse engineering fields such as chemicals, aerospace & defense, automotive and electronics. Using ANSYS CFD as an example, he will illustrate the depth, ease of use and scalability of today's commercial CFD products. Modern simulation platforms such as ANSYS perform design optimization, multi-physics simulations and even extract reduced ordered models that enable the use of system-level modeling for Digital Twins. CFD is an amazing tool that can accelerate your product design & process optimization.

During this meeting we will recognize our members with over 25 years in AIChE with a memento. We do this for every fifth anniversary after 25 years. As a recipient you will receive a personal invitation. Also, the attendance prize and student awards will be presented.

Attendees will receive 3 PDHs for the seminar and 1 PDH for the dinner talk.

The Speakers

Mike Mendez is a business consultant at Aspen Technology, Inc. (Phone: 281-584-5416; Email: mike.mendez@Aspentech.com) where he has been employed for the past 23 years. Prior to this, he spent the first 14 years of his career designing chemical plants as a process-design engineer with Jacobs Engineering, Fluor Engineers and Monsanto Enviro-chem. He earned BS degrees in Chemistry from Florida Atlantic University and in Chemical Engineering from University of South Florida. Mike is a professional engineer registered in the State of Texas.

Aspen Technology, Inc. is the world’s leading supplier of software that optimizes process manufacturing. Their software tackles the most complex process manufacturing challenges, creating value and improving profitability for customers. With integrated AspenONE software, process manufacturers can optimize their engineering, manufacturing, and supply chains. Customers are better able to achieve operational excellence - increasing capacity, improving margins, reducing costs, becoming more energy efficient, ensuring safety, and shrinking their carbon footprint.

Jaydeep Kulkarni graduated from University of Delaware with a Ph.D. in Chemical Engineering. He currently works at ANSYS, Inc. as a regional technical manager. He is an accomplished engineering leader with passion for technology innovation, business development and mutual value creation with customers. He has a proven track record of speeding up product and process design at large engineering organizations in diverse fields such as chemicals, consumer products, pharmaceuticals, biomedical and nuclear. An example is the isosurface of CO from a burner.

ANSYS is a global leader in engineering simulation. We bring clarity and insight to our customer's most complex design challenges through the broadest portfolio of fast, accurate and reliable simulation tools. Our technology enables organizations in all industries to imagine high-quality, innovative and sustainable product designs that have an accelerated time to market. Founded in 1970, ANSYS employs almost 3000 professionals, more than 700 of them with PhDs in engineering fields such as finite element analysis, computational fluid dynamics, electronics and electromagnetics, embedded software, system simulation and design optimization. Visit www.ansys.com for more information.

|

|

AIChE section members

|

Non-section members

|

Student

|

|

Seminar and Dinner

|

$40

|

$50

|

$15

|

|

Seminar Only

|

$30

|

$40

|

$10

|

|

Dinner Only

|

$20

|

$25

|

$10

|

- Log in to post comments