(79c) Experimental Study of Flow Regimes and Mixing of Dissimilar Fluids in T-Jets Mixers

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

North American Mixing Forum

Novel and Unconventional Mixers

Monday, November 16, 2020 - 8:15am to 8:30am

In the last decades, T-Jets have been applied in different industries, for example, for the production of nanoparticles and in many fast reaction processes. T-Jet mixers consist of two opposite inlets connected to a mixing chamber making up an angle of 90º. Two liquid streams are injected as two high speed jets in the mixing chamber, where they are contacted. T-Jets are usually in the micromixer scale range with widths at jets inlet of approximately the same size as or half of the mixing chamber width.

Sultan et al. (2012) showed, for similar fluids, that the mixing and the flow dynamics depend on the working conditions. Sultan et al. (2012) reported from Planar Laser Induced Florescence (PLIF) experiments and Computational Fluid Dynamic (CFD) simulations that geometric parameters also affect the mixing and the flow dynamics. Therefore, the flow regimes in T-Jet mixers are affected by the momentum ratio of jets, the chamber-to-injector width or chamber-to-depth ratios and jet’s Reynolds number, which is given by Re=Ïvinjw/μ where Ï is the density of the inlet liquid streams, vinj is the inlet streams superficial velocity, w is the width of injector and μ is the viscosity of fluid.

Four distinct flow regimes have been identified in T-Jets mixers: segregated flow regime, vortex flow regime, engulfment flow regime and chaotic flow regime. In segregated flow regime, fluids flow from the inlet to the outlet without being mixed, and so each fluid remains in each side of the mixing chamber (Bothe et al., 2008; Soleymani et al., 2008; Sultan et al., 2012). In vortex flow regime, two Dean vortices are formed in each side of the mixing chamber (Bothe et al., 2008; Soleymani et al., 2008; Sultan et al., 2012; Mariotti et al., 2018). In engulfment flow regime, the two liquid streams are rotated over the mixing chamber creating a single vortex that engulfs both streams (Bothe et al., 2008; Soleymani et al., 2008; Sultan et al., 2012; Zhang et al., 2018). In chaotic flow regime, the flow is characterized by the formation of a vortex street, which promotes the fast mixing of two fluids from the impingement point to the outlet (Sultan et al., 2012).

Sultan et al. (2012); (2013) defined the transition of flow regimes as the onset of the chaotic flow regime, which is characterized by the formation of mixing structures. The critical working conditions for the onset of chaotic flow regime is a function of Re and T-Jets geometry. The more effective mixing conditions were reported for a ratio of chamber-to-injector width of 6, a ratio of chamber-to-depth above 2 and Re above 300.

The transition of flow regimes and the onset of chaotic flow regime were only identified at symmetric flow conditions, i.e., when both inlet liquid streams fluids have equal viscosity, density and flow rates. However, in most of T-jets applications, such as, in the production of polymers, the two liquid streams have different viscosities and densities. This work addresses the mixing of dissimilar fluids in T-Jets mixers using PLIF experimental data.

Experimental Set-Up

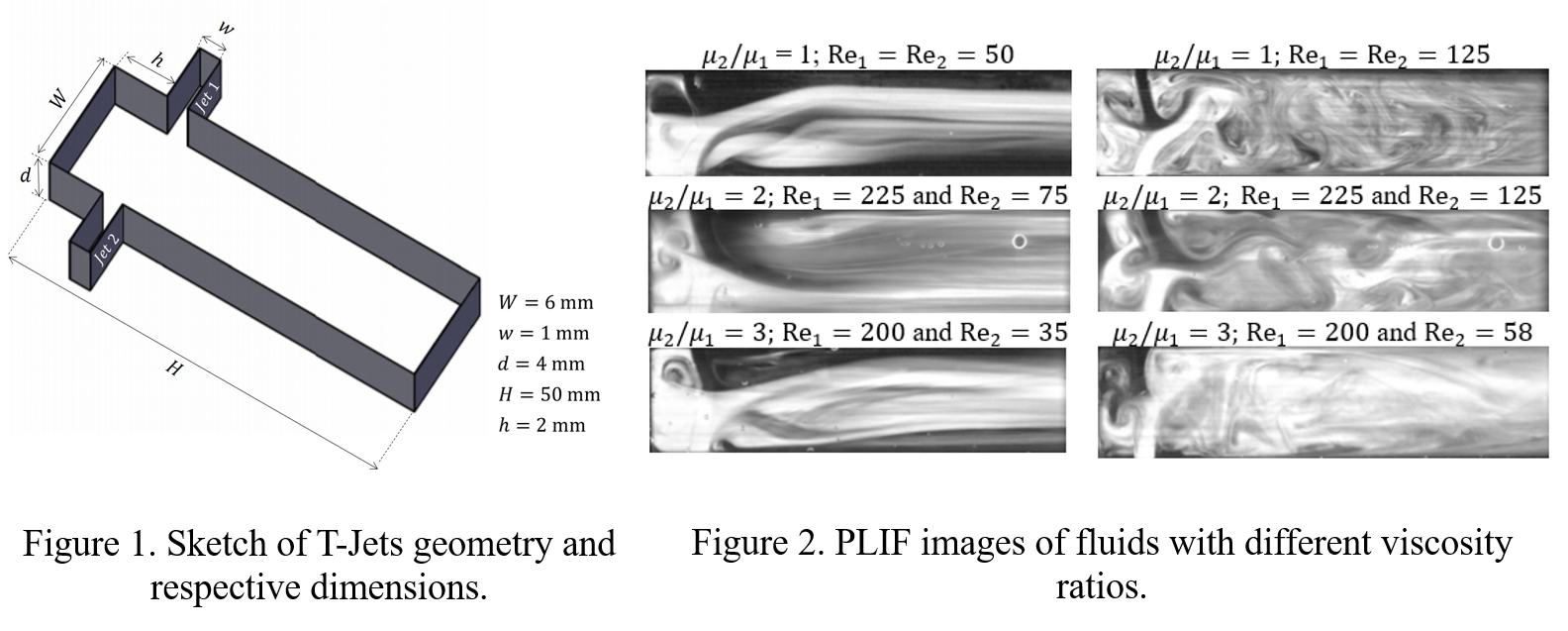

Figure 1 shows a schematic drawing of T-Jets geometry and the respective dimensions. The mixing of two dissimilar fluids was experimentally studied in a range of Re from 100 to 500.

Three distinct viscosity ratios were studied: μ2/μ1=1, μ2/μ1=2 and μ2/μ1=3, where μ1 and μ2 are the viscosities of liquid streams injected from jet 1 and jet 2. The working fluids were aqueous solutions of glycerol and water. For μ2/μ1=1, clear water was injected in one of the injectors and an aqueous solution of rhodamine 6G from the other injector. For μ2/μ1=2 and μ2/μ1=3, an aqueous solution of glycerol dyed with rhodamine was injected in one of the injectors and water was injected from the other one. The refraction indexes of solutions of glycerol and water were matched using calcium chloride dehydrated. For viscosity ratios 1:2 and 1:3, the viscosities of the aqueous solution of glycerol were μ2=2 mPa.s and μ2=3.6 mPa.s.

Results and Discussion

Figure 2 shows PLIF images of mixing of two liquids with a viscosity ratio of 1:1, 1:2 and 1:3 at different Re at the inlets. In Figure 2, the white jet corresponds to the aqueous solutions of glycerol dyed with rhodamine, which was injected from injector 2. The black jet was injected from injector 1 and corresponds to the aqueous solution of calcium chloride dehydrated for the viscosity ratios of 1:2 and 1:3, and clear water for viscosity ratio of 1:1.

For a viscosity ratio 1:1, two different flow conditions were visualized, at Re1=Re2=50 and Re1=Re2=125. At Re=50, no mixing structures at the plane of the mixing chamber axis are visualized whereas the two liquid streams are transported from one side of the mixing chamber to the other. This means that two Dean vortices were formed in the mixing chamber and so the regime is called vortex flow regime. At Re=125, a vortex street is formed in the mixing chamber, which engulfs the two liquid streams promoting its mixing. Therefore, the onset of the chaotic flow regime occurs at 50<Re<125.

PLIF images also show the mixing of fluids with a viscosity ratio 1:2 at Re1=225 ∧ Re2=75 and Re1=225 ∧ Re2=125. At Re2=75, two Dean vortices are formed in each side of the mixing chamber, promoting the mixing of the two phases. At Re2=125, the two liquid streams are engulfed by mixing structures and so the regime is called by chaotic flow regime. These PLIF images show that the transition for the self-sustainable chaotic flow regimes occurs at Re1=225 and 75<Re2<125.

PLIF images show the flow regimes at Re1=200 ∧ Re2=35 and Re1=200 ∧ Re2=58 for a viscosity ratio 1:3. At Re1=200 ∧ Re2=35, figures show that the flow regime is the vortex flow regime. And at Re1=200 ∧ Re2=58, mixing structures are typically formed at chaotic flow regime. So, the onset of the chaotic mixing occurs at Re1=200 and 35<Re2<58.

Figure 2 demonstrates that T-jets can be used to mix dissimilar liquid streams under an intense chaotic flow dynamics, even for a viscosity ratio of 1:3. Figure 2 also identifies the onset of the dynamic flow, which only occurs when the contact of the two liquid streams coincides to the mixing chamber axis. This means that the two jets must be balanced. Therefore, the critical conditions for the effective mixing are the balancing of jets and the onset of the self-sustainable chaotic flow regime.

Conclusions

This work clearly shows that T-Jets mixers are able to mix liquids with viscosity ratios from 1:1 to 1:3 under chaotic flow regimes that promotes fast effective mixing of both liquids. The necessary condition for the effective mixing of fluids is clearly demonstrated in this work: the balancing of jets.

References

Bothe, D., Stemich, C., Warnecke, H.-J., 2008. Computation of scales and quality of mixing in a T-shaped microreactor. Computers & Chemical Engineering 32, 108-114.

Mariotti, A., Galletti, C., Mauri, R., Salvetti, M., 2018. Steady and unsteady regimes in a T-shaped micro-mixer: Synergic experimental and numerical investigation. The Chemical Engineering Journal 341.

Soleymani, A., Kolehmainen, E., Turunen, I., 2008. Numerical and experimental investigations of liquid mixing in T-type micromixers. Chemical Engineering Journal 135, S219-S228.

Sultan, M.A., Fonte, C.P., Dias, M.M., Lopes, J.C.B., Santos, R.J., 2012. Experimental study of flow regime and mixing in T-jets mixers. Chemical Engineering Science 73, 388-399.

Sultan, M.A., Krupa, K., Fonte, C.P., Nunes, M.I., Dias, M.M., Lopes, J.C.B., Santos, R.J., 2013. High-Throughput T-Jets Mixers: An Innovative Scale-Up Concept. Chemical Engineering & Technology 36, 323-331.

Zhang, J., Liu, S.-f., Cheng, C., Li, W.-f., Xu, X.-l., Liu, H.-F., Wang, F.-c., 2018. Investigation of three-dimensional flow regime and mixing characteristic in T-jet reactor. Chemical Engineering Journal 358.