(547d) A Cellulosic Shell Installed Onto Nanoparticles Protects Cores from Organic Solvents

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Particle Technology Forum

Nanoparticle Coatings and Nanocoatings on Particles

Friday, November 20, 2020 - 8:45am to 9:00am

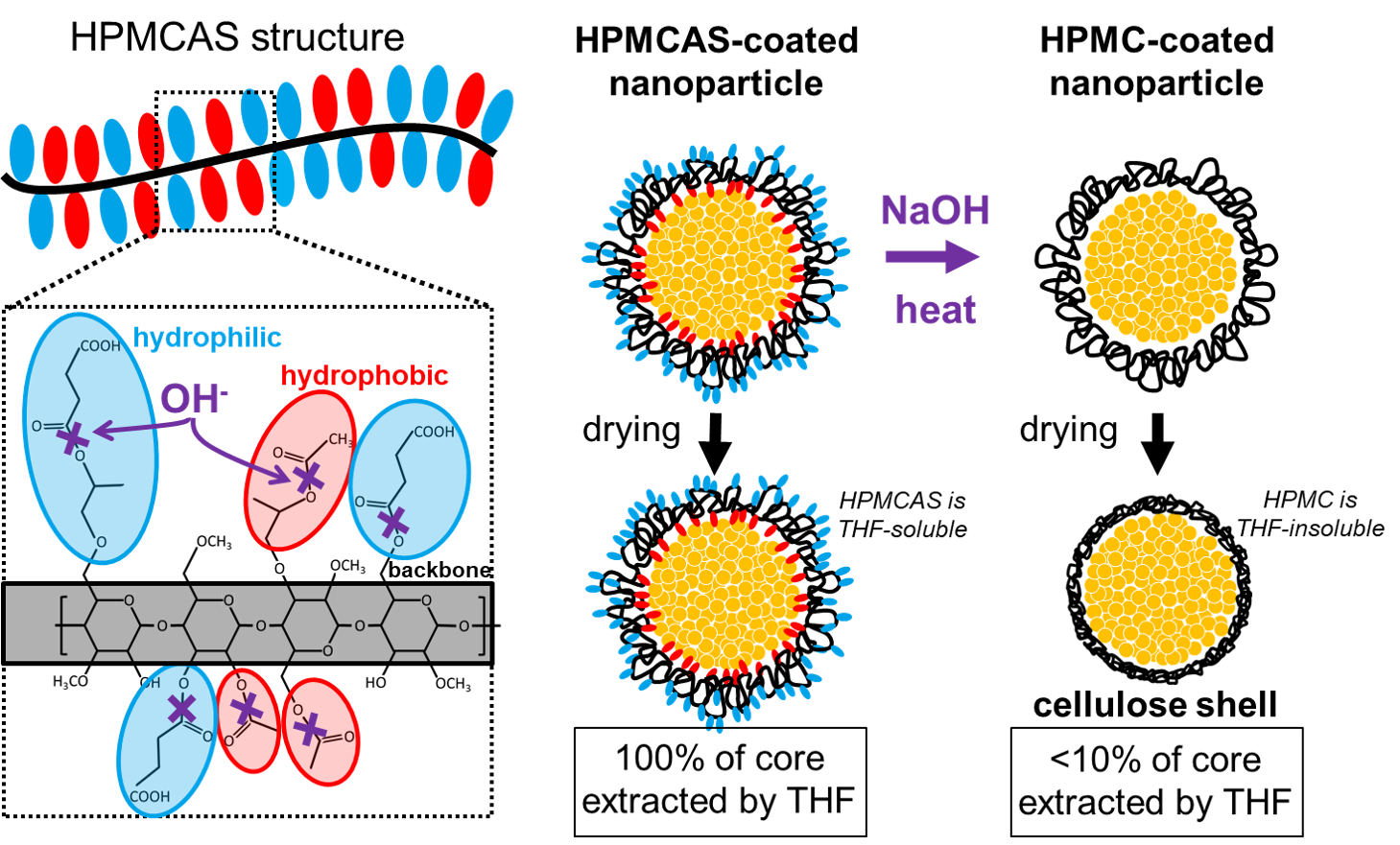

We here describe the discovery and characterization of a cellulosic layer on nanoparticle surfaces that protects particle cores from organic solvents. Core-shell nanoparticles 150nm in diameter are formulated using Flash NanoPrecipitation (FNP) and contain a core made of lumefantrine, a model hydrophobic antimalarial drug, and a shell made of hydroxypropyl methylcellulose acetate succinate (HPMCAS), an amphiphilic polymer commonly used as a pharmaceutical excipient. Following FNP, NaOH is added to the nanoparticle suspension, which is then spray dried. During drying, the caustic environment de-esterifies the HPMCAS layer coating the nanoparticles, removing the acetyl and succinyl substitutions from the backbone. The de-esterified HPMCAS – now hydroxypropyl methylcellulose (HPMC) – then vitrifies to form a glassy layer around the NP cores. The HPMC shell layer is impermeable to many organic solvents, and with it in place, less than 10% of the lumefantrine core can be extracted using THF (in which it is readily soluble). Without the NaOH treatment, the THF-soluble HPMCAS shell is dissolved and 100% of the lumefantrine is extracted.

The HPMC shell is characterized by NMR and DSC to confirm its chemical and thermal properties. Necessary conditions for the NaOH treatment and drying are identified, and a method for washing the spray dried powders to remove excess dry NaOH is described. The layer’s ability to protect the core is then tested against a variety of common organic solvents. We then describe possible uses for this technique in catalyst and personal care applications, such as temperature-triggered catalyst release or crush-induced fragrance delivery.