(513ds) Pressure Drop and Conversion in Catalytic Particulate Filters Depending on the Washcoat Distribution

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Catalysis and Reaction Engineering Division

Poster Session: Catalysis and Reaction Engineering (CRE) Division

Friday, November 20, 2020 - 8:00am to 9:00am

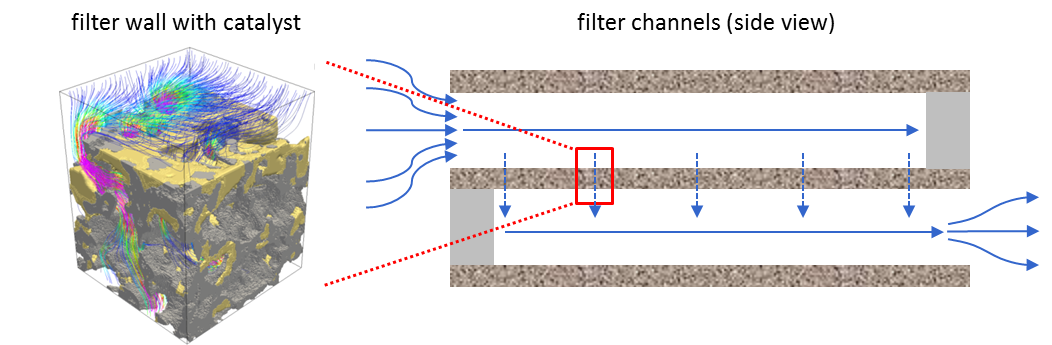

Low pressure drop and sufficient catalytic activity are key parameters of a catalytic particulate filter for automotive exhaust gas aftertreatment. These parameters strongly depend on the distribution of catalytic coating on and inside the porous filter wall. This contribution summarizes experimental tests of several catalytic filter samples with different coating structures. Model catalytic particulate filters were obtained by lab washcoating of the milled Pt/γ-Al2O3 catalyst slurry onto the cordierite filter cores with the diameter 2.5 cm (drilled from the full-size filter brick provided by Corning). Several different particle size distribution of the catalyst microparticles in the slurry were used, leading to different properties and location of the catalytic washcoat in the filter. The sample pressure drop was first measured at several different flow rates of nitrogen at room temperature. The catalytic activity was then tested in a heated tube reactor with the inlet mixture of synthetic gases (CO, O2, H2, C3H6, NO, CO2, H2O and N2) simulating the real exhaust gas. The outlet gas composition was analyzed by FT-IR MKS HS 2030 and MS Hiden QGA. The obtained results suggest that the initial light-off temperature is not affected much by different catalyst distributions. However, noticeable differences exist in reactant slip at higher temperatures and flow rates due to different extent of mass transfer limitations. Pressure drop is the most sensitive property depending on the coating distribution in a particulate filter.

Acknowledgements

This work was financially supported by the Czech Science Foundation (GA 19-22173S) and specific university research (MSMT No 21-SVV/2020).

References

- KoÄà P., Isoz M., Plachá M., Arvajová A., VáclavÃk M., Svoboda M., Price E., Novák V., Thompsett D. 3D reconstruction and pore-scale modeling of coated catalytic filters for automotive exhaust gas aftertreatment. Catalysis Today 2019, 320, 165-174.