(164e) Mixed Solvents for Rapid Photo-Thermal Patterning of Conjugated Polymers

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Materials Engineering and Sciences Division

Poster Session: Materials Engineering & Sciences (08E - Electronic and Photonic Materials)

Thursday, November 19, 2020 - 8:00am to 9:00am

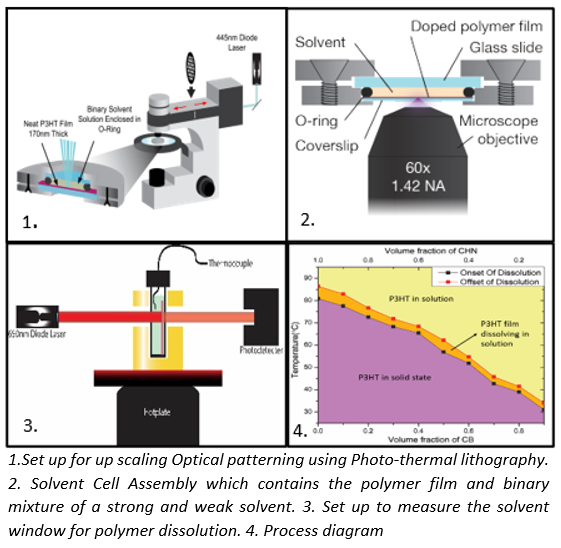

OPVs (Organic Photovoltaics) have received widespread attention due to their promising qualities like solution processability, low temperature manufacture, tunable electronic properties and cheap and lightweight materials. A significant obstacle for the industrial development of OPVs is the lack of a patterning technology that is inexpensive, rapid and viable. Patterning helps create deep light trapping structures which help improve light capture in sub-band gap states. The aim of this project is to optically write lateral light trapping structures into Bulk Heterojunction layers by upscaling optical patterning using photo-thermal lithography. The light trapping structures will increase the external quantum efficiency of the sub-gap Charge Transfer-state absorbance across a broad wavelength range. Photo-thermal lithography (Set up shown in Fig 1) uses light to locally heat a conjugated film, which causes the heated polymer to dissolve into a solvent layer (Assembly of solvent cell shown in Fig 2). The critical design parameters are to maximize the pattern resolution and write-speed, which are both governed by the solvent quality. This presentation demonstrates a reproducible method to measure the solvent processing window for photo-thermal lithography using mixed strong and weak solvents such that polymer will not dissolve at room temperature, but will dissolve completely when laser heated to a specified dissolution temperature as depicted in the process diagram(Fig 4). We then demonstrate photo-thermal patterning of P3HT wires with < 1 µm diameter as a function of solvent quality and laser dose to demonstrate the functional relationship. Using these process parameters, we can achieve rapid sub-micro patterning, demonstrating viable patterning of OPV materials.