The efforts for energy conservation are requested because of the limitation of fossil fuel and the environmental issue of global warming. The petrochemical and steel industries are especially the largest energy-consuming manufacturing industries. While large amount of waste water with the range of 60-90°C is released from these industrial processes, steam is demanded and generally provided from large quantities of fossil fuel. The system to generate high-temperature steam from waste heat is therefore required for the effective utilization of energy. In this study, a novel steam generation system using a direct heat exchange system with adsorbent-water pair is proposed. Contact between water and adsorbent results in evaporation of excess water due to the release of adsorption heat from adsorbent. Because this system does not require any heat exchangers, not only higher packing density of adsorbent particles in the reactor but also lower heat capacity of the reactor is expected. In our previous study, generation of steam under cyclic operation of steam generation and regeneration processes have been experimentally confirmed using zeolite as adsorbent. Superheated steam at 0.1-0.4MPa was generated using water at 80°C and dry gas at 130°C with lab-scale apparatus [1].

The purpose of this study is to investigate performance of the system using water-zeolite pair. For discussing performance of the system, the mass of the steam generated in the cyclic steam generation and regeneration processes is particularly studied. According to the previous study, the system satisfied with the energy balance in the steam generation process [1]. This implies that mass of steam generated can be estimated based on the energy balance between the initial and final states of the steam generation process. While the final state of the steam generation process is independent from the regeneration process, the initial state of the steam generation process strongly depends on the local temperature distributions and distributions of water content in the zeolite after the regeneration process. Therefore estimation of regeneration process is carried out first. Performance of the system is then discussed based on the estimation of regeneration process.

A mathematical model considering transport phenomena during regeneration process is developed. As the governing equations, conservation equations of mass and energy for gas and solid are considered. Ergun's equation is used instead of the momentum conservation equation for gas. The rate of desorption in the model is determined based on the measurement data from thermal analysis. The rate of drying of zeolite is assumed as constant-rate of drying. For the validation of the model, numerical results are compared to experimental one using the laboratory-scale apparatus. As a result, numerical results reasonably agree with the experimental ones with various gas flow rate and temperatures.

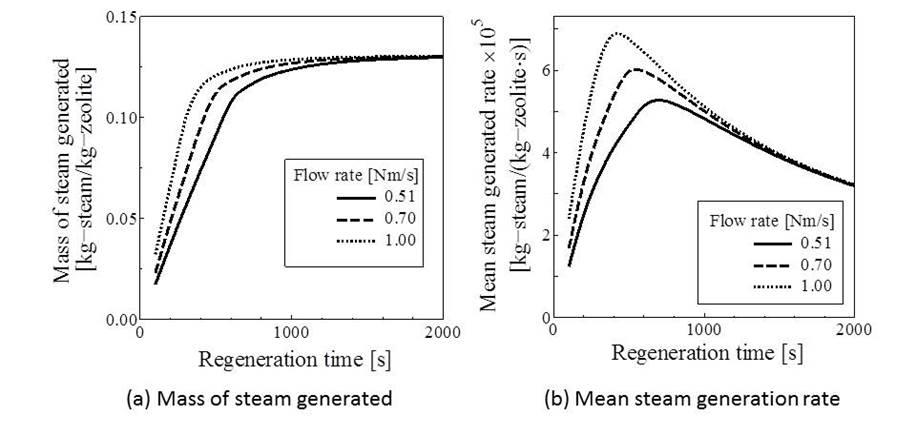

Performance of the system is then discussed in terms of mass of steam generated in the cyclic operation under various regeneration conditions. Because the regeneration process is considered as the energy storage process in the system, mass of steam generated increases with the regeneration time and reaches the saturated value. The typical result is shown in Fig1(a). When the flow rate is 0.51 Nm/s, the mass of steam generated at 140°C (0.36MPa) increases with the regeneration time and reaches the saturated value of 0.13 kg-steam/kg-zeolite. From this result, appropriate regeneration time seems 600-1000 s. To discuss more clearly, the mean steam generation rate is introduced, which is defined as the mass of steam generated during the cycle operation per operation time. For this case, the mean steam generation rate exhibits the maximum value of 0.53x10-4 kg-steam/(kg-zeolite·s) at the regeneration time of 690 s (see Fig1(b)). Accordingly, the maximum mean steam generation rate is used for the following discussion.

Fig.1 Effect of regeneration time on the mass of steam generated at 140°C in cyclic operation (Inlet gas temperature of 200 °C and Dew point of 60 °C for regeneration)

Effect of the regeneration condition on the maximum mean steam generation rate is studied. The regeneration condition such as temperature and dew point of the gas are studied. The typical result is shown in Fig2. The maximum mean steam generation rates tend to decrease when dew point of inlet gas increases above -20°C. When gas temperature is 200°C, the effect of dew point on the maximum mean steam generation rate is not so significant. When the gas temperature is 140°C, dew point of gas should become low to generate steam at 140°C. Consequently, it was found that not only dry gas but also humid gas can be applied to generate steam when gas temperature is enough high. It would be helpful in terms of effective utilization of waste heat such as exhaust gas.

Fig.2 Effect of dew point of the inlet gas for the regeneration process on the maximum mean steam generation rate (Steam temperature: 140°C)

Acknowledgements

This work was partially supported by the NEDO project under Research and Development Program for Innovative Energy Efficiency Technology, and also by the Japan Society for the Promotion of Science (JSPS) Grant-in-Aids for Scientific Research (C) 25420923.

Reference

[1] B. Xue, Y. Iwama, Y. Tanaka, K. Nakashima, A. T. Wijayanta, K. Nakaso, J. Fukai, "Cyclic steam generation from a novel zeolite–water adsorption heat pump using low-grade waste heat", Experimental Thermal and Fluid Science, Vol. 46, 54–63 (2013)