ABSTRACT

Goal of the Project

The primary goal of the project is the creation of composite fuels for combustion processes containing biomass, coal, coal residues, crude oil processing residues, and other combustible material for effective firing in power plants. The project attempts to provide screening equations for the effective combustion of composite fuels and develop the combustion characteristics for effective burning.

Mixtures

The literature is full of data for composite fuels but most include experimental values and not composite equations. We have started with wood-oil composite fuels and will examine other potential fuels.

Experiments

Settling experiments were performed at two different temperatures about 24C and about 66C to understand the effect of temperature on obtaining relatively homogeneous mixtures.

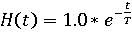

The normalized settling curves follow the equation

Where T is the time constant for exponential settling and the time where the solids have dropped to 37% of the original height. The settling data provided in Tables 1 and 2. The T is the time constant for settling.

Anthracite coal-oil mixtures and pine wood-oil mixtures have been studied. The oil used was soybean oil. The density of these components at 25C is; anthracite coal 1.3 gm/cm3, white pine wood 0.48 gm/cm3, and soybean oil 0.92 gm/cm3.

Table 1. Experimental Parameters and Mass Fractions for Coal/Oil/Water Experiments and Time Constants for Exponential Settling

|

Coal Particle Size Range (mm) |

Mass % Coal |

Mass % Oil |

Mass % Water |

T (at Room temp), min |

T (at elevated temp), min |

|

0.5-1.0 |

0.319 |

0.681 |

0.000 |

2.717 |

2.717 |

|

0.5-1.0 |

0.255 |

0.543 |

0.203 |

9.091 |

12.658 |

|

0.297-0.5 |

0.329 |

0.671 |

0.000 |

2.717 |

2.717 |

|

0.297-0.5 |

0.263 |

0.537 |

0.201 |

3.876 |

5.848 |

|

0.178-0.25 |

0.318 |

0.682 |

0.000 |

1.730 |

3.165 |

|

0.178-0.25 |

0.252 |

0.542 |

0.206 |

7.874 |

14.925 |

|

0.075-0.125 |

0.313 |

0.687 |

0.000 |

55.556 |

40.000 |

|

0.075-0.125 |

0.253 |

0.553 |

0.194 |

142.857 |

111.111 |

Table 2. Experimental Parameters and Mass Fractions for Wood/Oil/Water Experiments and Time Constants for Exponential Settling

|

Average Wood Particle Diameter (mm) |

Mass % Wood |

Mass % Oil |

Mass % Water |

T (at Room temp), min |

T (at elevated temp), min |

|

0.001 |

0.098 |

0.902 |

0.000 |

8.696 |

6.536 |

|

0.001 |

0.048 |

0.736 |

0.217 |

7.407 |

7.407 |

|

0.00001 |

0.061 |

0.939 |

0.000 |

18.182 |

10.526 |

|

0.00001 |

0.077 |

0.708 |

0.215 |

111.111 |

13.889 |

The emulsions with approximately 20 % water in the mixture and markedly slowed down the settling time and kept the wood in suspension.

Modeling Equations

Viscosity, density, heating value, time for vaporization, exchange coefficient, temperature of combustion, sulfur content, burning rate constant, thermal diffusivity and flame temperature, and other parameters can be modeled for all these composite fuels.

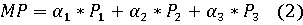

The linear format of a three component mixture that can be used to calculate some properties is given by

where α is a weighting coefficient and P is the single component property of interest.

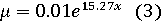

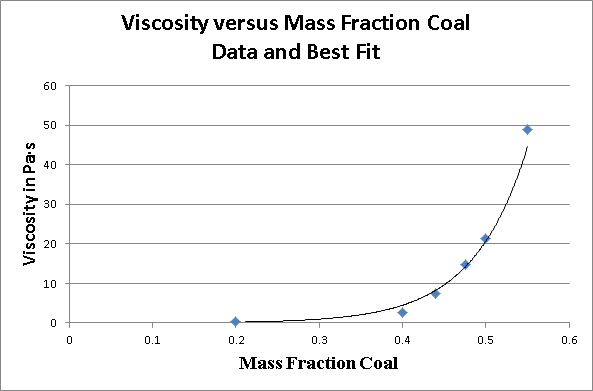

Figure 1 presents the viscosity of coal-oil mixtures (Timbalia). It has an exponential increasing form. An interesting thing to note is that the viscosity of small amounts of coal is less than the liquid oil viscosity of 0.65 Pa-s. The curve in Figure 1 can be fit to a relatively high accuracy with the equation

This can be used as a model to calculate wood-oil properties.

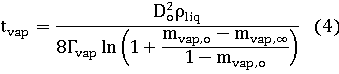

Nonlinear equations of the form for the time of evaporation can be used as weighting factors for the appropriate model equation (Spaulding).

Figure 1 Viscosity of number 8 coal and number 6 oil-mixtures at 25C. (Ref Timbalia)

Forming Emulsions

Emulsions of these mixtures will be dependent upon the energy used to create the emulsions. Hydrocavitators have been shown to be able to add the energy required to form relatively stable emulsions (Knickle). Special design of burner nozzles can be produced to take and effectively use these emulsions.

Future Work

Work is continuing on the development of the modeling equation and their justification.

References

Knickle, H. et al ?Innovative Hydrocavitation Technology Process to Create Composite Fuels? AIChE Spring Meeting, Session 141, Houston TX (2012)

Spaulding, D. B. ?Combustion and Mass Transfer?, (1979) Introduction to

A. Timbalia, Master's Thesis-Ohio University June 1981

Presenter(s)

Language

Pricing

Individuals

| AIChE Member Credits | 0.5 |

| AIChE Pro Members | $15.00 |

| Fuels and Petrochemicals Division Members | Free |

| AIChE Graduate Student Members | Free |

| AIChE Undergraduate Student Members | Free |

| AIChE Explorer Members | $25.00 |

| Non-Members | $25.00 |