(546f) Effect of Geometry and Interfacial Energy to Permeation of Liquid through Filter Pores

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Engineering Sciences and Fundamentals

Fundamentals of Interfacial Phenomena

Sunday, November 5, 2023 - 5:00pm to 5:18pm

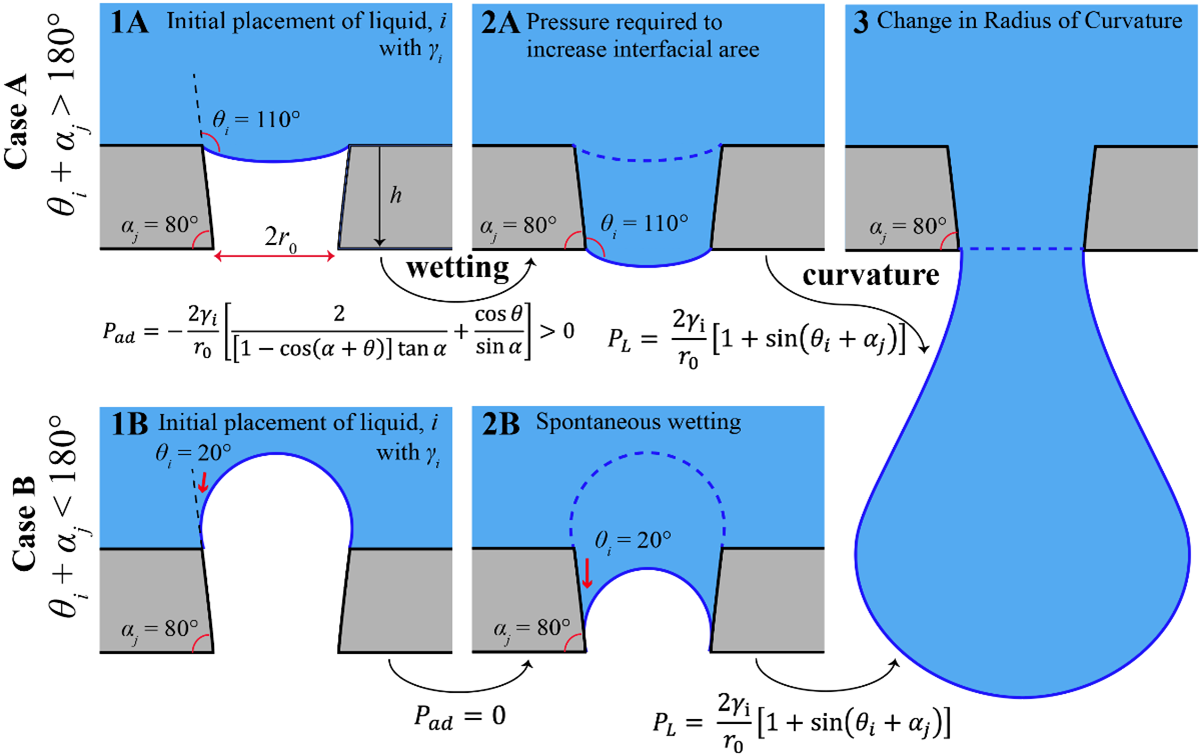

To do so, an equation was developed that enables the calculation of the pressure for a liquid species, i, to permeate through a pore with the wall angle at αj. By accounting for three kinds of resistance, that is, (1) the adhesion energy from increasing the liquid-solid interface, (2) the Laplace pressure that is needed to flatten the liquid-vapor interface, and (3) the cohesion at the neck of a liquid droplet before it is detached from the bottom of the pores, the pressure for a liquid species, i, to permeate through a pore with its pore wall angle αj can be calculated as below with γi being the surface tension of the liquid and r0 being the radius at the bottom of the pore. (Please refer to the geometry and the equation in the attached image.)

The height to permeate, hi,j, can be simply calculated by hi,j = Pi,j/Ïg with Ï being the liquid density and g being the gravitational acceleration. This equation was verified experimentally by preparing a cylindrical or tapered pore using a 3D printer, after which it was coated with PDMS to decrease the roughness and the easiness of surface modification.

The contact angle of PDMS was altered by exposing the pore to UV-ozone. A glass tube was placed upon the pore and water was added gradually to observe the height at which the liquid started to permeate. The results that related the height to permeate as a function of θi were found to have the same functional form as the equation developed, clearly showing that the decrease in θi decreased the height to permeate and increased permeability. The discrepancy between the equation and the observation was investigated by confirming the shape and the location of the meniscus inside the pore with 3D confocal microscopy. The result showed that the deviation was due to the uncertainty in geometry caused by the low resolution of the 3D printer (25 μm in the xy plane) used for fabrication. This made the shape of the meniscus different from the shape that could be predicted by the theory that assumes a perfectly smooth pore wall. To investigate the effect of αj, tapered holes with various αj were printed, and coated with PDMS but used without further altering the contact angle. It is observed that the increase in the pore wall angle decreased the height to permeate. Since this was contrary to the developed theory, the shape and the location of the meniscus were again investigated with 3D confocal microscopy to understand the discrepancy. It also showed that the uncertainty in geometry caused the deviation. Though the discrepancies for both θi and αj were observed due to the unexpected geometry, the theory could predict the behavior when such geometry was accounted for. This would provide the way to utilization of filters in an industrial setting where the perfect smoothness cannot be achieved.