(536i) Feasibility Assessment of Recycling Abandoned Aluminum Dross As Catalyst for Biomass Pyrolysis to Produce Hydrogen-Rich Gas

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Forest and Plant Bioproducts Division

Catalytic and Thermochemical Conversion of Lignocellulosic Materials II

Wednesday, November 8, 2023 - 2:38pm to 2:54pm

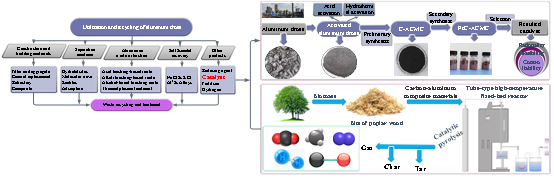

Methods. This study begins with the problems such as low activity, high cost, poor anti-coking properties, easy coking and poisoning, and short lifespan of existing catalysts for catalyzing the conversion of biomass into high-quality hydrogen-rich gas, followed by briefly introducing the characteristics, hazards, types, composition, and sources of aluminum dross. Next, with aluminum dross as a base material, we propose to preliminary synthesize carbon-aluminum composite materials by loading active components-carbon sources onto activated aluminum dross with a hydrothermal method. The hydrothermal method is utilized to load transition metal of iron onto the surface and pores of the selected carbon-aluminum composite material to prepare a carbon-aluminum composite material-supported iron catalyst. The pore structure, surface characteristics, and thermal stability of the catalyst are all characterized. Finally, using poplar sawdust as the raw material, the thermal decomposition product yield, gas release rate and yield are investigated as the main indicators to explore the impact of the catalyst on the thermal decomposition of biomass, and to comprehensively evaluate the feasibility of using aluminum dross to catalyze the conversion of biomass into hydrogen-rich gas.

Results and Discussion. The results indicate that the stability of activated aluminum dross is significantly improved, obtaining a larger specific surface area and pore volume. In particular, the acetic acid-activated aluminum dross has a specific surface area of 178.4 m2/g, an average pore size of 9.40 nm, a pore volume of 0.42 cm3/g, and a thermal conductivity coefficient of 0.3151 W/mK, which has similar pore structure characteristics to alumina oxide. In the carbon-aluminum composite material, the carbon sources are combined with the metallic oxides in the aluminum dross to form C-O-M clusters through hydrogen bonds or van der Waals forces, with a specific surface area, average pore size, and pore volume of 118 m2/g, 10.3 nm, and 0.43 cm3/g, respectively. It has a well-developed pore structure and a thermal conductivity coefficient of 0.2194 W/mK, and exhibits the advantages of both activated carbon and alumina oxide as a catalyst for catalytic biomass pyrolysis and gas reforming reaction, thus can be used as an excellent catalyst carrier for catalytic biomass pyrolysis to produce hydrogen-rich gas and gas reforming reaction. The carbon-aluminum composite material further loaded with iron exhibits a strong metal-support synergistic effect on the surface. This enhances the ability of the aluminum dross to promote reforming and cracking reactions, leading to the cleavage of heavy chain volatiles into lighter molecules and gases, resulting in a higher gas yield (43.77%) and lower coke deposition (19.79%). The H2 yield is significantly improved to 64.24 ml/g-biomass, providing a promising route for the pyrolysis of biomass to produce hydrogen-rich gas.

Conclusion. It is feasible to recycle abandoned aluminum dross as catalyst for biomass pyrolysis to produce hydrogen-rich gas. This approach represents the reuse of waste resources and can effectively promote the efficient conversion of biomass and by-products, laying a theoretical foundation for the application of waste resources in the fields of environment, energy, and chemical industry, achieving the dual goals of protecting natural resources and obtaining economic benefits.