(499f) Hierarchical Layered Composite Thin Film Manufacturing Via a New 3D Printing Technique

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Materials Engineering and Sciences Division

Excellence in Graduate Student Research (Area 08A)

Tuesday, November 7, 2023 - 1:45pm to 2:00pm

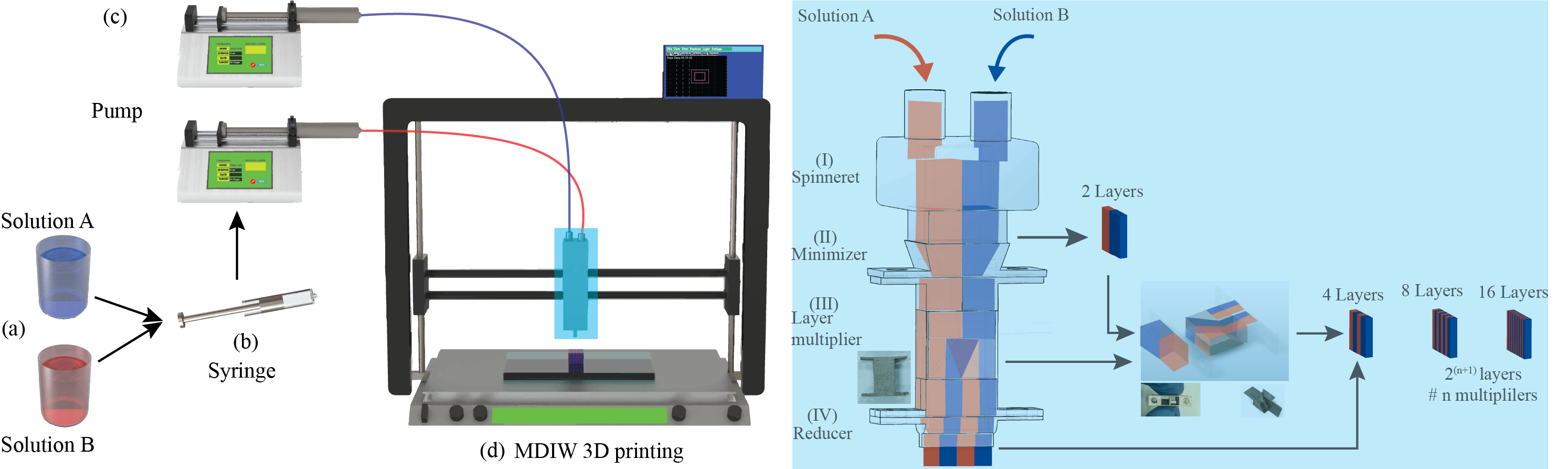

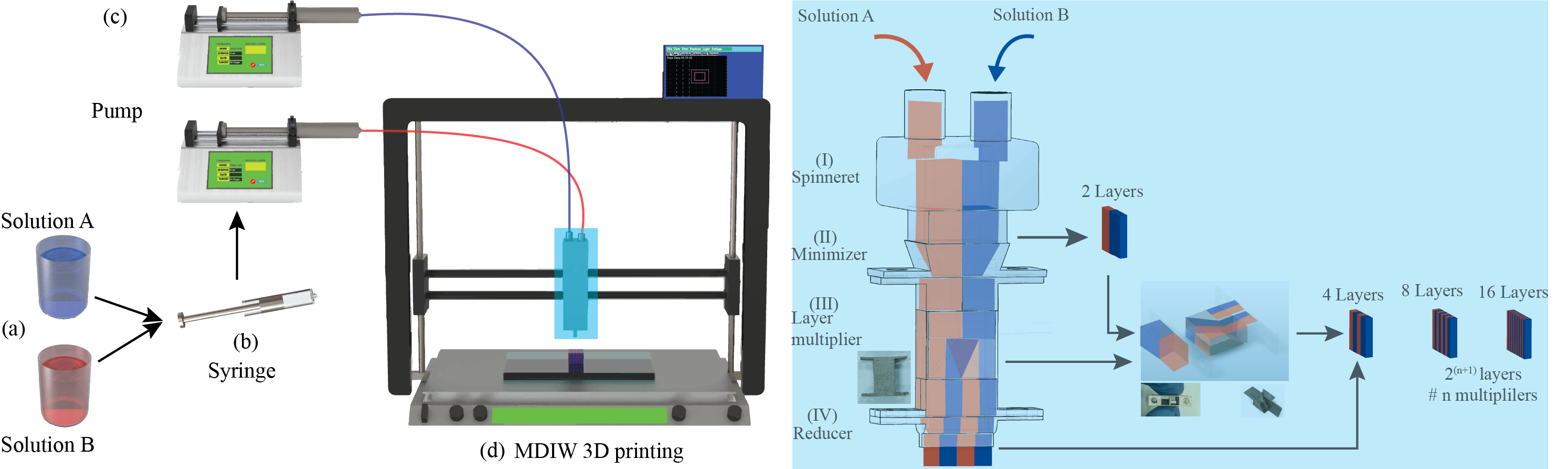

Polymer films have found a variety of applications in electronics, solar panels, antennas, tissue engineering, soft robotics, gas separations, and many more. The advent of 3D printing has made it possible to construct polymer films of different sizes, shapes, and functionality, but limits the achievable properties such as isotropy, material selection, and composition. Here we present a new solution-based 3D printing technique with a uniquely designed nozzle called the multiphase direct ink writing (MDIW) for producing thin films and membranes. The nozzle was designed to replicate the layered patterns found in nature such as in tree barks or the rainbow mountains for improving the composite material properties and functionalities. The MDIW has provision to include two immiscible heterogeneous material compositions such as polymer solutions, nanoparticle dispersions, or polymer blends to produce alternatively layered structures. The alternative layer formation within each printed line is effective in achieving a high polymer chain confinement and the nanoparticle packing factor has shown improvements in the uniaxial mechanical properties. By controlling the solution rheology, flow behavior, and printing strategy thermal and functional properties of the films are also improved. The versatility of the MDIW 3D printing process is demonstrated using a few different polymer and nanoparticle combinations such as PVA, TPU, PCL, CNT, and Fe3O4. The MDIW 3D printing technique has shown promising applications in structural support, thermal dissipation and management, smart materials, and soft robotics.