(440c) Need for Integrating Carbon Mitigation Strategy and Innovation Planning Problems to Achieve Net Zero Emissions

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Computing and Systems Technology Division

Planning, Scheduling, Supply Chain and Logistics I

Sunday, November 5, 2023 - 4:10pm to 4:30pm

Previous works have developed portfolio optimization models to solve the carbon capture planning problem. These works select emission sources and capture material and technology to minimize the overall cost of deployment and operation while meeting capture targets [4-7]. They optimize the supply chain of CO2 capture, utilization, and sequestration. However, they do not consider the possibility that the selected technologies might be in different stages of development, which can delay the capture project deployment and incur a penalty due to unmet capture targets.

Innovation projects are planned by optimally allocating limited resources based on the expected return on investment [8]. In the case of carbon capture, the resource allocation for a technology developed for capture from a specific emission source also depends on the expected deployment time of the source’s capture facility. Thus, technology developed at a faster pace need not necessarily correspond to maximal cost saving relative to another technology developed at a slower pace. The availability of funds and resources limits both capture project planning and technology development. These observations suggest that capture project planning and technology development are closely interrelated problems. Similar arguments can be made for other carbon mitigation strategies.

This work investigates how planning of carbon mitigation strategy development and technological innovation affect each other. The results are utilized to determine the extent of the link between strategy deployment and innovation planning problems. Carbon capture is selected as the mitigation option and development of capture technologies as the innovation planning. We developed three multiperiod mathematical programming models, two corresponding to each planning problem and one to the integrated planning problem. The individual planning problems are sequentially solved iteratively. The capture planning problem is solved first because the development problem requires the capture facility deployment information. The comparison of the iterative and integrated problem solutions helped identify the conditions under which the two problems should be integrated.

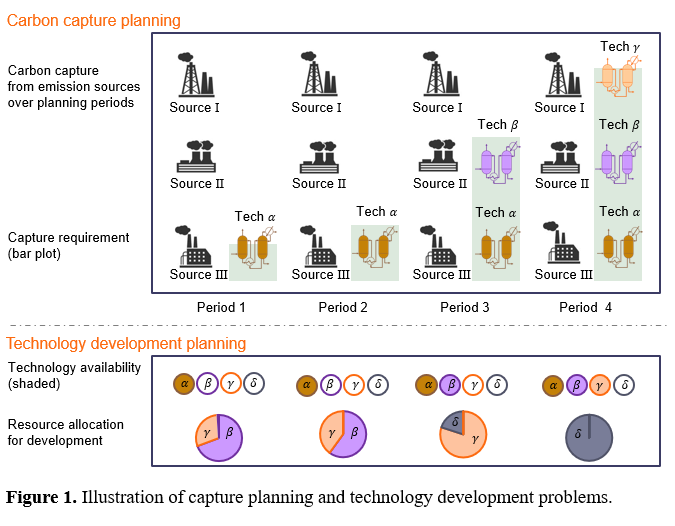

The capture planning problem is modeled as a multiperiod portfolio optimization problem [7] and illustrated in Figure 1. Given capture requirements (bar plot) from a set of emission sources (â… to â…¢ in Figure 1) over planning periods (1 to 4 in Figure 1), the objective is to minimize the capture cost by making several strategic and operational decisions simultaneously, such as 1) the capacity of the capture facility implemented for a source and the time period at which the facility becomes operational, 2) the annual capture extent from the source to meet the capture targets, 3) a commercial, compatible, and cost-effective capture technology for the facility, and 4) capacity expansions needed over time to meet the higher capture targets. The capture facility implementation for different sources is represented with the capture technologies and in Figure 1. The cost models for post-combustion capture technologies are used to estimate the annualized investment cost and annual operating costs of the capture facilities [5]. The multiperiod model is formulated using mixed-integer non-linear programming (MINLP). Due to the high computational cost associated with solving real-world size problems, a solution approach using mixed-integer linear programming (MILP) relaxation is employed to solve the problem [7].

The technology development problem is modeled as a multiperiod resource allocation problem and illustrated in Figure 1. It consists of a set of technologies ( in Figure 1) at different stages of development, such as research and development, pilot testing, demonstration, and commercialization, during the planning period. A shaded symbol (Figure 1) in technology availability represents its commercial availability. Allocation of necessary resources enables a technology to progress to subsequent development stages. For example, in Figure 1, technology is unavailable during period 1, and it is developed with resource allocation to become commercially available for source â…¡ by period 3. The capture facility information from the capture planning problem, including capture facility capacity, time of facility implementation, and its operational extent over time, are given as parameters to the model. With limited resources available over the planning horizon, the objective of the development problem is to minimize the total cost of capture and technology development by optimal allocation of resources to develop new technologies for implementation in the planned capture facilities. This problem is formulated as a MILP model.

A case study for planning capture was constructed by selecting four emission sources from major CO2-emitting industries: power, cement, iron and steel, and refinery [9]. The CO2 reduction targets increase by 10% biannually from 30% to 70% over the planning horizon of 10 years (discretized into ten equal time periods) for the case study. For the technology development problem, two technologies using post-combustion capture techniques are considered- monoethanolamine-based absorption (ABS-MEA) is assumed to be commercially available, and pressure swing adsorption using methyl viologen exchanged zeolite Y (PSA-MVY) is under development. Previous studies have shown that PSA-MVY is more cost-effective than ABS-MEA [5,7]. It is assumed that PSA-MVY takes two years of research and development and two more years of pilot testing for commercial implementation. A 30% contingency cost is added for the pilot plants. The optimization models are formulated in Python V3.8.6 using PYOMO V6.4.1 and solved to an optimality gap of 1% using the solution approach in [7]. The MILP models are solved using CPLEX V20.10, and initialized MINLP models are solved using DICOPT V2 through GAMS V24.8.5. The power plant with the highest CO2 emission rate is selected for capture in the first four periods to meet the annual capture targets. The deployed capture facility uses commercial technology. As the capture requirement increases over the planning horizon, capture facilities are implemented for sources at cement and iron, and steel industries in the fifth and ninth periods, respectively. There is sufficient time and resources for pilot testing PSA-MVY at these sources; hence PSA-MVY is used by their capture facilities. In addition to these facilities, the capture facility at the power plant operates at its maximum capacity to meet the capture target, which leads to a high capture cost as the facility uses ABS-MEA. This condition is overcome by solving an integrated problem, which optimally plans for the technology development and facility deployment to ensure maximum capture from facilities using the cost-effective new technology. The capture facility in the iron and steel industry using PSA-MVY is deployed in the seventh period. An expansion capacity is added to it in the ninth period to capture 90% of the carbon emitted by the source. These decisions reduced the total capture cost by 4.6% in the last four planning periods and overall project cost by 1.4%.

The results reveal that capture facilities for high CO2 emitting sources become operational in the initial periods of the planning horizon in the capture problem. There is insufficient time/resources to develop new technologies for these facilities in the development problem. Hence, the facilities use the available technologies. The solution of the integrated problem optimally plans for the delayed deployment of some CO2 facilities to allow for enough time to develop new technologies for the facility. Such planning decisions reduce the overall cost of the capture project with the use of cost-effective technologies. Thus, to determine an optimal trade-off between capture facility deployment and new technology development decisions, the two planning problems should be solved with an integrated solution approach.

References

- IEA (2022), The Need for Net Zero Demonstration Projects.

- IEA (2022), Carbon Capture, Utilisation and Storage.

- IEA (2022), Large-scale CO2 capture projects in industry and transformation, actual vs. Net Zero Scenario, 2020-2030.

- Han, J. H., Lee, J. U., & Lee, I. B. (2012).

- Hasan, M. F., Boukouvala, F., First, E. L., & Floudas, C. A. (2014).

- Roh, K., Alâ€Hunaidy, A. S., Imran, H., & Lee, J. H. (2019).

- Santhamoorthy, P., Subramani, H. J., and Cremaschi, S. (2023). FOCAPO/CPC.

- Tan, R. R., Aviso, K. B., & Ng, D. K. S. (2019).

- Leeson, D., Mac Dowell, N., Shah, N., Petit, C., & Fennell, P. S. (2017).