(279f) Operational, Economic, and Environmental Comparisons of Solar Energy Integration Methods for a High Temperature Steam Electrolysis Plant

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Topical Conference: Sustainable Pathways Toward Hydrogen and Synthetic Fuels

Sustainable Pathways to Clean Hydrogen and Synthetic Fuels IV

Tuesday, November 7, 2023 - 10:05am to 10:30am

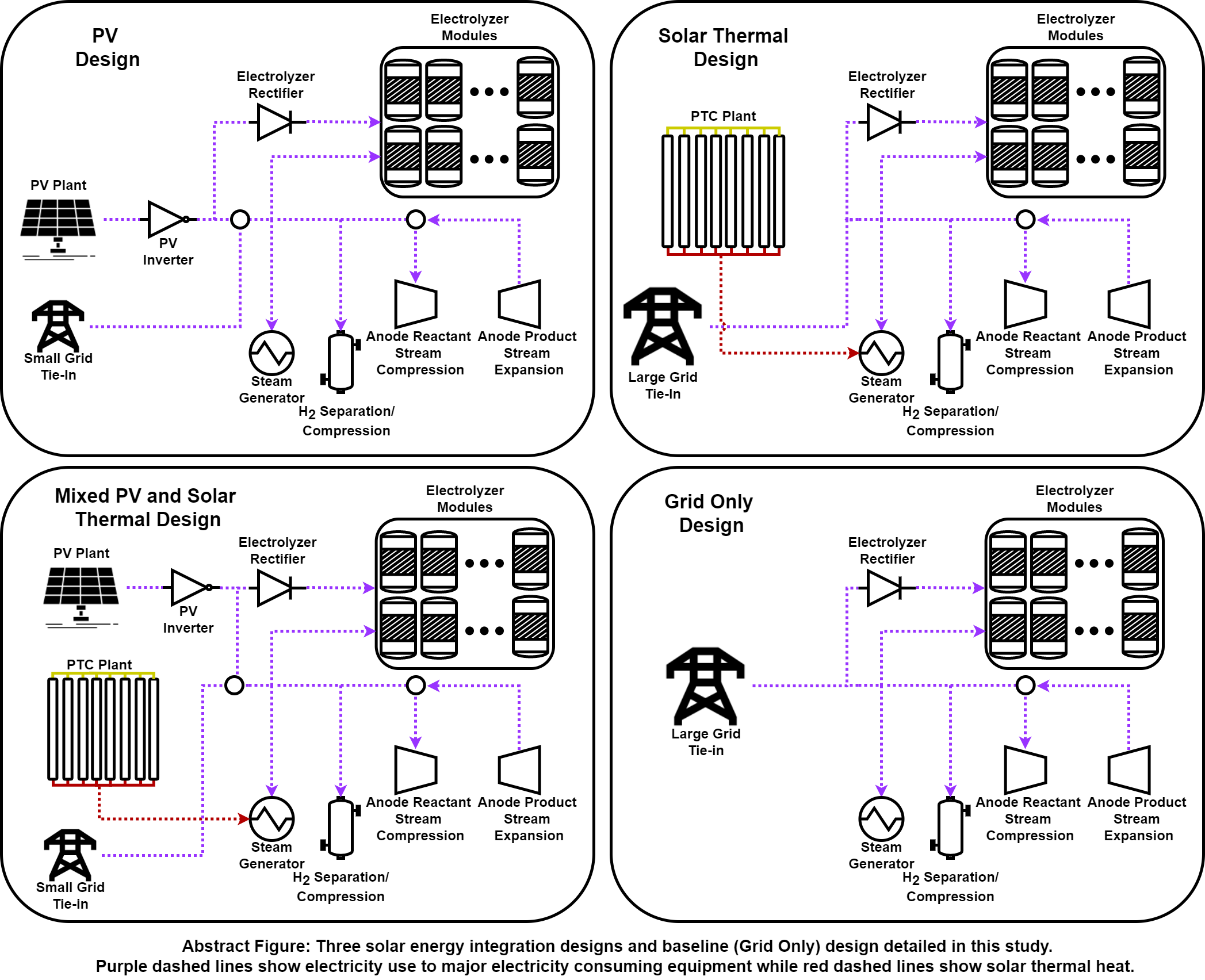

This study focuses on the analysis of different feasible solar energy integration methods for a solar-to-hydrogen high temperature steam electrolysis (SH-HTSE) plant. Three solar energy integration scenarios and one baseline, Grid Only scenario are analyzed as shown in the Abstract Figure. The scenarios are compared using operational, economic, and environmental metrics. Two scenarios, the PV Design and Mixed PV and Solar Thermal Design (Mixed Design), only use renewable electricity from solar PV while producing hydrogen, limiting their production to daytime. The Mixed Design supplements the heat requirement for steam generation with solar thermal energy while the PV Design uses electric resistive heating for steam generation. Despite using resistive heating for steam generation, the PV Design is still more electrically efficient than proton exchange membrane electrolysis due to efficient heat recuperation from the product streams. The Solar Thermal Design and Grid Only Design produce hydrogen continuously using electricity provided from the grid. When possible, the Solar Thermal Design uses solar thermal heat for stream generation, and otherwise uses electric resistive heating. Results show that if tax credits from the Inflation Reduction Act are included, the PV Design is the most economical choice with a levelized cost of hydrogen value close to $3/kg H2 produced. If tax credits aren’t included the Solar Thermal Design is the most economical choice but this is at the expense of carbon emissions with both the Solar Thermal Design and Grid Only Design outputting more carbon emissions than steam methane reforming due to the current carbon heavy nature of the electrical grid. The main downside of the PV and Mixed Design is that they will have to ramp production to meet the electric generation from PV. This operation is investigated through dynamic modeling of the SOECs from hot standby mode to full production to show how a multi-megawatt electrolysis system could follow generation without compromising the SOECs’ health. Overall conclusions from this work highlight that using PV for the electric input to the SH-HTSE plant can demonstrate promising operational, economic, and environmental results and should be investigated further for sustainable, clean hydrogen production.