(222h) A Novel Electric Reactor Concept for Methane to Acetylene Conversion

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Topical Conference: Decarbonization of the Chemical Industry through Electrification

Decarbonization by Electrification: Reactors & Reactions 1

Tuesday, November 7, 2023 - 2:41pm to 2:59pm

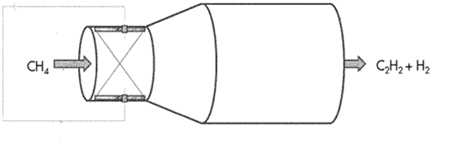

Abstract: With renewable electricity becoming a highly widespread and accessible form of energy, electrification of chemical processes presents one of the most promising transition paths to low carbon footprint manufacturing of chemicals. A large extent of chemical processes in industry are endothermic in nature and the necessary heat is currently provided by burning fossil fuels. The conversion of methane into acetylene has gained more attention in recent years and is one of the promising pathways to create acetylene. This conversion is favorable at high temperature (>1900 0C) at very low residence times (<1 millisec), which poses some challenges. The basic technology using an electric arc reactor, however, has been around for many decades [1]. Due to heterogeneity of the temperature and residence times, significant amounts of carbon is formed, which decreases the selectivity towards acetylene in conventional reactor concepts. The current work shows a novel reactor concept where necessary heat is provided directly via electricity (joule heating) for a high temperature chemical conversion of methane to acetylene [2]. The concept involves flow of methane through structured packing or obstacles of arranged mesh or wire structures directly heated by green electricity [fig.1]. Such concepts are also very recently published in literature for catalytic conversions [3-5]. However, a detailed computational fluid dynamics (CFD) based numerical simulations coupled with developed reaction kinetics shows optimal conversion and selectivity of methane to acetylene at the desired temperature and residence times, if these structures are arranged in a specific configuration. The concept also shows added advantage with respect to scale up, modularity, residence time distribution and lower pressure drop than conventional reactor concepts.

- High-Temperature Pyrolysis of Hydrocarbons. 1. Methane to Acetylene Industrial & Engineering Chemistry Process Design and Development, A. Holmen, O. A. Rokstad, and A. Solbakken, 1976 15 (3), 439-444

- A method of producing C2H2 –De Shauvik, P. van Bavel Alexander, European Patent; EP 3 845 513, 2020

- Enhancing CO2methanation over a metal foam structured catalyst by electric internal heating - Dou L, Yan C, Zhong L, Zhang D, Zhang J, Li X, Xiao L - Chem Commun, 2019

- A compact catalytic foam reactor for decomposition of ammonia by Joule heating mechanism- A Badakhsh, Y Kwak, YJ Lee, H Jeong, Y Kim, H Sohn - Chemical Engineering Journal, 2021

- Electrified methane reforming: A compact approach to greener industrial hydrogen production - Wismann ST, Engbæk JS, Vendelbo SB, Bendixen FB, Eriksen WL, Aasberg-Petersen K, Frandsen C, Chorkendorff I, Mortensen PM. Science, 2019.