(197bl) Predicting Percolation in e-Waste Leaching Using a Coarse-Grained Molecular Flow Model

AIChE Annual Meeting

2023

2023 AIChE Annual Meeting

Computational Molecular Science and Engineering Forum

Poster Session: Computational Molecular Science and Engineering Forum

Monday, November 6, 2023 - 3:30pm to 5:00pm

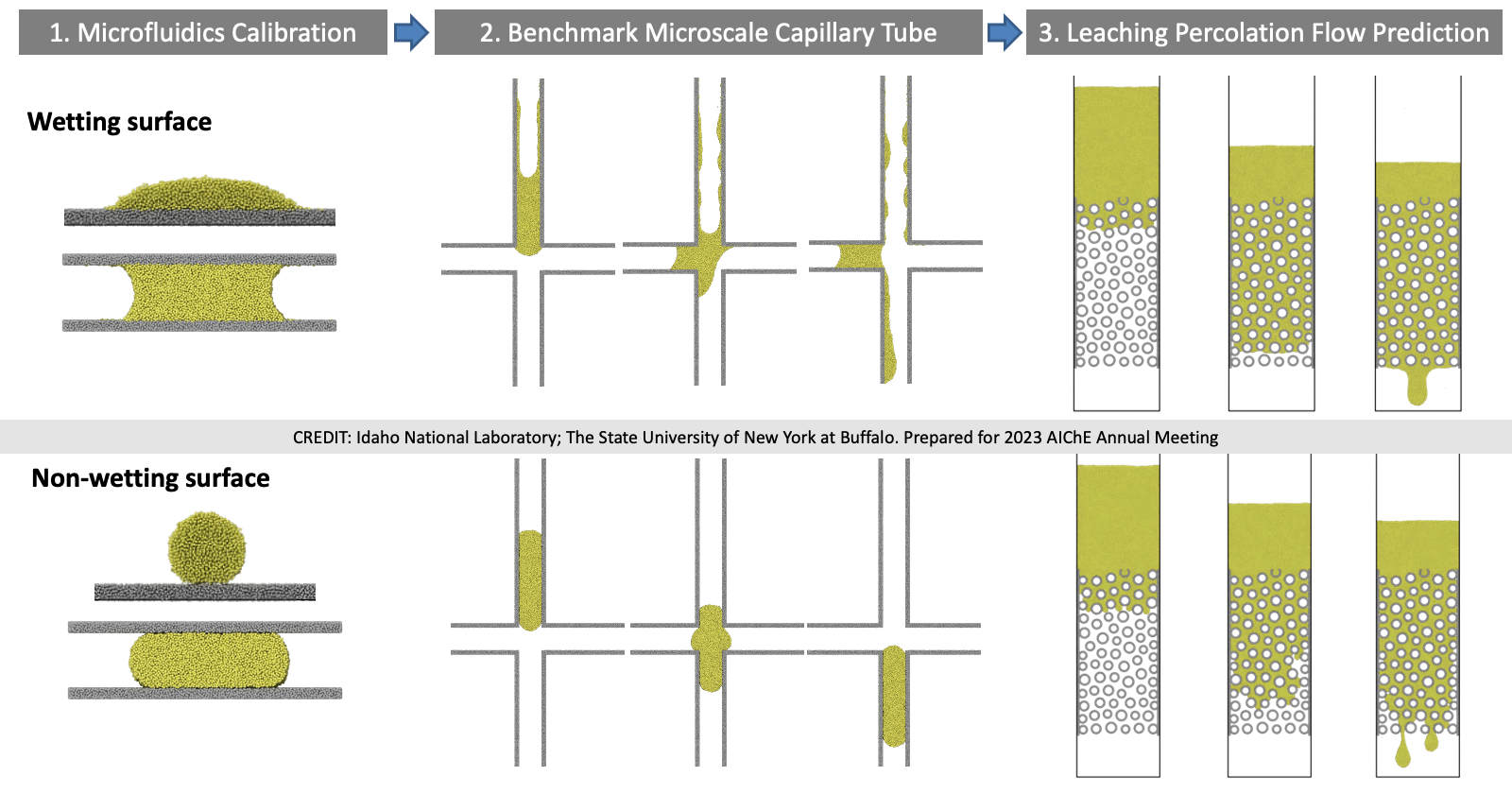

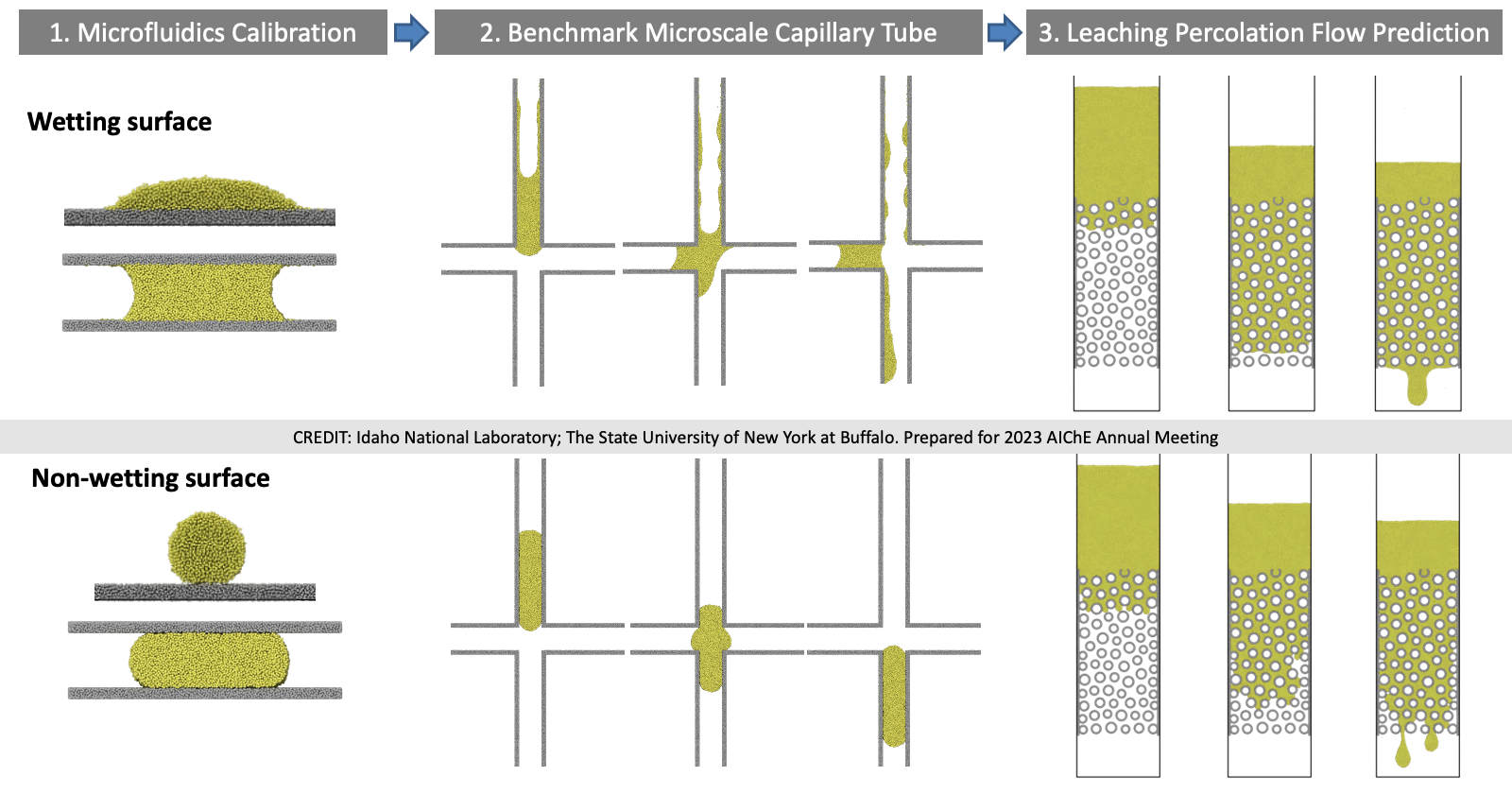

Recovery and recycling of electronic waste (e-waste) involves leaching to dissolve valuable metals as a key intermediate process. Preprocessing is required to mechanically size reduce and screen the raw e-waste to generate fine powders with improved metal concentration as feedstocks for leaching. The leaching efficiency largely depends on narrow particle size distribution (PSD), high sphericity and moderate surface wettability of the powders to form uniform pore networks and high-saturation percolation. However, the current e-waste leaching efficiency is not well understood or predicted, because of the poor powder qualities (wide PSD, large aspect ratio (AR) shapes, etc.); those result in heaps with preferential flow paths (short circuit) and low pore saturation, dissolving low metal content and requiring more re-circulations – a critical barrier for scaleup of the process. Improving leaching by using high-quality powders can be guided by computational simulations of percolation in realistic powder packing, which is relatively an unexplored area. Classical molecular dynamics (MD) simulations are not possible for the computing cost required for the relevant length and time scales. Continuum-based computational fluid dynamics (CFD) simulations are also not suitable, as they are not capable of resolving micron-scale pore-mediated wetting. This work uses a many-body dissipative particle dynamics (mDPD) model as a coarse-grained molecular flow model for multiphase simulations of percolation through pore networks formed by micron-sized e-waste powders. The model parameters are calibrated to exhibit the properties of realistic leaching fluids. Parametric simulation studies focusing on the influence of surface wettability and pore size and shape on the flux and saturation during percolation are performed. Criticality of the tested fluid properties and powder attributes as well as the processing parameters on the percolation performance will be reported and discussed.

Checkout

This paper has an Extended Abstract file available; you must purchase the conference proceedings to access it.

Do you already own this?

Log In for instructions on accessing this content.

Pricing

Individuals

| AIChE Pro Members | $150.00 |

| AIChE Emeritus Members | $105.00 |

| AIChE Graduate Student Members | Free |

| AIChE Undergraduate Student Members | Free |

| AIChE Explorer Members | $225.00 |

| Non-Members | $225.00 |