(647e) Blue H2 Production of 12-Bed PSA Process Integrated with CO2 Absorption Process from Smr Syngas

AIChE Annual Meeting

2022

2022 Annual Meeting

Separations Division

PSA/TSA and Adsorption Processes Design and Scale-up

Thursday, November 17, 2022 - 1:34pm to 1:50pm

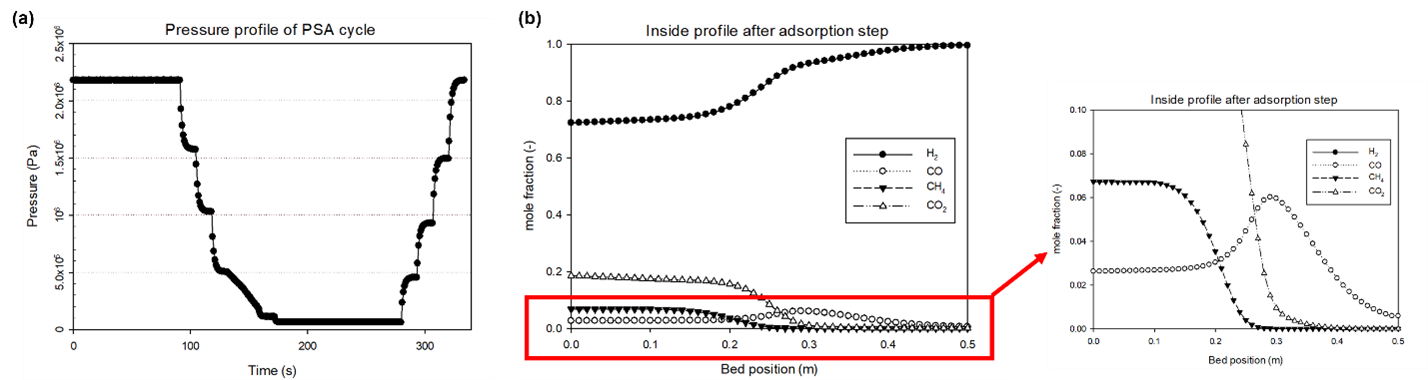

Herein, as a first step, the dynamic model of 12-bed H2 PSA process is developed, which is widely used in petrochemical industries to produce H2 from a reforming gas. The 12-bed PSA process using the layered beds with activated carbon and zeolite is operated at a 24-step cyclic sequence. The developed dynamic model is validated with industrial operating data. When dry-based reforming gas (H2/CO/CH4/CO2; 72.25/2.62/6.71/18.42%) is used at real operating pressure and flowrate, H2 purity of 99.99+% with 88+% recovery can be achieved, which agrees well with the real operating result. The role of each adsorptive layer was analyzed as a bulk separator or a purifier.

Then, a highly efficient blend-amine process, which is installed before the PSA process as a pre-combustion CO2 capture, is optimized to achieve 90-99 % CO2 capture with 99+ % purity from SMR syngas. Finally, the 12-bed PSA process integrated with the CO2 capture process using blend-amine is studied. The optimal operating condition for the present 12-bed PSA process is affected by CO2 capture rate in the range of 90 to 99% because feed composition and flowrate are significantly changed. Therefore, depending on the capture rate, the performance and dynamic behavior are analyzed to gain the insights of performance and dynamic behavior by using the verified dynamic model. Due to the complexity of the integrated process optimization by multi-operating variables, a machine learning technology is applied to find the optimum operating conditions at each CO2 capture rate.

References:

- Y. Park., J.H. Kang., D.K. Moon., Y.S. Jo, C.H. Lee., Chem. Eng. J. 408 (2021) 127299.

- D.K. Moon, D.G. Lee, C.H. Lee, Appl. Energy. 186 (2016) 760.