(532h) Hydrotreatment of Soybean Oil for Green Fuels with Ni-Mo/Zeolite Y Catalysts

AIChE Annual Meeting

2022

2022 Annual Meeting

Catalysis and Reaction Engineering Division

Poster Session: Catalysis and Reaction Engineering (CRE) Division

Wednesday, November 16, 2022 - 3:30pm to 5:00pm

Hydrotreated vegetable oil is gaining popularity as a renewable and environmentally friendly fuel with less carbon emission. In this work, the hydrotreatment of soybean oil to liquid alkane fuels was conducted with bimetallic Ni-Mo catalysts supported on zeolite Y, denoted as Ni-Mo/Y. Incipient wetness impregnation was employed to prepare Ni-Mo/Y. Prior to the hydrotreatment process, Ni-Mo/Y were activated in the hydrogen atmosphere at 550°C, denoted as Ni-Mo(R)/Y. The hydrotreatment of soybean oil in presence of various Ni-Mo(R)/Y catalysts and using decalin as solvent was performed in a semi-batch reactor equipped with a magnetic stirrer at 460 rpm for 6 h. Activated and spent catalysts were characterized by XRD, SEM, XPS, ICP-OES, H2-TPR, NH3-TPD, and N2 physisorption analyzer. The liquid phase products were analyzed qualitatively by FT-IR and GC-MS, while the yield and selectivity were determined quantitatively by GC-FID.

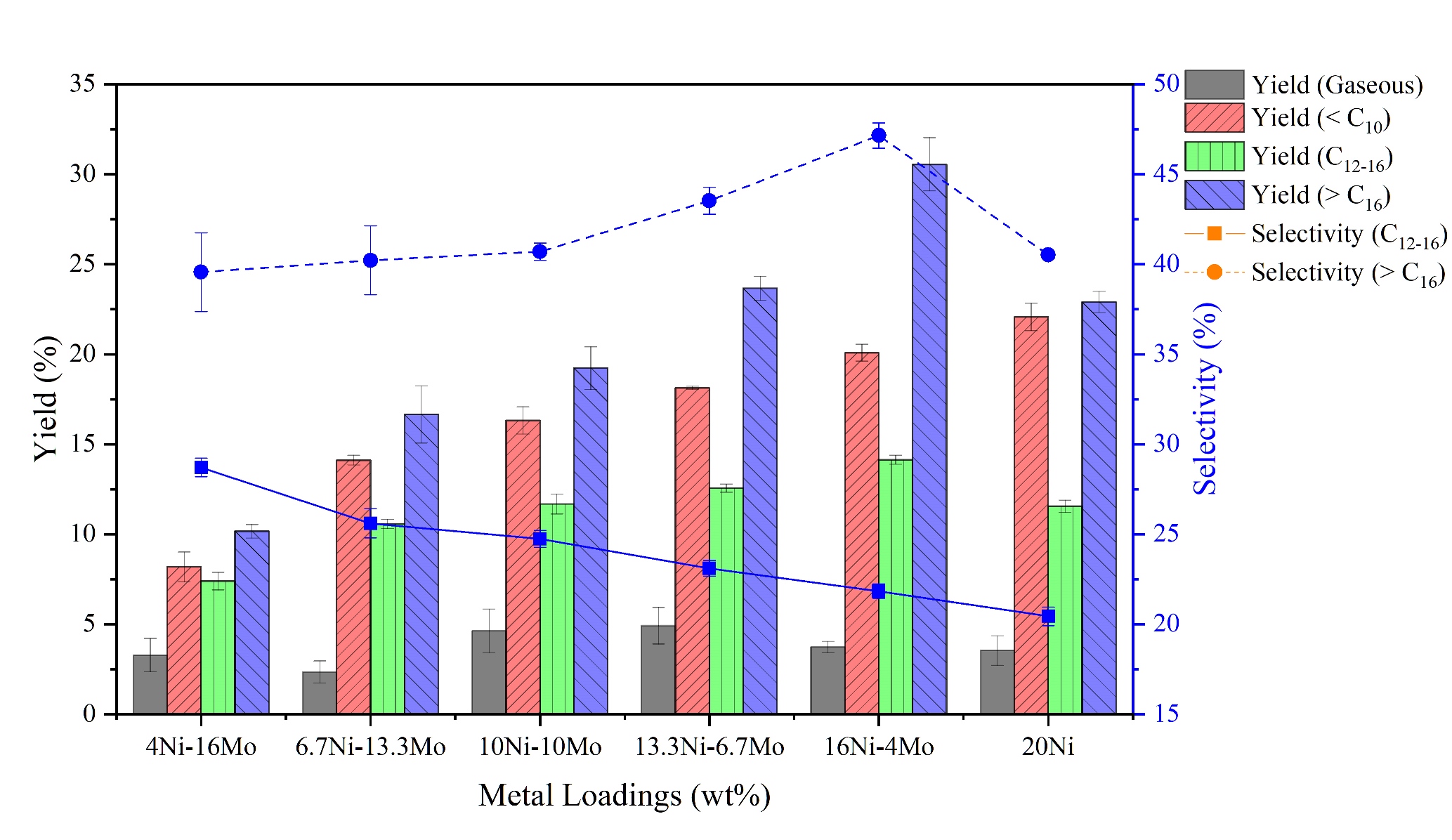

In terms of the degree of deoxygenation, catalysts obtained with Ni/Mo at 4 by mass performed better and even superior than Ni monometallic catalysts. Figure 1 shows the catalytic performance of Ni-Mo(R)/Y in deoxygenation and the distribution of produced alkanes, while the metallic loadings were kept at 20 wt% based on the mass of zeolite Y support. In general, increasing total metal loadings on zeolite Y could enhance the catalytic performance in deoxygenation reaction. Overall, the hydrotreatment of soybean oil catalyzed by 32Ni-8Mo(R)/Y at 350°C and 40 bar could completely remove the oxygen atoms of the triglycerides, possessing the highest yield to alkane products and the best selectivity to the middle distillate simultaneously.