(335d) How Critical Is the Wall Cohesion for Flow of Cohesive Powders? the Cases of Tablet Press Feeder and Hopper Screw Feeder

AIChE Annual Meeting

2022

2022 Annual Meeting

Particle Technology Forum

Pharmaceutical Powder and Particulate Systems

Tuesday, November 15, 2022 - 1:24pm to 1:42pm

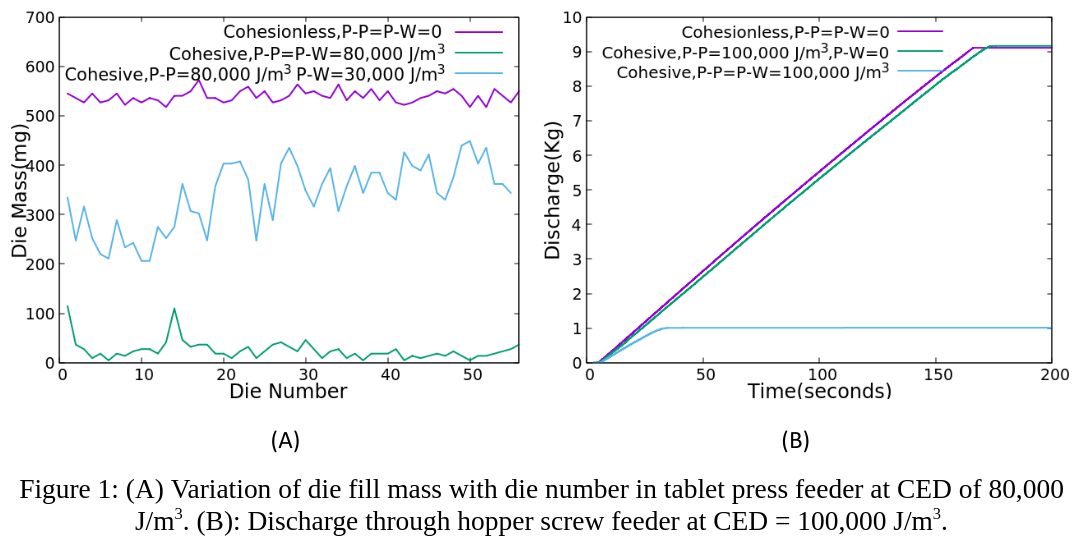

DEM studies have been conducted for the TPF and HSF using LIGGGHTS public where SJKR2 (Simplified JKR) model has been used for cohesion. The particle-wall cohesion (P-W) was varied from zero to that of the particle-particle cohesion (P-P) and the effect on the process performance was studied. For the TPF, if the P-W cohesion is significantly smaller than the P-P cohesion, large variations in the mean tablet mass and relative standard deviation are observed, as shown in Figure 1(A). A similar effect has been observed for the HSF as well. In this case, even a highly cohesive system (with CED = 100,000 J/m3) can flow well if the wall cohesion is minimum. However, the flow will stop by bridge formation if the P-W and P-P cohesion values are of comparable magnitude, as shown in Figure 1(B). Many more interesting features are also revealed in these simulations which will be presented in this talk.

[1] W.R. Ketterhagen, "Simulation of powder flow in a lab-scale tablet press feed frame: Effects of design and operating parameters on measures of tablet quality", Powder Technol. 275 (2015) 361–374. https://doi.org/10.1016/j.powtec.2015.01.073.

[2] J.W. Fernandez, P.W. Cleary, W. McBride, "Effect of screw design on hopper drawdown of spherical particles in a horizontal screw feeder", Chem. Eng. Sci. 66 (2011) 5585–5601. https://doi.org/10.1016/j.ces.2011.07.043.

[3] Q.F. Hou, K.J. Dong, A.B. Yu, "DEM study of the flow of cohesive particles in a screw feeder", Powder Technol. 256 (2014) 529–539. https://doi.org/10.1016/j.powtec.2014.01.062.