(163f) Development of Chemically Degradable Epoxy Resins for Upcycling Carbon Composites By Using Molecular Dynamics

AIChE Annual Meeting

2022

2022 Annual Meeting

Engineering Sciences and Fundamentals

Poster Session: Interfacial Phenomena (Area 1C)

Monday, November 14, 2022 - 3:30pm to 5:00pm

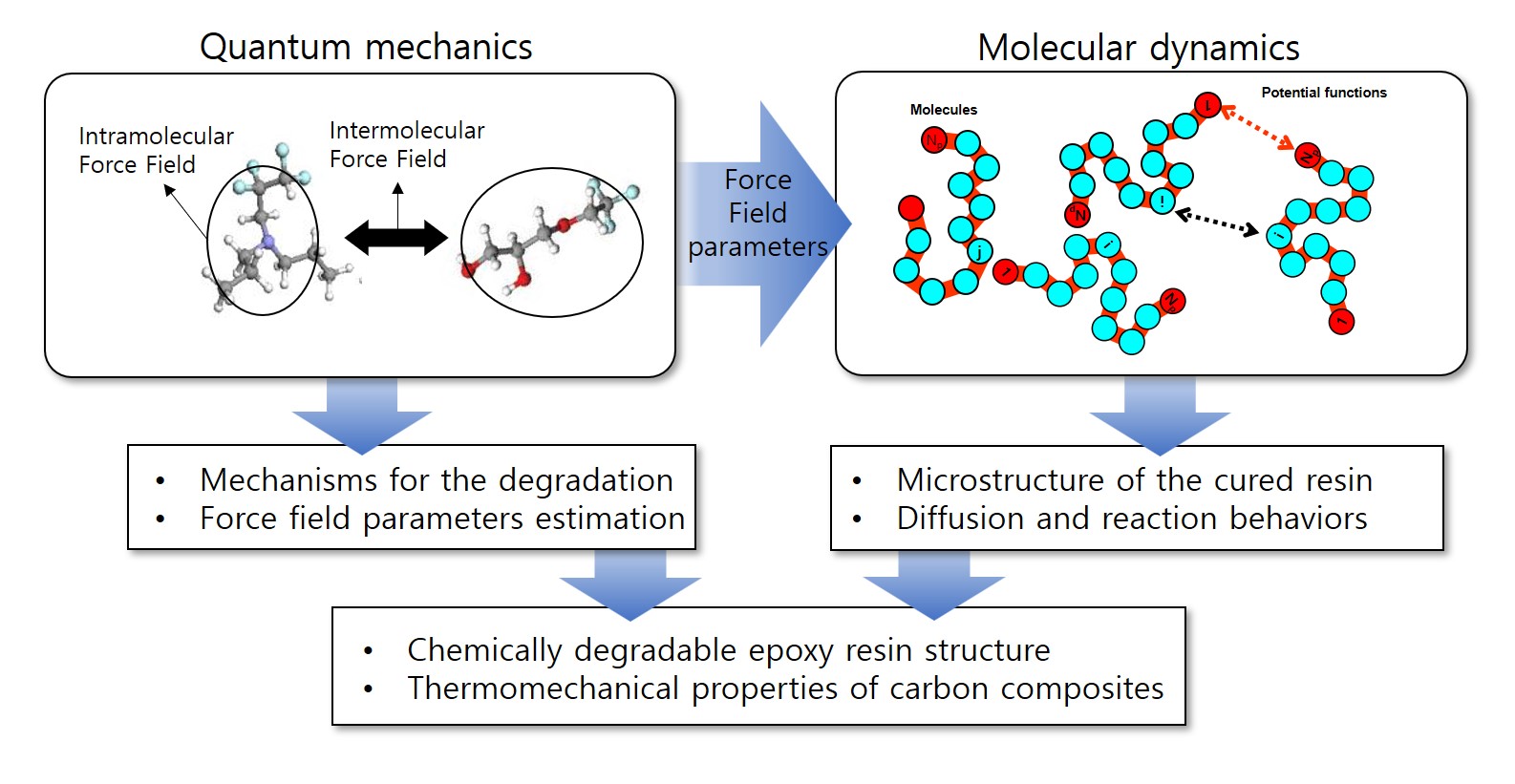

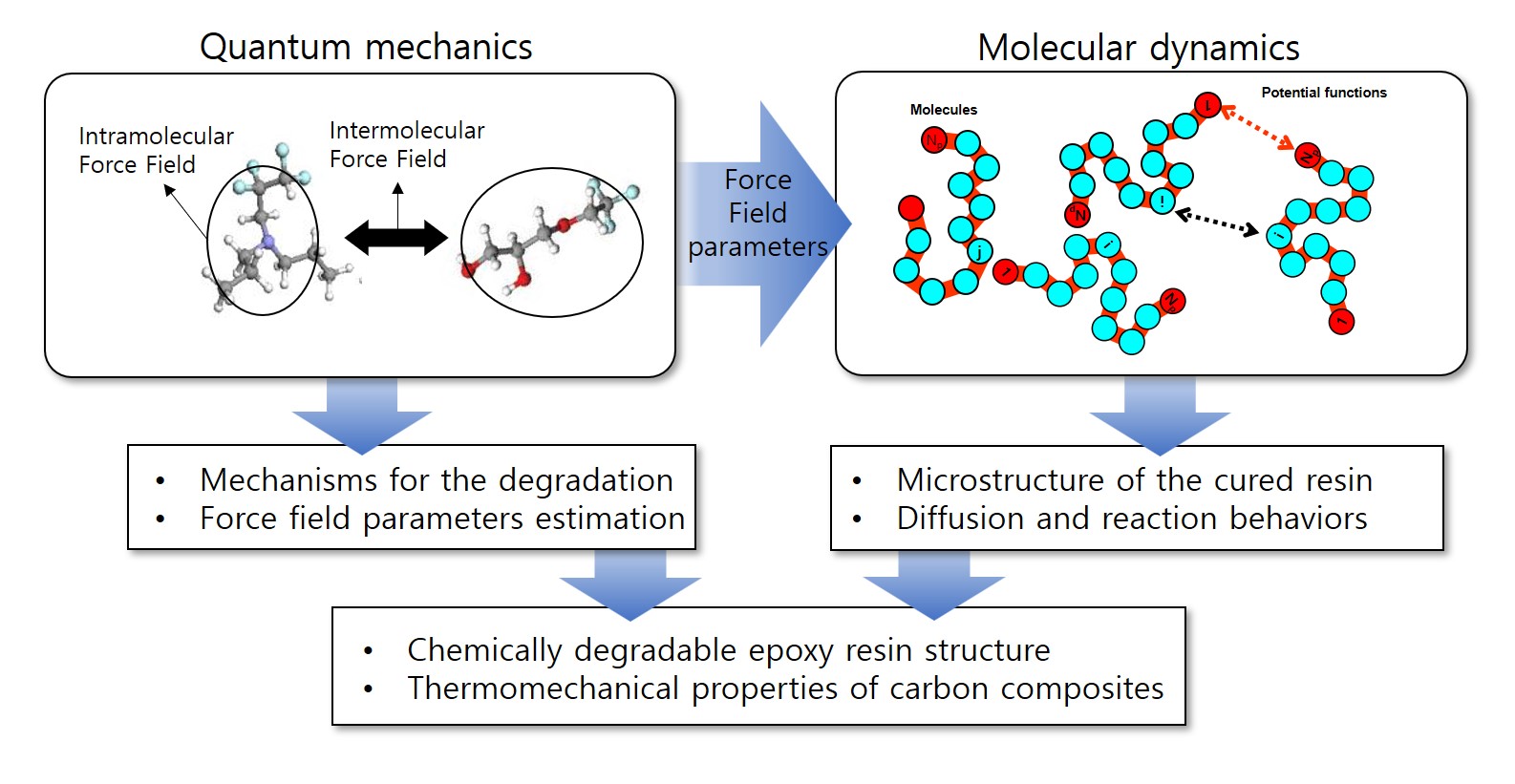

Carbon composite materials, where the carbon fiber textile is reinforced by the epoxy resin, have been widely used for the broad range of industries including mobility, air transport, renewable energy area, etc. This massive usage of the carbon composite materials is expected to the accumulation of the waste, which may become a critical problems in our society. Therefore, nowadays, many researchers have been investigated the degradable materials which have the level of thermochemical properties as similar as the carbon composites to correspond the needs. Among the various researches and developments, we focus on developing the chemically degradable epoxy resin by modifying the polymer structures with the degradable functional groups (e.g., by thermal hydrolysis). The degradable resins are expected to bring the way of treating wasted bulk resins as well as recycling the extracted carbon fibers to reduce the production costs. In this study, we have developed the chemically degradable epoxy resins by using molecular dynamics. If the carbon composites are treated with the solutions with reaction agent (RA), the RA diffuses into the entangled structures of resin via solution channel, which is made by the additions on the curing stage. Consequently, the RA chemically decomposed the functional groups on the epoxy resins, which degrades the network structures of cured resin. Here, we have developed molecular models by using coarse-grained molecular dynamics, which simplifies the detailed chemical structures while retaining the essential physics to model the large scale of the cured bulk polymers. Self-diffusion coefficient of RA was estimated by tracking the movement of RA as a function of microstructures of the bulk by tuning the chemical structures of resins, curing agents as well as functional groups. To enhance the accuracy of the molecular models, chemical reaction mechanism and required degradation level of energy was investigated by the quantum mechanics (QM) simulations, which are consequently utilized to the reactive molecular models by using a stochastic reaction model based on the Monte-Carlo algorithm. Here, we observed that the thermochemical properties can be affected by the the degradation rate. To enhance the rate of the degradation while keeping the thermomechanical properties, we have modified the microstructures of the cured resin by adding the water channel. A certain additions during the curing process may form the phase separation to make the tortuous path if the addition can be decomposed after the curing. With this phenomena, we have modeled channeled resin, which increases the rate of degradation with less reduction of the thermomechanical properties.