Dust explosions are a major hazard of unloading and conveying operations. Protect your facility from explosions with venting panels, flameless venting systems, and chemical suppression systems.

Many chemical process industries (CPI) facilities receive raw materials in bulk quantities in trucks or railcars. Depending on the distance to the downstream equipment and the nature of the product, the material can be unloaded via open conveyors, such as belt conveyors, or enclosed conveyors, such as drag-chain, screw, and pneumatic conveyors.

For example, raw food ingredients like sugar and flour are almost always transported in enclosed conveyors to prevent foreign materials from entering the product stream. Cleanability and 100% discharge of product are also important in food applications, which makes pneumatic conveying systems a popular choice, especially over shorter distances. Products like grain and coal are typically transferred by mechanical conveyors, such as screw conveyors and drag-chain conveyors.

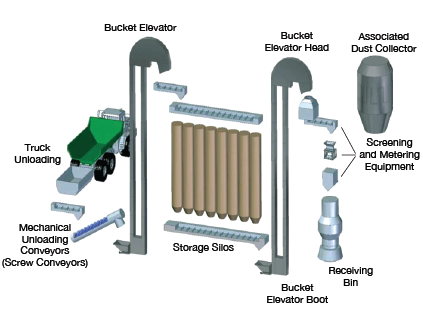

▲Figure 1. Many facilities receive feedstock in bulk quantities by truck and use conveyors to transfer material to downstream equipment.

The unloading process (Figure 1) is particularly critical because any sparks or ignition sources introduced at this point may travel to the entire downstream process. To help prevent explosions, plant personnel should be trained to recognize combustible dust explosion risks and methods to mitigate those risks. Product delivery protocols for truck drivers and unloading supervisors should be established — even for protected systems — to prevent false triggering (i.e., inadvertent over-pressuring, which may cause explosion vents to rupture or chemical suppressant to be released, etc.). And, conveying processes must be designed and operated in a way that prevents and/or mitigates combustible dust explosions. National Fire Protection Association (NFPA) Standard 652 (1), Section 9.5, provides guidance on training and hazard awareness.

NFPA Standard 69 (2) defines various prevention methods, such as deflagration prevention by reducing the concentration of oxidant or combustible material, and pre-deflagration detection and control of ignition sources. These measures can eliminate the requirement for explosion protection in certain systems, as well as reduce downtime caused by deflagrations in a protected system. In cases where prevention methods will not suffice, explosion protection systems allow for safer operation and reduce the probability of deflagration events in downstream equipment.

Explosion prevention methods

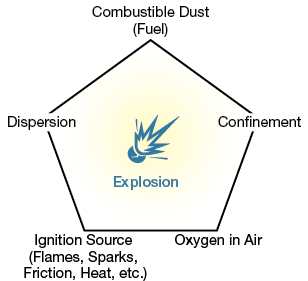

▲Figure 2. A pentagon depicts the five elements needed to create an explosion: combustible dust (fuel), dispersion of dust, confinement of a dust cloud, ignition source (flames, sparks, friction, heat, etc.), and oxygen.

The combustible dust explosion pentagon (Figure 2) is a useful graphic for understanding the risks associated with a particular process. The pentagon identifies the five elements necessary to create an explosion: combustible product (fuel), dispersion of dust, confinement of a dust cloud, ignition source, and oxygen. The risk of combustible dust explosions can be eliminated if any one (or more) of the pentagon elements can be entirely eliminated.

Proper operating procedures and equipment configuration can reduce or prevent ignition hazards that might otherwise spread through the conveying system and create a combustible dust explosion risk. For example, allowing trucks to cool down before starting the unloading process can reduce the ignition hazards from hot brakes, hot exhaust pipes, etc. All unloading equipment, including trucks, should be properly grounded, and a grounding monitoring system should be installed to protect against static discharges. Magnets, screens, and sifters should be installed in the unloading process to remove foreign materials, another common ignition source. Conveyors have...

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.