A good understanding of steam-turbine operation and power generation cost can help improve overall cogeneration profitability. This article describes the basic economics behind cogeneration.

Cogeneration — the process of using steam to turn turbines and generate power — allows a plant to reduce its reliance on external electrical energy purchases. This article discusses best practices for the selection, operation, integration, and control of steam cogeneration systems.

What is cogeneration?

A typical fossil-fuel power plant has an average thermal-to-power efficiency of 35–45%, because its steam turbine can only extract so much electrical energy from high-pressure steam, and because the low-pressure steam that exits the turbine cannot be used. Therefore, the steam exiting the turbine must be condensed, and its potential energy is lost.

Industrial plants, however, have a competitive advantage over power plants because they have several process units that can use the lower-pressure outlet steam, which eliminates the need for inefficient steam condensing.

In a cogeneration system, steam that passes through the turbines is maintained at an outlet pressure high enough to be used by process units. Because energy at the turbine outlet is re-used, cogeneration systems have overall efficiencies that can be higher than 85%, which allows industrial plants to generate electrical power at lower-than-market costs.

The thermodynamics of cogeneration

An understanding of the basic thermodynamic terms and concepts is needed to analyze a turbine’s energy conversion efficiency.

- Specific enthalpy (h) is the amount of energy per unit mass of steam. It is usually expressed in BTU/lb, MWh/kg, or GJ/kg.

- Specific heat of vaporization (∆hlg) is the amount of energy per unit mass required to effect a change of state from water to steam at constant pressure. It is usually expressed in units of BTU/lb, MWh/kg, or GJ/kg.

- Specific entropy (s) can be thought of as the potential energy of steam, where a lower entropy value means higher potential energy and a higher entropy value means a lower potential energy. For a closed system with no losses, the overall system entropy can only increase or stay constant (sfinal ≥ sinitial).

- Steam turbine efficiency (ηeff) is the ratio of the actual work produced by the turbine to the maximum amount of work that the turbine could extract if the process were ideal (i.e., a no-loss isentropic expansion).

A steam turbine that has a 100% isentropic efficiency is capable of extracting all of the potential power present in the steam. In this hypothetical case, the inlet entropy will equal the outlet entropy. A turbine with an efficiency of 0% is incapable of converting thermal energy into power. This is called an adiabatic process, in which the inlet enthalpy and the outlet enthalpy are equal.

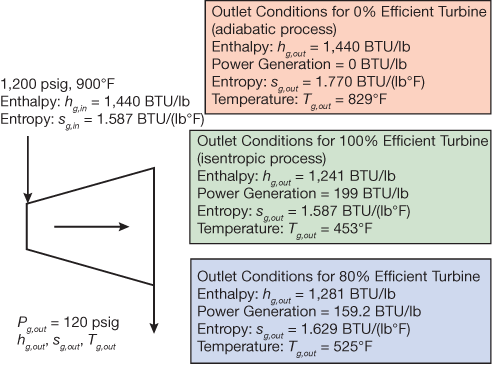

▲Figure 1. The amount of power generated and the steam outlet conditions will vary for a steam turbine at 0%, 80%, and 100% efficiency.

Figure 1 shows how power generation will vary as the steam turbine efficiency changes. To calculate the amount of power generated and outlet conditions of the steam turbine, follow these three steps:

- Determine the outlet enthalpy for a 100% efficient turbine (sin = sout).

- Calculate the amount of energy extracted by the turbine at 100% efficiency (∆hisen = hg,in – hg,out,isen) and multiply that value by the turbine efficiency to determine the real amount of power extracted.

- Recalculate the outlet enthalpy (hg,out= hg,in – ƞeff∆hisen) and use a steam table to determine other steam conditions.

Types of steam turbines

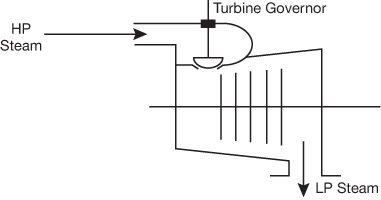

▲Figure 2. In a backpressure turbine, high-pressure (HP) steam is fed into the turbine and low-pressure (LP) steam is fed from the outlet of the turbine into another process.

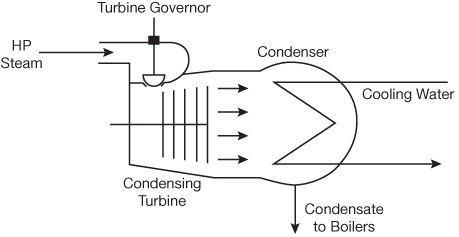

▲Figure 3. In a condensing steam turbine, high-pressure (HP) steam is fed to the turbine and the outlet steam is condensed.

There are two main types of steam turbines: backpressure and condensing. In a backpressure turbine, the outlet of the turbine is connected to a header that distributes steam to the various process users (Figure 2). In a condensing turbine, outlet steam is sent to a condenser operating under vacuum (Figure 3).

These simple backpressure or condensing turbines are typically only used in simple steam systems. In more-complex applications, multiple backpressure turbines can be combined in series to form a single turbine with multiple steam outlets. Turbines with multiple outlet ports are called extraction turbines; these are frequently used for cogeneration because they allow steam to be extracted at one or more intermediate points in the turbine casing.

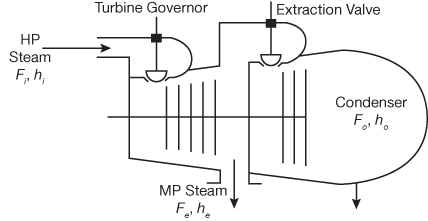

▲Figure 4. This condensing steam turbine has one medium-pressure (MP) extraction point. Throttling the extraction valve can control the MP extraction steam flow, and with it, the pressure of the MP header.

Condensing turbines with extraction. An example of a condensing steam turbine with one medium-pressure (MP) extraction point is shown in Figure 4. In this extraction turbine, high-pressure (HP) steam produced by the boilers is fed to the steam turbine, and the turbine governor valve controls the flowrate of the inlet steam flow to the turbine. The MP extraction steam flow is controlled by throttling the extraction valve, where opening the extraction valve decreases the extraction flow and vice versa. Modulating the steam flow at the extraction point likewise controls the pressure of the MP header.

There is virtually no steam production or loss in a steam turbine. Therefore, in Figure 4, the inlet steam flow (Fi) is equal to the sum of the extraction steam flow (Fe) and the condenser flow (Fo):

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.