The design of robust pharmaceutical crystallization processes has been of high interest in academia and industry for the last decade (Nagy and Braatz, 2012). Continuous-flow tubular crystallizers have shown potential for high reproducibility and process efficiency at low capital and production cost (e.g., Alvarez & Myerson, 2010; Lawton et al., 2009; Vacassy et al., 2000). A recent advance that combines the advantages of continuous and batch crystallizers is the air/liquid slug-flow crystallizer (Eder et al., 2010; 2011; 2012; Jiang et al., 2014; 2015) which has unique advantages including narrow residence time distribution, no stirrer generating secondary nucleation, and easy post-crystallization separation. The potential application of slug-flow crystallization in the final stage of pharmaceutical manufacturing is the focus of this design study.

Similar to batch crystallization, the design of a robust slug-flow crystallization process comes from a good understanding of how the supersaturation profile is affected by the design variables, such as the method and rate of supersaturation generation, and the corresponding implementation. For example, supersaturation should be minimized so as to avoid impurity incorporation and secondary nucleation (e.g., Jiang et al., 2012; 2014), which is important for slug-flow crystallization with its possibly short residence time (on the order of minutes) (Eder et al., 2012; Jiang et al., 2014) and with fast heat transfer associated with the large surface area-to-volume of tubular crystallizers.

Unlike past studies that involve mathematical modeling or analysis of similar continuous crystallizers (e.g., Eder et al., 2010; Kubo et al., 1998), this study only analyzes an experimental demonstration (Jiang et al., 2014) but also investigates the effect of and optimizes numerous design variables (e.g., number of heat exchangers, length of tubing in each heat bath/exchanger, mass flow rate through the heat exchangers) while minimizing the total equipment/material use in the design. This presentation describes the first dynamic simulation of slug-flow crystallization for a series of counterflow, concentric shell-and-tube heat exchangers.

The method of moments is combined with the numerical method of lines with a finite difference approximation to reduce the model described by four partial differential equations (balances on population, solute, and energy in both the shell and tube) to a system of ordinary differential equations. The system is to be designed so that, under normal operating conditions, the temperature drop in each heat exchanger produces an environment to minimize the maximum supersaturation, to promote molecular purity, while applying a constraint that ensures a nearly maximum yield.

Operating so that the exit concentration is near the minimum concentration provides the desired yield. The optimal crystal size is specified by the upstream nucleation rate. Excessive length of the tubes should be avoided, as that would introduce a time delay in the process dynamics that is undesirable for closed-loop control. The control objective is to minimize the maximum supersaturation in the system by manipulating the flowrate and inlet temperature of cooling water in each heat exchanger to suppress the effects of process disturbances.

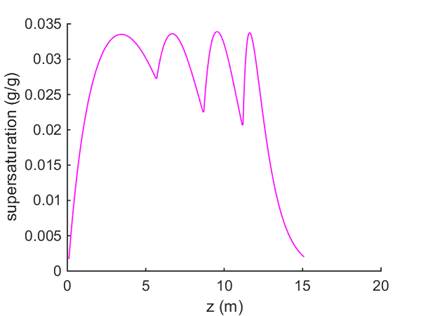

Optimal steady-state spatial profiles for the four-stage slug-flow crystallizer are shown in Figure 1. The supersaturation reaches the minimized maximum value in less than 5 meters, and returns to that maximum once in each heat exchanger. The drop in supersaturation near the outlet also occurs in less than 5 meters.

Figure 1: Supersaturation profile under steady, optimal conditions in the slug-flow crystallizer.

Investigating the dynamic response of the measured and product quality variables to disturbances, manipulations, and uncertainties provides a great deal of information and insight not available from steady-state models. The solute concentrations in the slug as it leaves each heat exchanger (?exit concentrations?) are observed to be highly sensitive to cooling water temperatures and variation in the growth kinetics. The cooling water flowrates have relatively low effectiveness as manipulated variables for rejection of some disturbances. Increasing the cooling water flowrate or decreasing the cooling water temperature decreases the exit concentrations. The model shows that the effect of most input disturbances on concentration, yield, and average particle size are dampened by the process design automatically.

The response of maximum and average supersaturation is of vital importance as the driving force for growth as well as nucleation. While this system is designed to minimize secondary nucleation, supersaturation levels must be kept under control to avoid the incorporation of impurities into the crystalline matrix. Cooling water temperature and flowrate are seen to have a large effect locally. Inlet conditions for the slug stream have a decreasing effect with each subsequent heat exchanger. Persistent sources of relatively large deviation are again variation in the growth kinetics.

Outlet temperatures are also compared and evaluated in terms of value as measurements for feedback control, due to the relative ease and accuracy at which temperature can be measured. Not surprisingly, the greatest effect by far on the outlet slug stream temperature is the temperature of the cooling water.

Manipulating only the cooling water flowrates is shown to be insufficient to reject process disturbances that result from the deviation of growth kinetic parameters from nominal values. Additionally, without a tight control of the inlet temperature of cooling water, manipulation of the cooling water flowrates will be insufficient to suppress that resulting deviation as well. Changes in the inlet temperature and concentration for the slug stream are less problematic; the system design is inherently robust to disturbances which occur far upstream. The robustness allows the on-line measurement of particle size, a relatively expensive and inaccurate endeavor, to be eliminated from the design of a control algorithm; particle size is not observed to be affected greatly by upstream disturbances.

In an effort to increase the output response to changes in manipulated variables, the cooling water inlet temperature should be a manipulated variable rather than allowing it to be a disturbance. That is, a lower level regulatory control system should be implemented so that the cooling water inlet temperature is controlled, with the setpoint to the cooling water inlet temperature being a manipulated variable of the higher level control system. The extra degrees of freedom from controlling not only the cooling water flowrates, but also the cooling water temperatures, greatly increase the controllability of the slug-flow crystallization process. From a design standpoint, sensitivity analysis indicates the tubing length should be increased beyond nominal design conditions to serve as a buffer to disturbances.

Several control strategies motivated by the dynamic analysis are investigated for the multivariable control of the slug-flow crystallizer (e.g., Figure 2). Neglecting particle size measurements for the reasons mentioned above, there are two measurements of interest that can be taken at the outlet of each heat exchanger: temperature and solute concentration. There are also two manipulated variables for each heat exchanger: cooling water flowrate and cooling water temperature. A variety of factors are considered in selecting the best control strategy in terms of the number of measurements, number of controllers, and which controllers receive which measurements (and control which manipulated variables). Of the eight possible measurements, the four temperature measurements are inexpensive and accurate while four measurements of solute concentration would be relatively expensive and difficult. The design of this process does not provide evidence that intermediate solute concentration measurements would be useful process control elements, and it is unlikely that the final implemented control systems design would contain those measurements. With respect to the eight manipulated variables, the inlet temperature of cooling water could be altered by applying energy to a thermal bath or, perhaps more likely, combining multiple feeds from multiple baths at Y-mixers. The cooling water temperature displays a greater effect on process dynamics than the cooling water flowrate, but incompressible fluid flowrates have the advantage of being easily and quickly controlled. After comparing the pros and cons of different control strategies, an optimal control system design will be described.

Figure 2: Example control strategy for the slug-flow crystallizer, which uses the complete set of eight measured and eight manipulated variables.

References:

Alvarez, A.J., Myerson, A.S., 2010. Crystal Growth & Design, 56, 349-369.

Eder, R.J.P., Radl, S., Schmitt, E., Innerhofer, S., Maier, M., Gruber-Woelfler, H., Khinast, J.G., 2010. Crystal Growth & Design, 10(5), 2247-2257.

Eder, R.J.P., Schmitt, E.K., Grill, J., Radl, S., Gruber-Woelfler, H., Khinast, J.G., 2011. Crystal Research and Technology, 46(3), 227-237.

Eder, R.J.P., Schrank, S., Besenhard, O., Roblegg, E., Gruber-Woelfler, H., Khinast, J.G., 2012. Crystal Growth & Design, 12(10), 4733-4738.

Jiang, M., Zhu, Z., Jimenez, E., Papageorgiou, C.D., Waetzig, J., Hardy, A., Langston, M., Braatz, R.D., 2014. Crystal Growth & Design, 14(2), 851-860.

Jiang, M., Papageorgiou, C.D., Waetzig, J., Hardy, A., Langston, M., and R. D. Braatz, R.D., 2015. Crystal Growth & Design, 15(5), 2486-2492.

Kubo, M., Kawakatsu, T., Yonemoto, T., 1998. Chemical Engineering Research & Design, 76(6), 669-676.

Lawton, S., Steele, G., Shering, P., Zhao, L., Laird, I., Ni, X.-Y., 2009. Organic Process Research & Development, 13(6), 1357-1363.

Nagy, Z.K., Braatz, R.D., 2012. Advances and new directions in crystallization control, Annual Review of Chemical and Biomolecular Engineering, 3, 55-75.

Vacassy, R., Lemaitre, J., Hofmann, H., Gerlings, J.H., 2000. AIChE Journal, 46(6), 1241-1252.