Imagine you are a new process engineer and notice that a distillation column is producing product at 99% purity. The product specification, however, is 94% purity, and you know that exceeding this mandate is a financial loss. The simulation shows that decreasing steam input by 2,000 lb/hr can reduce the purity to 95%. It is your responsibility to determine a lasting solution.

Double diamond design process

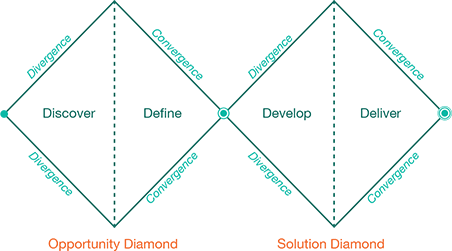

A problem-solving approach popular with user-experience (UX) designers, called the double diamond design process (1), can be applied to solve chemical engineering problems such as this distillation conundrum. The framework is a nonlinear approach that consists of four stages — discover, define, develop, and deliver — that problem-solvers can navigate back and forth between to reach a solution.

The diagram of the approach has two distinct features — the opportunity and solution diamonds and the divergence and convergence thought lines. The opportunity diamond represents exploration of the context surrounding the problem, and the solution diamond represents evaluation of viable solutions. Divergence thinking involves broad ideation, while convergence thinking involves narrowed and focused consideration.

Discover

The discover phase involves broadly considering the opportunities and limitations surrounding the problem. Create a list of potential opportunities to be captured, such as:

- avoid additional capital expense by maintaining 99% purity

- reduce the workload by gaining support and leveraging expertise of others invested in the solution

- avoid setting additional meetings and make a positive professional impression by presenting a solution at an upcoming process engineering meeting.

Create a list of potential limitations, such as:

- operators may be uncomfortable running closer to specification, as they have less room for error

- customers may be accustomed to the higher purity and may expect the same quality

- it would be embarrassing to present a faulty solution at the upcoming process engineering meeting.

Define

In the define phase, narrow your focus by constructing a specific, measurable, actionable, reasonable, and timely (SMART) goal, which should include measurable key performance indicators (KPI). For this example, a SMART goal might be: Present a validated case for reducing the steam rate at the process engineering meeting. The associated KPIs would be the task list and deadline.

Develop

In the develop phase, you evaluate the opportunities and limitations to create a list and schedule of tasks. This involves taking a close look at the opportunities to capture their value and the limitations to mitigate their risks. Tasks might include quantifying cost savings, leveraging relevant parties, and preparing a pitch, as well as conducting field tests to assure operators that product will meet specification, ensuring customers remain satisfied, and preparing an effective presentation.

Deliver

This final phase accomplishes the tasks to deliver a solution, which involves executing the task list according to the appropriate deadlines. For example,

- contact quality and sales to verify customer needs will be satisfied

- conduct steam reduction studies with operations for two days

- calculate product purities and annual monetary savings of lowering steam input by 500–2,000 lb/hr

- verify findings with the production engineer and operations supervisor

- prepare a presentation to roll out the solution

- practice the presentation.

Although this example seemed simple enough, going through the process revealed nuances that may have otherwise been missed. For example, it is critical that customers and operators are satisfied with changes. You must ensure that customers will be satisfied at lower qualities before rushing to conduct tests, and that operators trust the conservative conditions before rushing to drastic changes. While this simple scenario illustrates the benefits of the double diamond approach, its usefulness is even more pronounced as complexity increases.

1. Design Council, “A Study of the Design Process,” www.designcouncil.org.uk/sites/default/files/asset/document/ElevenLesson...(2).pdf, Design Council, London, U.K. (accessed Feb. 3, 2020).

This article originally appeared in the Young Professionals Point of View (YPOV) column of the March 2020 issue of CEP. Members have access online to complete issues, including a vast, searchable archive of back-issues found at aiche.org/cep.