This post is presented by SBE, the Society for Biological Engineering--a global organization of leading engineers and scientists dedicated to advancing the integration of biology with engineering.

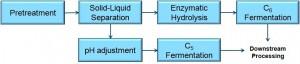

[On Location at AIChE's 2011 Annual Meeting.] One effort to increase cellulosic ethanol production efficiencies using corn stover as feedstock involves a separation of and separate processing of the solid and liquid fractions of pretreated feedstock.

In addition to facilitating an increase in the productivity of ethanol fermentation and recovery, a spit stream process opens up the possibility of diverting the C5 stream to some potentially more lucrative bioproducts.

The processes

The stover is first pretreated with dilute acid. The liquids (C5 predominantly) are then separated from the solids (C6

predominantly). The liquid stream is then adjusted to pH 5.8 and then fermented. In aseparate trial, a 2-step process where the pH was first raised to 8.5 before being lowered was trialed, with negative results. The conclusion being that additional acetic acid, a known inhibitor, was formed at the elevated pH.

The solid phase undergoes enzymatic hydrolysis with Novozyme Cellic Clec2 at 48C for 120 hours, then the resultant is fermented.

SSF and a new, secret bioagent

Simultaneous Saccharization and Fermentation (SSF) is arecent approach to cellulosic ethanol production whereby multiple organisms/enzymes are used simultaneously, versus separately as in prior processes. However, with this separate stream process, a third organism, "Bacterium A" joins the party to assist in driving the conversion of xylose to ethanol in the liquid (C5) fraction. Yields without "Bacterium A" are unacceptably low.

The results

The cellulosic (C6) portion of the fermentation proceeds in a predictable fashion, as all glucose is consumed (little inhibition-no pretreatment) and yields are constant. The goal of 85% conversion of glucan and xylan to ethanol (via glucose and xylose respectively) is also achieved. Energy use virtually the same, but water usage is slightly higher. Waste streams are mostly associated with the C5, so splitting the fractions reduces the volume of wastes produced. Dr. Aleandre Chapeaux presented the findings, and he can be reached at alex.chapeaux@nrel.gov.

All Meeting Coverage | Student Conference

Related articles

- Production of Cellulosic Ethanol (bioenergyconsult.wordpress.com)

- Challenges in Production of Cellulosic Ethanol (cleantechsolutions.wordpress.com)

- The Race to Commericalize Cellulosic Ethanol (thinkup.waldenu.edu)

- Biofuel push a bust, report hints (futureoftech.msnbc.msn.com)

Comments

It seemed to be that there were a lot of people talking about fermentation of biomass at the conference. There seemed to be a lot of developments and progress being made in what can be produced from cellulose. What was your impression - how far from market is this (or other) processes? The impression I got from people on the business side, or life-cycle analysis is that these types of processes and products are still quite a distance away from competing with traditional methods. And in some cases don't reduce carbon impact or, as you eluded to, water footprint increases. It might eventually be a niche market, but subject to full market forces it can't compete.