The biomass used to produce biofuel is most easily converted to ethanol, but that has always come with trade-offs. The primary problem: ethanol is less energy dense than petroleum-based fuels, and most vehicles can't burn more than a 15 percent mix of ethanol and standard gasoline.

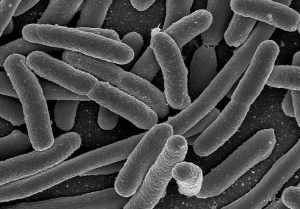

Now, however, a Rice University press release reports that researchers (The Gonzalez Group) have created a new method for rapidly converting simple glucose into butanol using the E. coli bacteria. In a paper published online in Nature, Rice's team described how it reversed one of the most efficient of all metabolic pathways, the beta oxidation cycle, to engineer bacteria that produce biofuel at a record pace.

Just how fast are Rice's single-celled chemical factories? On a cell-per-cell basis, the bacteria produced butanol, a biofuel that can be substituted for gasoline in most engines, about 10 times faster than any previously reported organism. "That's really not even a fair comparison because the other organisms used an expensive, enriched feedstock, and we used the cheapest thing you can imagine, just glucose and mineral salts," said Ramon Gonzalez, associate professor of chemical and biomolecular engineering at Rice and lead co-author of the Nature study.

Gonzalez's laboratory is in a race with hundreds of labs around the world to find green methods for producing chemicals like butanol that have historically come from petroleum. "We call these 'drop-in' fuels and chemicals, because their structure and properties are very similar, sometimes identical, to petroleum-based products," he said. "That means they can be 'dropped in,' or substituted, for products that are produced today by the petrochemical industry."

Reversing the beta oxidation cycle

Butanol is a relatively short molecule, with a backbone of just four carbon atoms. Molecules with longer carbon chains have been even more troublesome for biotech producers to make, particularly molecules with chains of 10 or more carbon atoms. Gonzalez said that's partly because researchers have focused on ramping up the natural metabolic processes that cells use to build long-chain fatty acids. Gonzalez and students Clementina Dellomonaco, James Clomburg and Elliot Miller took a completely different approach.

"Rather than going with the process nature uses to build fatty acids, we reversed the process that it uses to break them apart," Gonzalez said. "It's definitely not conventional, but it makes sense because the routes nature has selected to build fatty acids are very inefficient compared with the reversal of the route it uses to break them apart."

The beta oxidation process is one of biology's most fundamental, Gonzalez said. Species ranging from single-celled bacteria to human beings use beta oxidation to break down fatty acids and generate energy.

In the Nature study, Gonzalez's team reversed the beta oxidation cycle by selectively manipulating about a dozen genes in the bacteria Escherichia coli. They also showed that selective manipulations of particular genes could be used to produce fatty acids of particular lengths, including long-chain molecules like stearic acid and palmitic acid, which have chains of more than a dozen carbon atoms.

A reviewer at ars technica said:

Student James Clomburg...the authors are successfully leveraging decades of bacterial genetics and basic biochemistry to do this work. They really are building something using information that was pieced together by hundreds of researchers, most of whom probably didn't ever think their work would have implications for the oil economy.

It's also simply a tour de force of genetic engineering. Every time a reaction went too slowly, the researchers would pop a few extra copies of the relevant genes in to speed it up. Any sign of unwanted byproducts and they knocked out the genes that produced them.

"This is not a one-trick pony," Gonzalez said. "We can make many kinds of specialized molecules for many different markets. We can also do this in any organism. Some producers prefer to use industrial organisms other than E. coli, like algae or yeast. That's another advantage of using reverse-beta oxidation, because the pathway is present in almost every organism."